Automatic test system for circuit board

A fully automatic testing and circuit board technology, applied in the direction of electronic circuit testing, etc., can solve the problems of increasing the workload of testing personnel, increasing user cost, and long testing time, so as to reduce human errors in testing, high practical value, and testing time The effect of shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

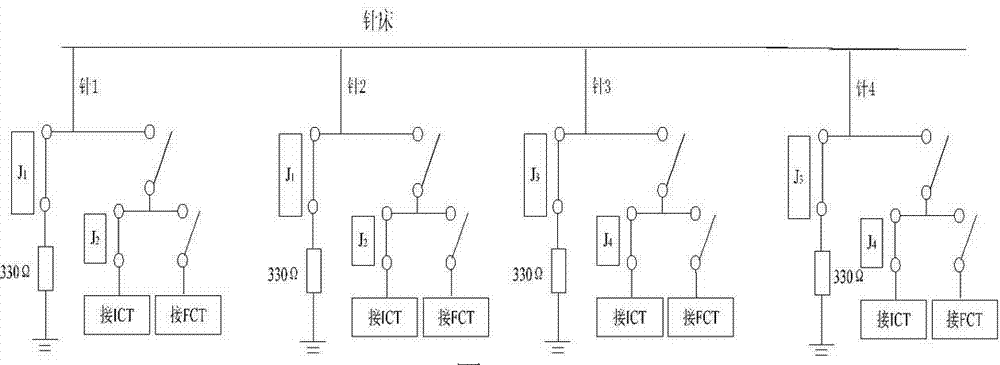

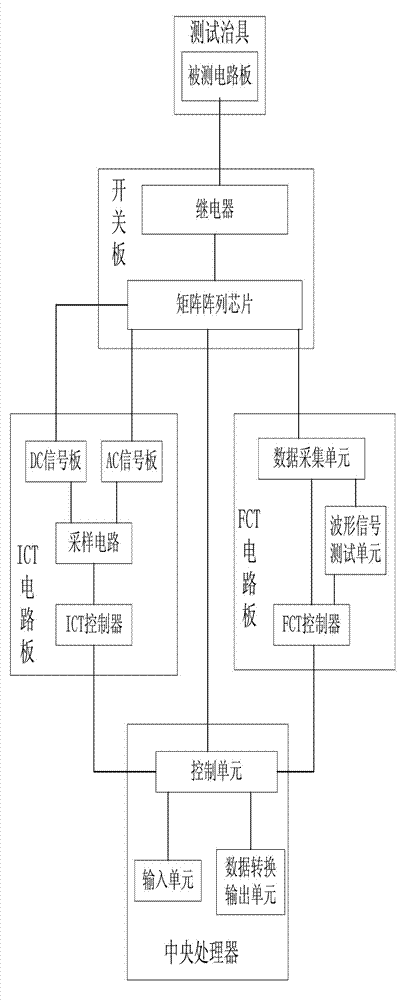

[0024] see Figure 1 to Figure 2 , a circuit board automatic testing system, including a central processing unit, a test fixture for installing a tested circuit board, an ICT circuit board for component-level testing of the tested circuit board, and a board-level test for the tested circuit board The FCT circuit board, and the switch board that realizes the conversion between component-level testing and board-level testing; the tested circuit board is placed on the needle bed of the test fixture, and several test needles are set on the needle bed corresponding to the tested circuit board, and the switch board Connect to the circuit board under test through test pins.

[0025] The central processing unit includes an input unit for inputting system paramete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com