Method for improving accuracy of timing of quartz timer

A timekeeping and timer technology, applied to electronic timers, devices for measuring time intervals, changing time indications, etc., can solve the problems of demanding crystal quality, cumbersome operation process, and high cost, and achieve lower quality requirements and less system Time error, the effect of accurate time display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

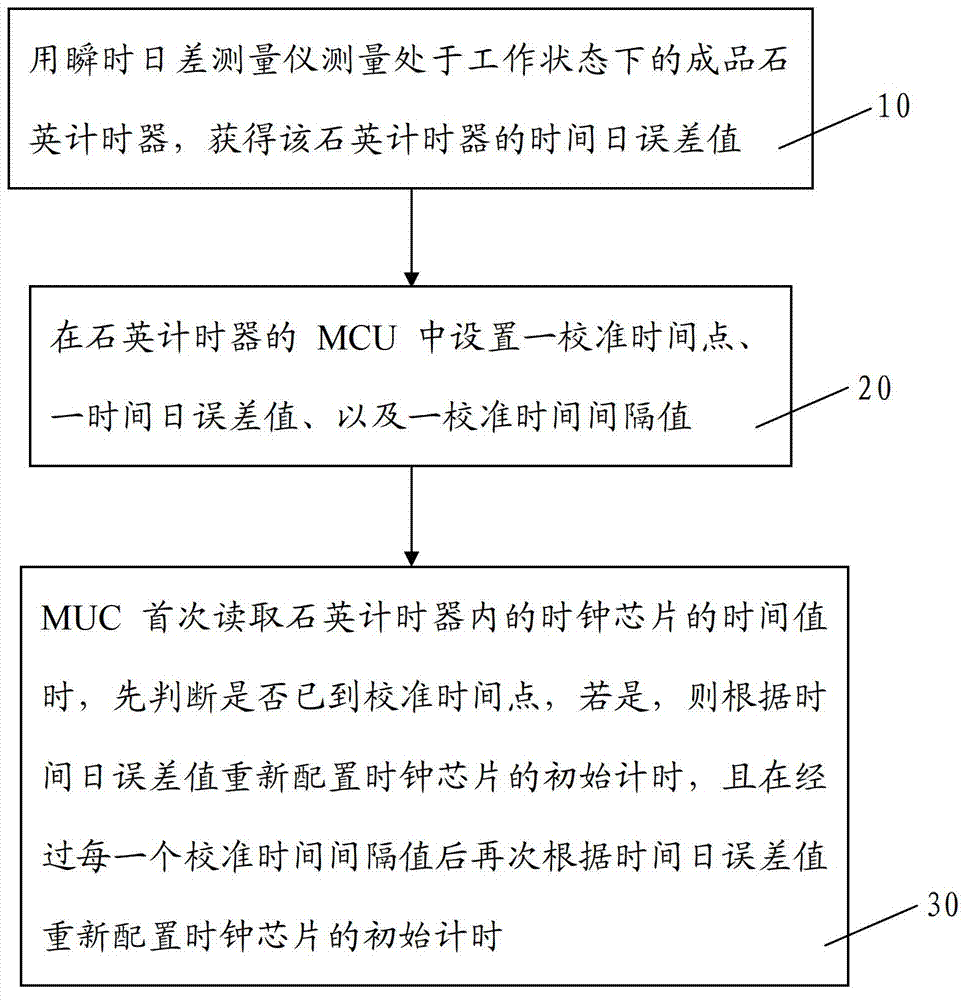

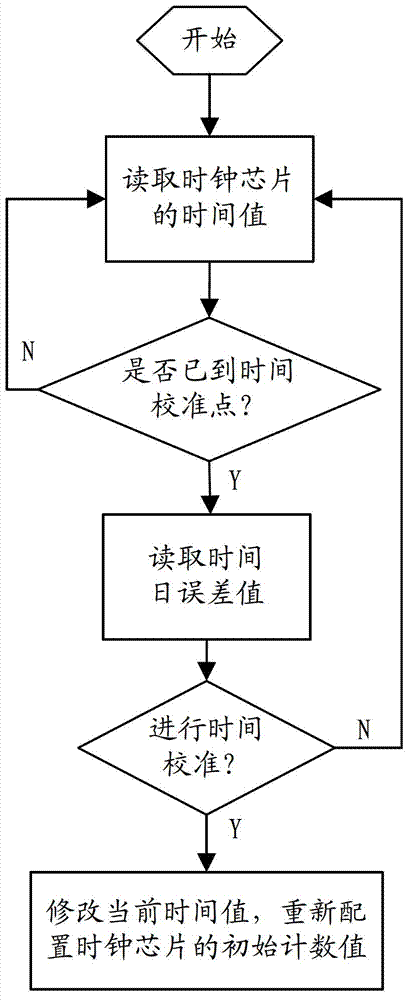

Method used

Image

Examples

Embodiment 1

[0027] For a finished temperature and humidity meter with a perpetual calendar function, the daily error value of the time is +0.92s measured with an instantaneous day difference meter; the correction value stored in the register is 0.92s; at the same time, the calibration time point is set to 23:59:59 Second;

[0028] The re-set calibration time interval value is 5 days or 120 hours, that is, the time of the clock chip is automatically corrected every 5 days. The corrected time value on the fifth day is 0.92*5=4.60s. The corrected value is rounded to keep two significant figures, then At 23:59:59 on the fifth day, the MCU will re-correct the initial count value of the clock chip, that is, add 4.6s to the time value displayed in the next second; after the next calibration time interval of 5 days, continue to perform automatic calibration.

[0029] Since the cumulative error of 5 days is 0.92*5=4.60s, the corrected time value on the 5th day is 0.9*5=4.6s, and the time error is ...

Embodiment 2

[0031] Take a finished quartz crystal timer as an example: the frequency deviation of the finished quartz crystal timer is 32kHz crystal oscillator with 1PPM, that is, the frequency error in the working environment Δf=(f*frequency deviation) / 10 6 =(32*10 3 *1) / 10 6 =32*10 -3 Hz, where f is the frequency of the crystal oscillator; then the daily error corresponding to the finished timer made of the crystal oscillator is ±(1*24*60*60) / 10 6 =±0.0864s, assuming that the crystal oscillator constitutes a finished timer with a positive error and the true value of the daily error is +0.0864s under the influence of external conditions, the resulting true annual error value is (+0.0864s)*365=+ 31.536s.

[0032] The finished quartz crystal timer is tested with an instantaneous solar difference meter with an accuracy better than 0.4PPM, and the measured daily error value is +0.09s; therefore, the annual error value that needs to be corrected is (+0.09s)*365=+32.85 s. The annual error...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com