Inner-cooling stepped drill

A step drill and flat-bottomed technology, used in repairing drills, drilling tool accessories, drilling/drilling equipment, etc., can solve the problems of tool breakage and easy wear, and achieve the effect of improving strength, reducing wear and saving use costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

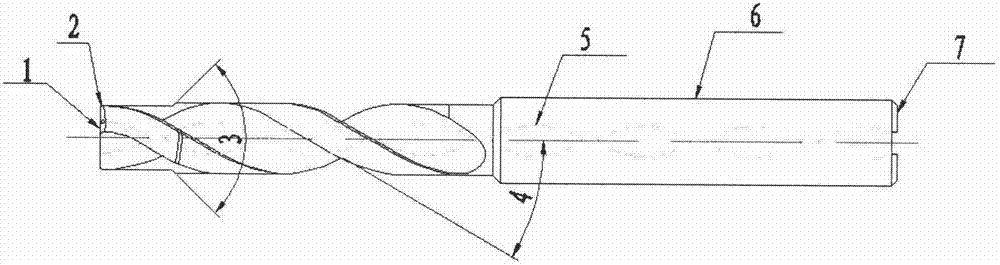

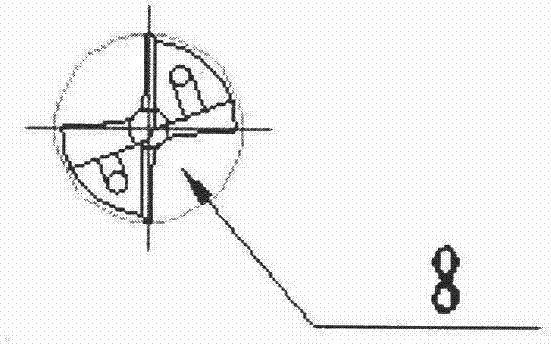

[0014] like figure 1 , 2 As shown, the inner-cooled step drill in this embodiment is processed by using a CNC five-axis linkage grinding machine and independently programming the tool program. The base material is made of cemented carbide, and the surface is provided with a TIALN coating. Specifically, the drill includes a shank 6 and a cutting edge 1, wherein the R angle part on the head 2 is conducive to uniform force on the drill, good impact resistance, and good heat dissipation. At the same time, it is chamfered and removed for the next process. The margin, the chamfer 3 is directly formed by the workpiece, and the helix angle 4 is 25°, the core thickness is relatively large, the drill has a better strength, and it is not easy to break when the diameter of the drill is relatively small.

[0015] During processing, inject cooling water into the drill bit through the water inlet hole 7 provided at the end of the shank, and the cooling water is drained from the drain hole 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com