Miniature heatproof moisture-proof welder

A welding machine and miniature technology, applied in welding equipment, arc welding equipment, cooling/ventilation/heating transformation, etc., can solve the problems of large heating value of winding, poor heat dissipation, short circuit of component pins or wiring, etc. The effects of dust accumulation on circuit boards, enhanced external ventilation and cooling, and reduced weight and volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] It will be further described below in conjunction with the drawings and embodiments.

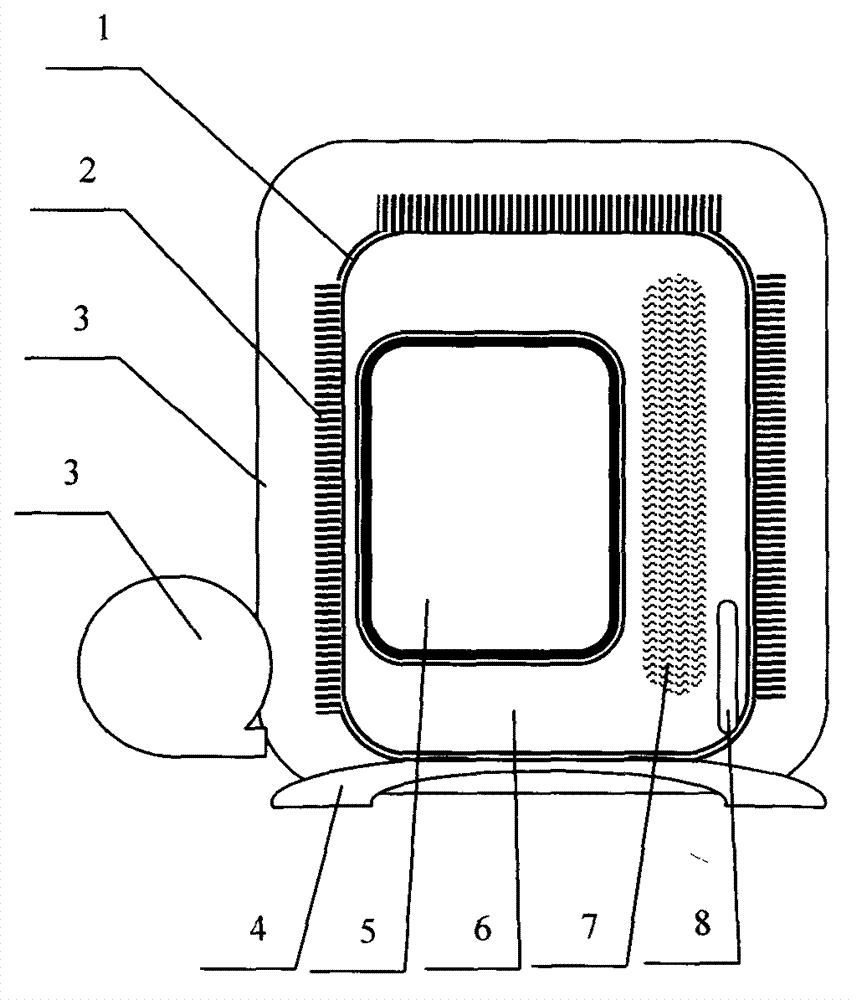

[0015] As attached figure 1 As shown, the welding machine core 6 is installed in the radiator 1, and at the same time, a sealed cavity 7 is formed in the inner gap of the installed core 6, and the thermally conductive insulating oil 8 is injected into the sealed cavity 7, and the radiator 1 is installed in the casing 3. Inside, at the same time, a fan 4 is connected to the casing 3, and the air outlet of the fan 4 is connected to the channel formed by the radiator 1 and the outer wall and the inner wall of the casing 3.

[0016] In the foregoing, the heat sink 1 has heat dissipation fins 2 on the outer wall or the inner wall. The heat sink 1 is made of aluminum and has good thermal conductivity.

[0017] In the foregoing, a temperature sensor 9 is installed in the radiator 1, and the fan 4 starts and stops according to the actual measurement value of the temperature sensor 9 and the preset...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com