Double-column hydraulic automobile elevator free of balancing of steel wire rope

A wire rope and lift technology, which is applied in the field of double-column hydraulic car lifts, can solve the problems of increased system cost, lifting imbalance, and hydraulic cylinder time difference, and achieve high synchronization stability, less maintenance, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

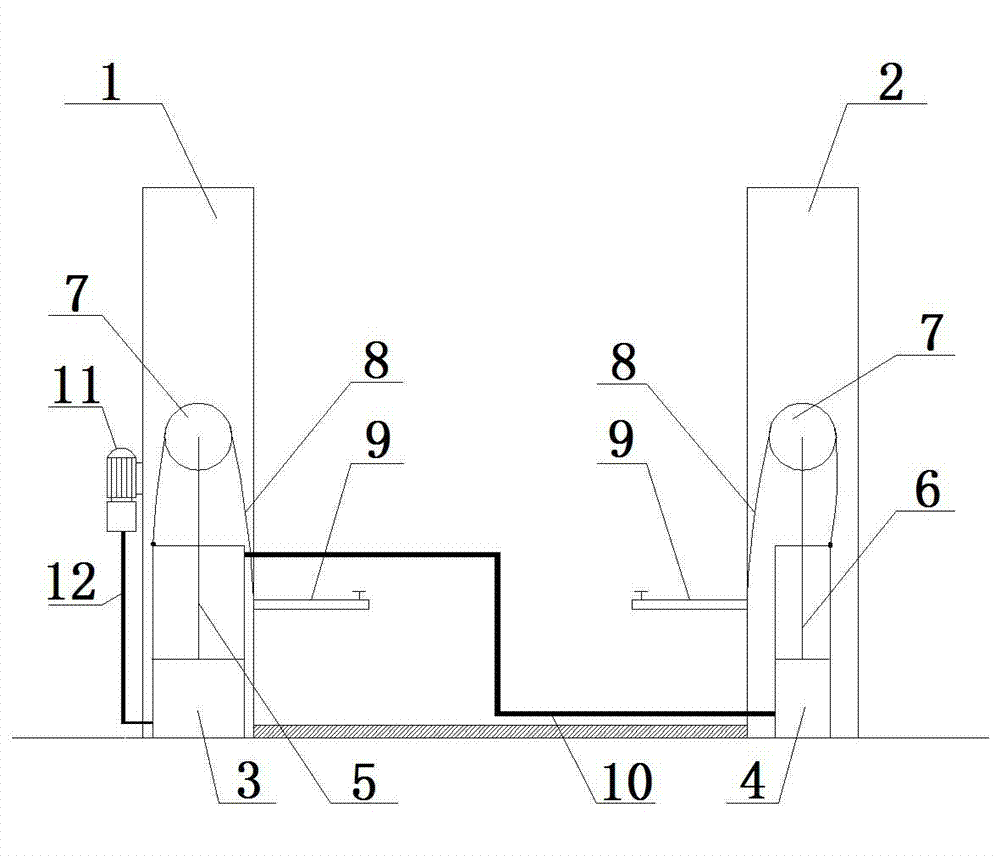

[0022] Embodiment one: if figure 1 Shown is a schematic diagram of the structure of a double-column hydraulic car lift without wire rope adjustment using a sprocket cylinder. The main body of the lift is the main column 1 and the auxiliary column 2 arranged on both sides. A double-acting main cylinder 3 and a single-acting auxiliary cylinder 4 are fixedly installed on the bottom of the auxiliary column 2, both cylinders are set forward, the rodless cavity of the main cylinder 3 communicates with the pump station 11 through the oil pipe 12, and the main cylinder 3 The rod chamber and the rodless chamber of the auxiliary oil cylinder 4 are connected in series through the oil pipe 10; a rotatable sprocket 7 is symmetrically arranged on the top of the piston rod 5 and the piston rod 6, and a chain 8 is arranged on the sprocket 7, and the chain 8 One end is fixed with the cylinder barrel of the oil cylinder, and its other end is fixed with the bracket 9, wherein the bracket 9 slide...

Embodiment 2

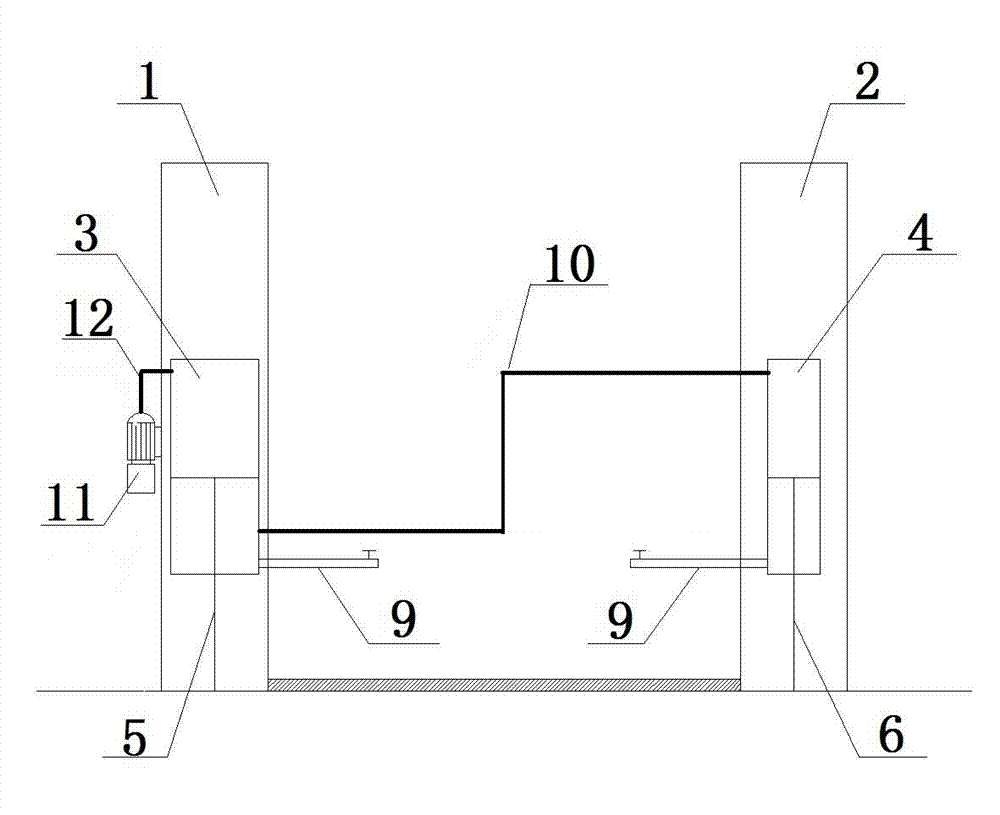

[0025] Embodiment two: if figure 2 Shown is a schematic diagram of the structure of the double-column hydraulic car lift without wire rope adjustment using an inverted oil cylinder. The main body of the lift is the main column 1 and the auxiliary column 2 arranged on both sides. The bottom of column 2 is fixed with double-acting main oil cylinder 3 and single-acting auxiliary oil cylinder 4. Both oil cylinders are inverted. It is fixed with the bottom plate of the auxiliary column 2; the bracket 9 is fixedly installed on the cylinder barrel of the main oil cylinder 3 and the cylinder barrel of the auxiliary oil cylinder 4 respectively, and the bracket 9 can lift up and down with the cylinder barrel; the main oil cylinder 3 The rodless chamber communicates with the pumping station 11 through an oil pipe 12 , and the rodless chamber of the main oil cylinder 3 and the rodless chamber of the auxiliary oil cylinder 4 are connected in series through an oil pipe 10 .

[0026] The i...

Embodiment 3

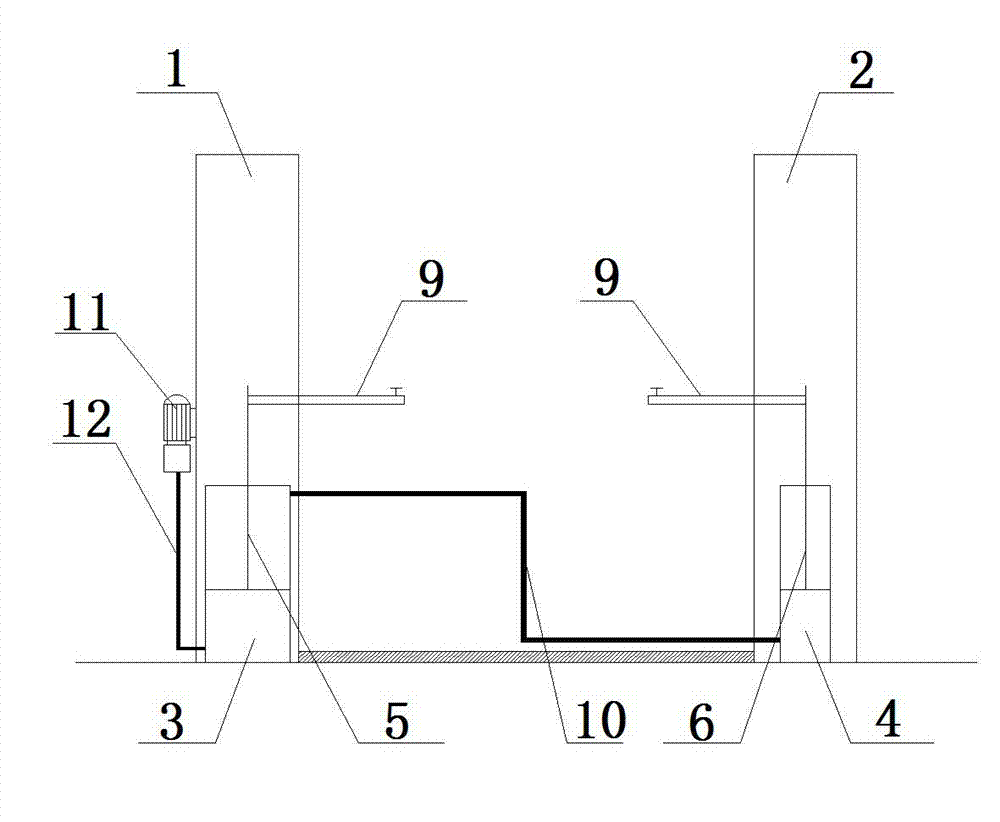

[0028] Embodiment three: as image 3 Shown is a schematic diagram of the structure of a double-column hydraulic car lift without wire rope adjustment using a straight-top oil cylinder. The main body of the lift is the main column 1 and the auxiliary column 2 arranged on both sides. A double-acting main cylinder 3 and a single-acting auxiliary cylinder 4 are fixedly installed on the bottom of the auxiliary column 2, both cylinders are set forward, the rodless cavity of the main cylinder 3 communicates with the pump station 11 through the oil pipe 12, and the main cylinder 3 The rod chamber and the rodless chamber of the auxiliary oil cylinder 4 are connected in series through the oil pipe 10; at the tops of the piston rods 5 and 6 of the main oil cylinder 3 and the auxiliary oil cylinder 4, a bracket 9 is fixedly installed, and the bracket 9 can be connected with the piston rods 5 and 6. Up and down lifting motion.

[0029] The initial state of the piston rod 5 on the main oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com