Critical extraction method for rotenone

A critical extraction and rotenone technology, applied in the production of bulk chemicals, organic chemistry, etc., can solve problems such as serious environmental hazards, and achieve the effects of avoiding soil compaction, high extraction rate, and high operational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

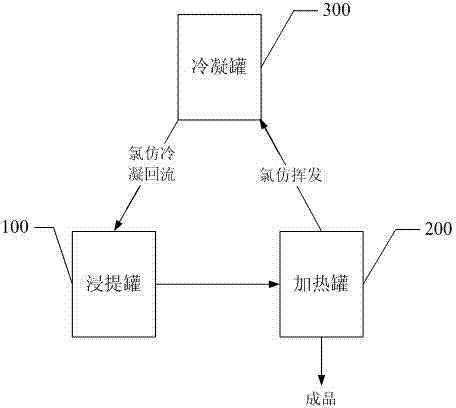

[0036] The method for critical extraction of rotenone in this embodiment includes crushing, extracting and concentrating the leaves of edamame; including the following extraction steps:

[0037] A, at first mass ratio is 0.5:6 the African bean leaf powder and the extraction solution are added in the extraction tank, and described extraction solution is by the N.N dimethylformamide and the chloroform that the mass ratio is 1:5 Composition; B. Then control the leaching temperature at 50°C and stir for 1 hour; C. Add the liquid in the leaching tank to the heating tank, raise the temperature to 62°C, chloroform volatilizes into the condensation tank, cools to liquid and then returns to the leaching tank. In the extraction tank; D, step A and step B are circulated for 4h, and the edamame leaf powder is extracted 4 times again; E, finally, the liquid in the heating tank is recovered to obtain the product. After testing, the extraction rate of rotenone Reached 87%.

[0038] The extr...

Embodiment 2

[0041] The method for critical extraction of rotenone in this embodiment includes crushing, extracting and concentrating the leaves of edamame; including the following extraction steps:

[0042] A, at first mass ratio is that 1:6 the African bean leaf powder and the extraction liquid join in the extraction tank, and described extraction liquid is by the N.N dimethylformamide and the chloroform that the mass ratio is 1:10 Composition; B. Then control the leaching temperature at 55°C and stir for 2 hours; C. Add the liquid in the leaching tank to the heating tank, raise the temperature to 68°C, chloroform volatilizes into the condensation tank, cools into a liquid, and then returns to the leaching tank. In the extraction tank; D, step A and step B are circulated for 5h, and the edamame leaf powder is extracted twice again; E, finally, the liquid in the heating tank is recovered to obtain the product. After testing, the extraction rate of rotenone Reach 90%.

[0043] The extract...

Embodiment 3

[0046] The critical extraction method of rotenone in this embodiment includes crushing, extracting and concentrating the leaves of Bean edamame; including the following extraction steps:

[0047] A, at first mass ratio is 1.5:6 the African bean leaf powder and the extraction solution are added in the extraction tank, and described extraction solution is by the N.N dimethylformamide and the chloroform that the mass ratio is 1:15 Composition; B. Then control the leaching temperature at 55°C and stir for 2 hours; C. Add the liquid in the leaching tank to the heating tank, raise the temperature to 65°C, chloroform volatilizes and enters the condensing tank, cools to a liquid and then returns to the leaching tank In the extraction tank; D, step A and step B are circulated for 5h, and the edamame leaf powder is extracted twice again; E, finally, the liquid in the heating tank is recovered to obtain the product. After testing, the extraction rate of rotenone Reach 90%.

[0048] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com