Preparation of polymer antibacterial nano-particles and magnetic antibacterial nano-particles containing halamine functional groups

A technology of antibacterial nanoparticles and halamine functionalization, which is applied in the field of preparation of polymer antibacterial nanoparticles and magnetic antibacterial nanoparticles, can solve the problems of complicated operation, cumbersome preparation methods, effective antibacterial ingredients (low content of halamine functional groups, etc.), and achieve The effect of broad-spectrum sterilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

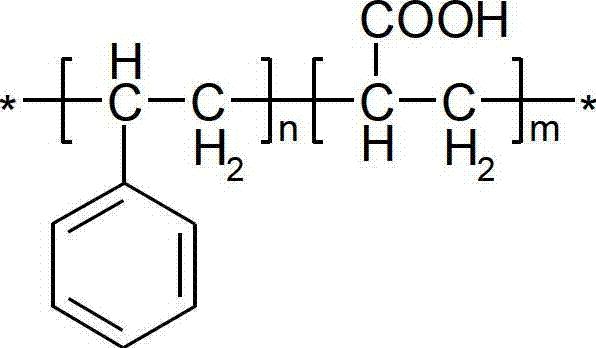

[0035] This example is the preparation of acrylic acid and styrene mixed polymer nanoparticles (n acrylic acid: n styrene = 1:0.7).

[0036] Take 58mL of secondary deionized water in a 100mL three-necked flask, then add 0.02mol (1.44g) of acrylic acid (AA), after the AA is dissolved, add 0.014mol (1.44g) of styrene (St), and stir for 10 minutes. Then add initiator potassium persulfate (K 2 S 2 o 8 )0.0001mol (0.027g), stirred and reacted at 80°C for 12 hours. Acrylic and styrene mixed polymer nanoparticles were obtained by centrifugation, washed with ethanol and water, and dried for later use.

Embodiment 2

[0038] This example is the preparation of acrylic acid and styrene mixed polymer nanoparticles (n acrylic acid: n styrene = 1:1.4).

[0039] Take 40mL of secondary deionized water in a 100mL three-necked flask, then add 0.01mol (0.72g) of acrylic acid (AA), after the AA is dissolved, add 0.014mol (1.44g) of styrene (St), and stir for 10 minutes. Then add initiator potassium persulfate (K 2 S 2 o 8 )0.0001mol (0.027g), stirred and reacted at 80°C for 12 hours. Acrylic and styrene mixed polymer nanoparticles were obtained by centrifugation, washed with ethanol and water, and dried for later use. 红外谱图分析数据:IR:3853.61、3820.93、3060.12、3026.14、2923.71、2361.17、1949.02、1869.32、1704.41、1601.10、1493.41、1452.59、1238.08、1069.77、1027.96、907.16、841.92、758.72、698.28、540.11cm-1 .

Embodiment 3

[0041] This example is the preparation of acrylic acid and styrene mixed polymer nanoparticles (n acrylic acid: n styrene = 1:2.1).

[0042] Take 29mL of secondary deionized water in a 100mL three-necked flask, then add 0.005mol (0.36g) of acrylic acid (AA), after the AA is dissolved, add 0.0105mol (1.08g) of styrene (St), and stir for 10 minutes. Then add initiator potassium persulfate (K 2 S 2 o 8 )0.0001mol (0.027g), stirred and reacted at 80°C for 12 hours. Acrylic and styrene mixed polymer nanoparticles were obtained by centrifugation, washed with ethanol and water, and dried for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com