Non-quenched and tempered steel applicable to piston rod of oil cylinder of bulldozer

A technology of non-quenched and tempered steel and bulldozer oil is applied in the field of material selection of hydraulic cylinder piston rod of construction machinery and material selection of piston rod of bulldozer oil cylinder, which can solve the problems of low production efficiency and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The invention is a non-quenched and tempered steel applied to bulldozer cylinder piston rods, which is composed of the following components in weight percentages: carbon 0.33%, silicon 0.36%, manganese 1.17%, alum 0.1%, sulfur 0.027%, phosphorus ≤ 0.0165% , molybdenum ≤ 0.011%, the balance is iron and a small amount of unavoidable impurities.

[0010] By adding Mn and V trace elements, the grains are refined and the mechanical properties of non-quenched and tempered steel are improved.

[0011] 1. Grain size

[0012] The benchmark requirement is 6.5 or above, and the actual test is 7.

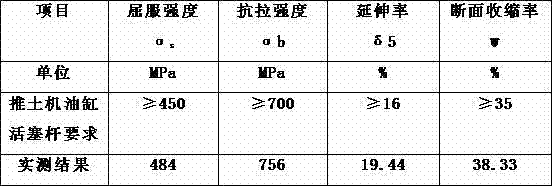

[0013] 3. Mechanical properties

[0014]

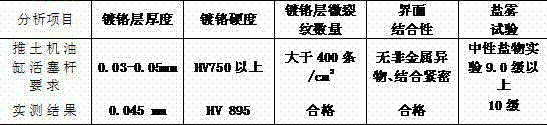

[0015] Analysis Project Intermediate frequency surface hardness IF Depth IF organization Bulldozer cylinder piston rod requirements 52∽60HRC 2∽3mm tempered martensite results of testing 55.27 HRC 2.0mm tempered martensite

[0016] Analysis Project UT flaw detection Penetration hardnes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com