Cold-formed thin-walled steel column and beam structural system for multistoried building

A technology of cold-formed thin-walled steel and beam-column structures, applied to truss structures, joists, girders, etc., can solve the problems of unfavorable bearing of horizontal wind loads and earthquakes, difficulty in fixing filling wall panels, and high construction accuracy requirements, etc. problem, achieve the effect of improving the shear bearing capacity of the wall, alleviating the effect of self-tapping screws, and fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

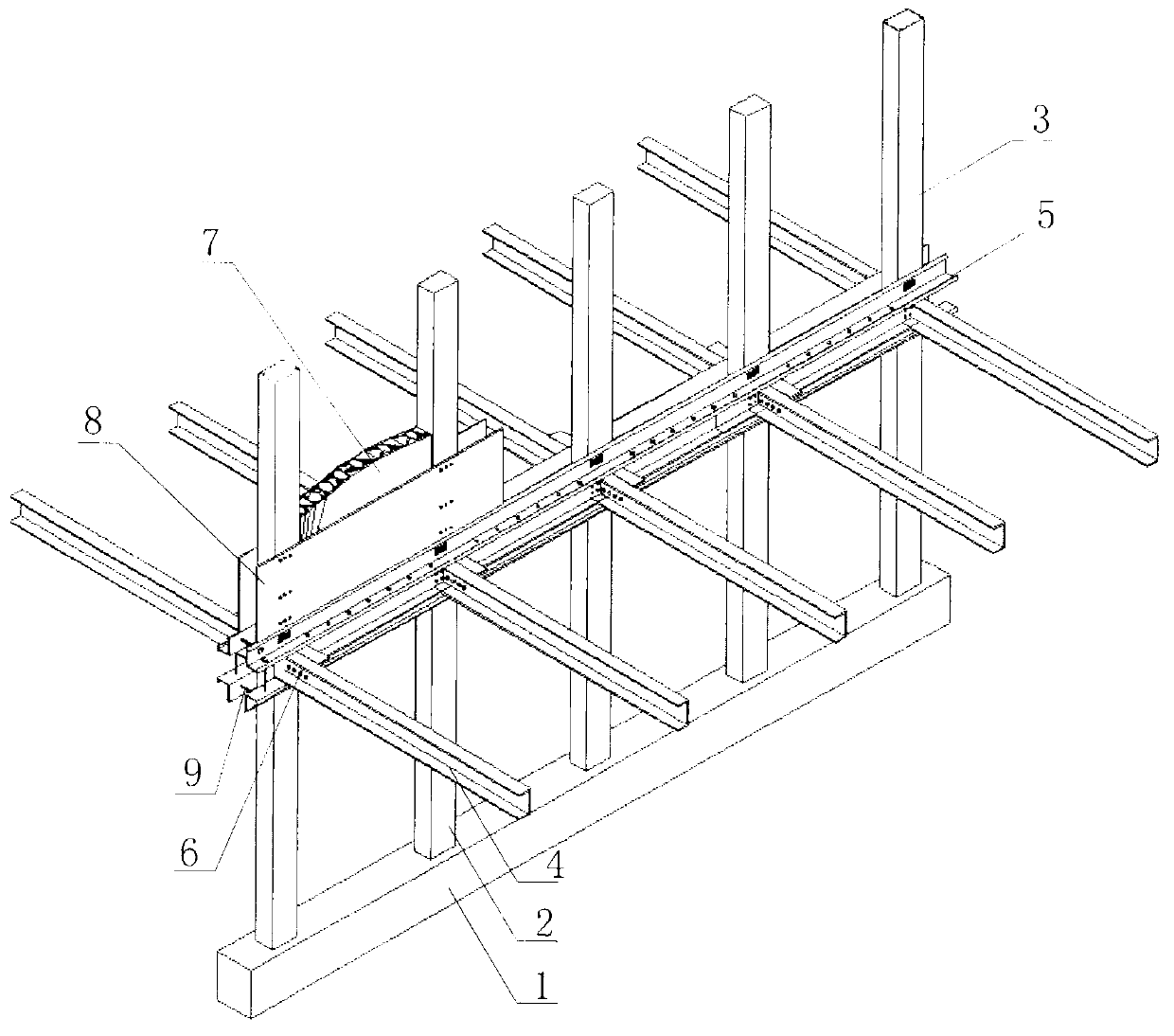

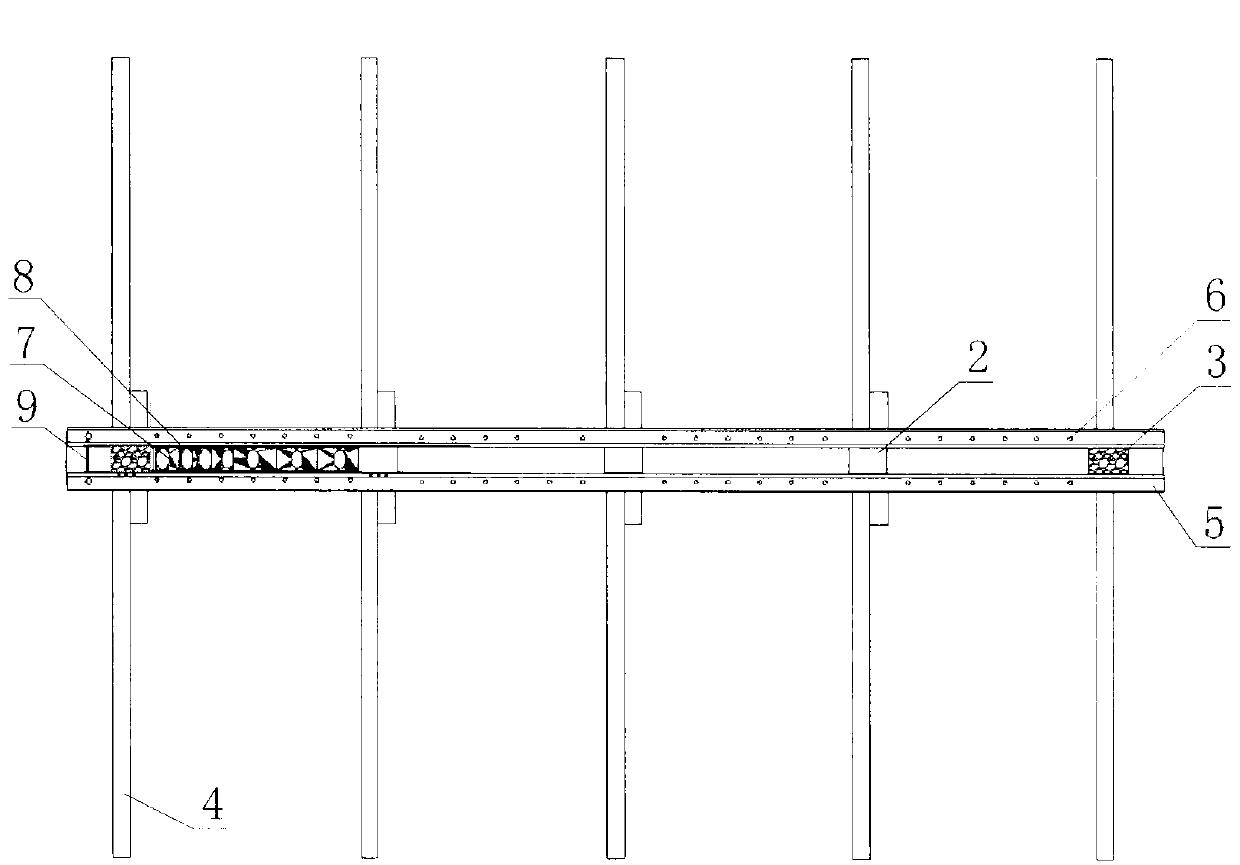

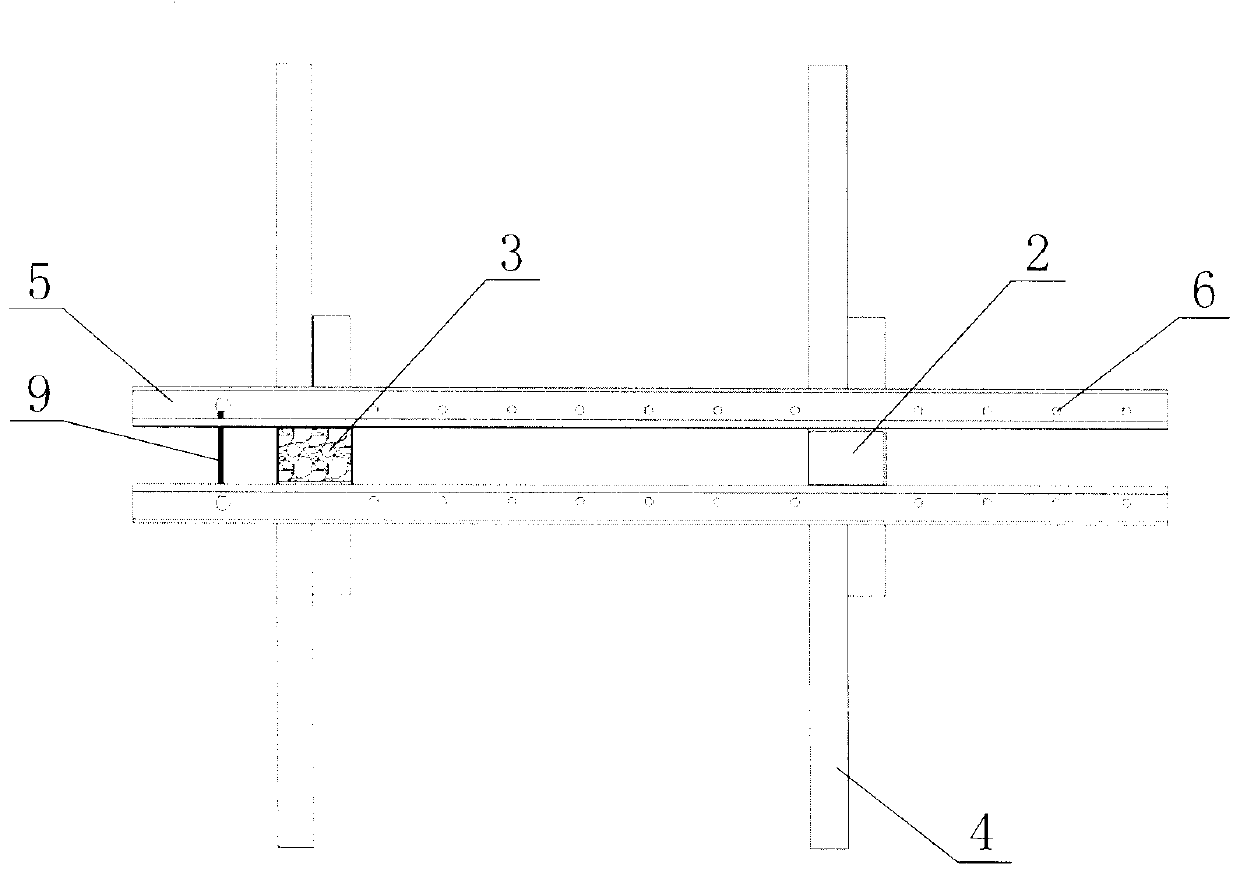

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

[0031] like Figure 1-Figure 5 , a cold-formed thin-walled steel beam-column structure system for a multi-storey house, comprising reinforced concrete ground beams 1, metal embedded parts are pre-embedded in the reinforced concrete ground beams 1, and the embedded parts are formed from the upper surface of the reinforced concrete ground beams 1 Outcrops, each outcrop is fixedly connected with an upright column, and each column is fixed with a beam perpendicular to the column at the designed height, and each beam is parallel to each other. It is characterized in that:

[0032] The column adopts rectangular steel pipe column 2;

[0033] The beam adopts the cold-formed thin-walled C-shaped steel beam 4 bent into an "L" shape, and forms the floor beam part, bending part and hook part;

[0034] The vertical part of the cold-formed thin-walled C-shaped steel beam 4 is a we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com