Special-shaped swing arm

A special-shaped rocker body technology, which is applied in the field of special-shaped rocker arms, can solve the problems that the rocker arm cannot use the valve mechanism, is heavy, and has low wear resistance, and achieves the effect of compact structure, small friction and wear, and low friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

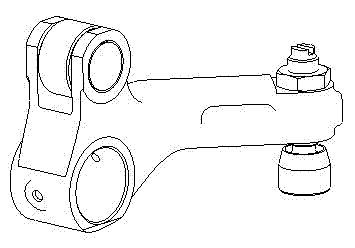

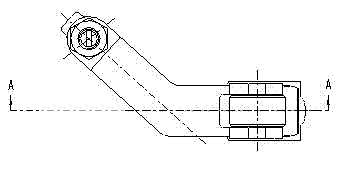

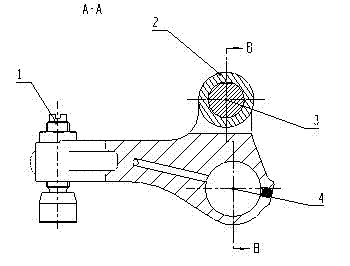

[0013] Such as figure 1 As shown, a special-shaped rocker arm is composed of a rocker body 4 and a rolling bearing. The rolling bearing is composed of a roller 2 and a rolling shaft 3. The roller 2 is correspondingly arranged on the rocker body 4. In the fork-shaped structure on both sides, the rolling shaft 3 is arranged in the roller 2, and the two ends of the rolling shaft are riveted together with the rocker body. The heterosexual rocker arm is made of aluminum alloy and has a T-shaped cross section. A universal ball head adjustment bolt 1 is used on the contact head of the rocker arm and the valve.

[0014] When the high-speed diesel engine gas distribution camshaft rotates, it drives the special-shaped rocker arm roller 2 to rotate and swing around the rocker shaft, the head of the special-shaped rocker arm descends, and the end surface of the universal ball head adjustment bolt 1 contacts the end surface of the valve stem and pushes the valve downward to open. At the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com