Ship simulating system and ship simulating method used during shipbuilding

A construction process and simulation system technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem that the actual production capacity of ships cannot be accurately evaluated, the site, facilities and equipment resources cannot be fully utilized, and the formulation of production plans Lack of reliable basis and other issues to achieve the effect of improving scientificity and effectiveness, innovation and optimization of production process, and standardized management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

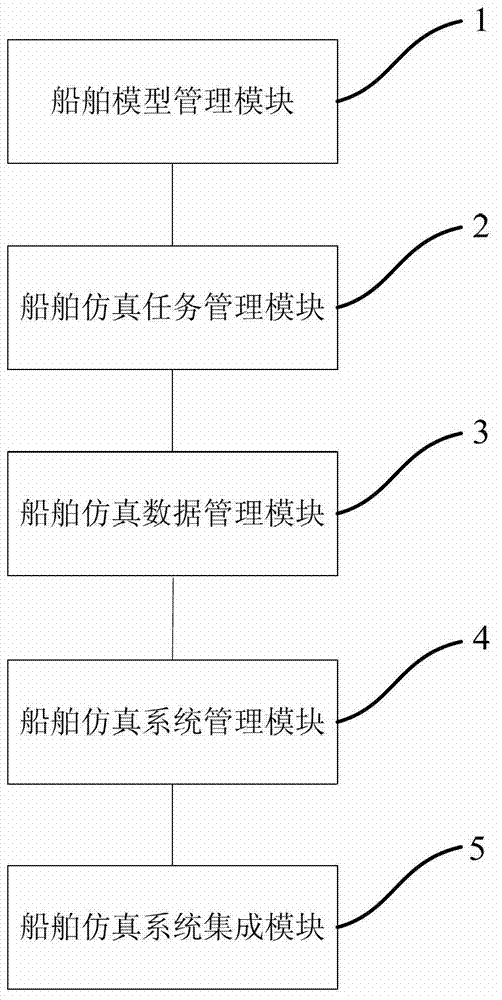

[0062] This embodiment provides a ship simulation system in the ship building process. The ship simulation system is as follows: figure 1 shown, including:

[0063] Ship simulation model management module 1, the ship simulation model management module 1 is used to add, update, delete ship simulation model, ship simulation model file, ship simulation mode, ship simulation stage, ship simulation equipment information. Wherein, the ship simulation model includes steel stockyard, cutting and processing, parts production, plane segmented assembly line, outdoor assembly and welding platform, indoor assembly and welding workshop, pre-outfitting, segmental painting, indoor berth, general assembly and berth The simulation model of 10 units such as loading and 3 global simulation models of the manufacturing stage, the general assembly and loading stage, and the whole process of ship construction.

[0064] The ship simulation task management module 2 is connected with the ship simulatio...

Embodiment 2

[0070] This embodiment provides a ship simulation method in the ship building process, which is applied in a ship simulation system, such as Figure 5 As shown, the ship simulation method includes:

[0071] S1. Input ship simulation products, processes, resources, and plan data in the ship construction process, that is, sort out the construction process and basic data of each operation unit of ship construction, and compile the modeling reference book for each operation unit of ship construction. in. Input product data, that is, input the 3D model of the hull and outfitting parts and related attributes; input process data, that is, define the shipbuilding process, and sort out the logistics logic and scheduling logic within each operation unit and between units; input resource data, That is to input resource models and data of facilities, equipment, sites, and personnel involved in the ship construction process; input planning data, that is, input planning data such as the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com