Production method of self-adhesive electromagnetic wire

A production method and electromagnetic wire technology, applied in the manufacture of circuits, electrical components, cables/conductors, etc., can solve the problems of increased product quality control, large energy consumption, etc., and achieve the effects of improving competitiveness and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

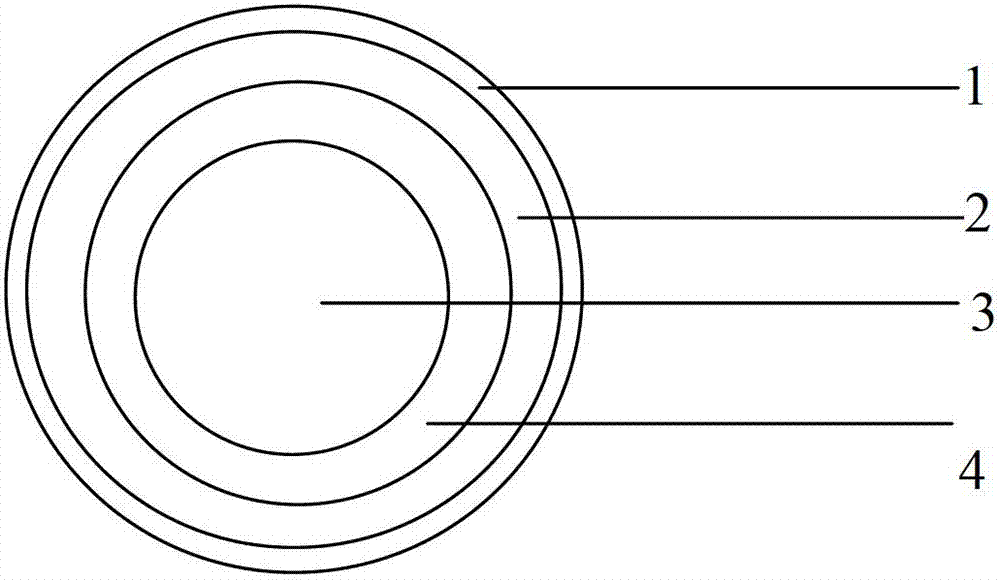

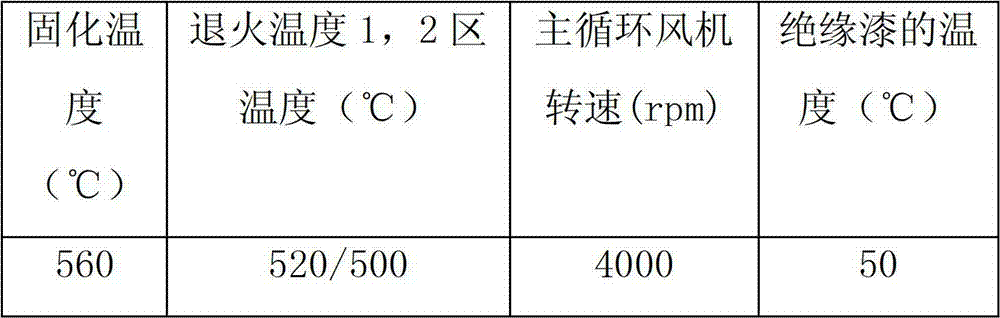

[0025] The production method of the self-adhesive magnet wire of the present invention will be described in conjunction with the accompanying drawings and examples.

[0026] In order to produce self-adhesive magnet wires for compressor motors, a long-term exploration was carried out in the selection of raw materials and production processes. After multiple rounds of PDCA cycle screening, the best manufacturing process was selected.

[0027] The production method of self-adhesive magnet wire of the present invention, this method comprises the following steps:

[0028] 1) Selection of raw materials:

[0029] The main raw material of the self-adhesive magnet wire is copper rod, the copper rod uses low-oxygen copper with a purity of more than 99%, and the insulating varnish coated uses imported polyesterimide (PEI) paint and polyamideimide (PAI) Paint, self-adhesive insulating paint;

[0030] 2) Production process of self-adhesive magnet wire:

[0031] ①Pull

[0032] Firstly, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com