Inner-cooling transformer rolling iron core

A technology of wound iron core and transformer, which is applied in the field of wound iron core transformer and three-dimensional transformer wound iron core structure, which can solve the problems of unsatisfactory cooling effect, difficult temperature reduction, easy deformation of iron core, etc. Heat dissipation effect, overcoming the difficulty of cooling, and eliminating the effect of the hottest point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Figure 1-7 It is a figure which shows each embodiment of the inner cooling type transformer wound core of this invention. The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but this does not constitute any limitation to the present invention.

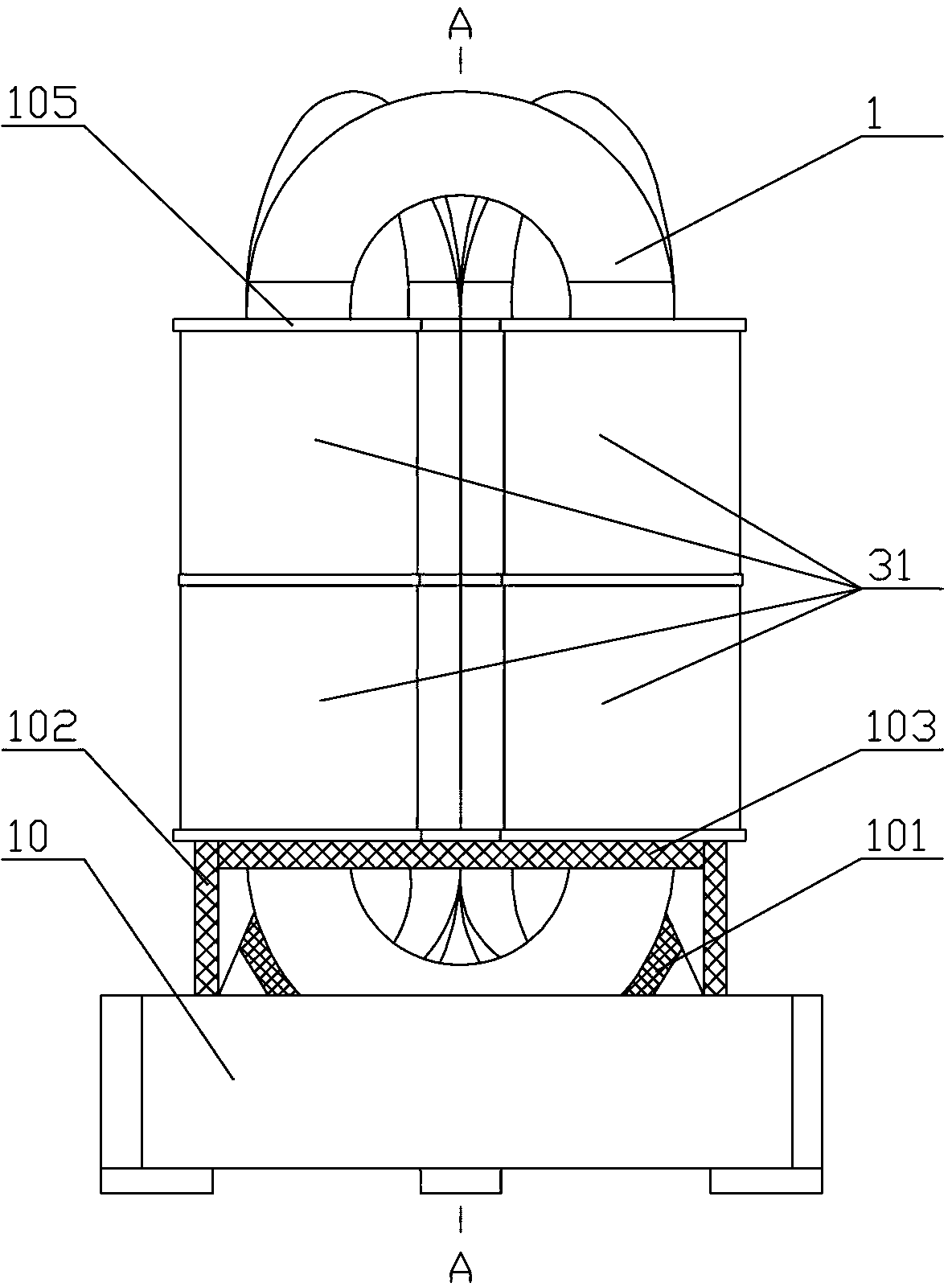

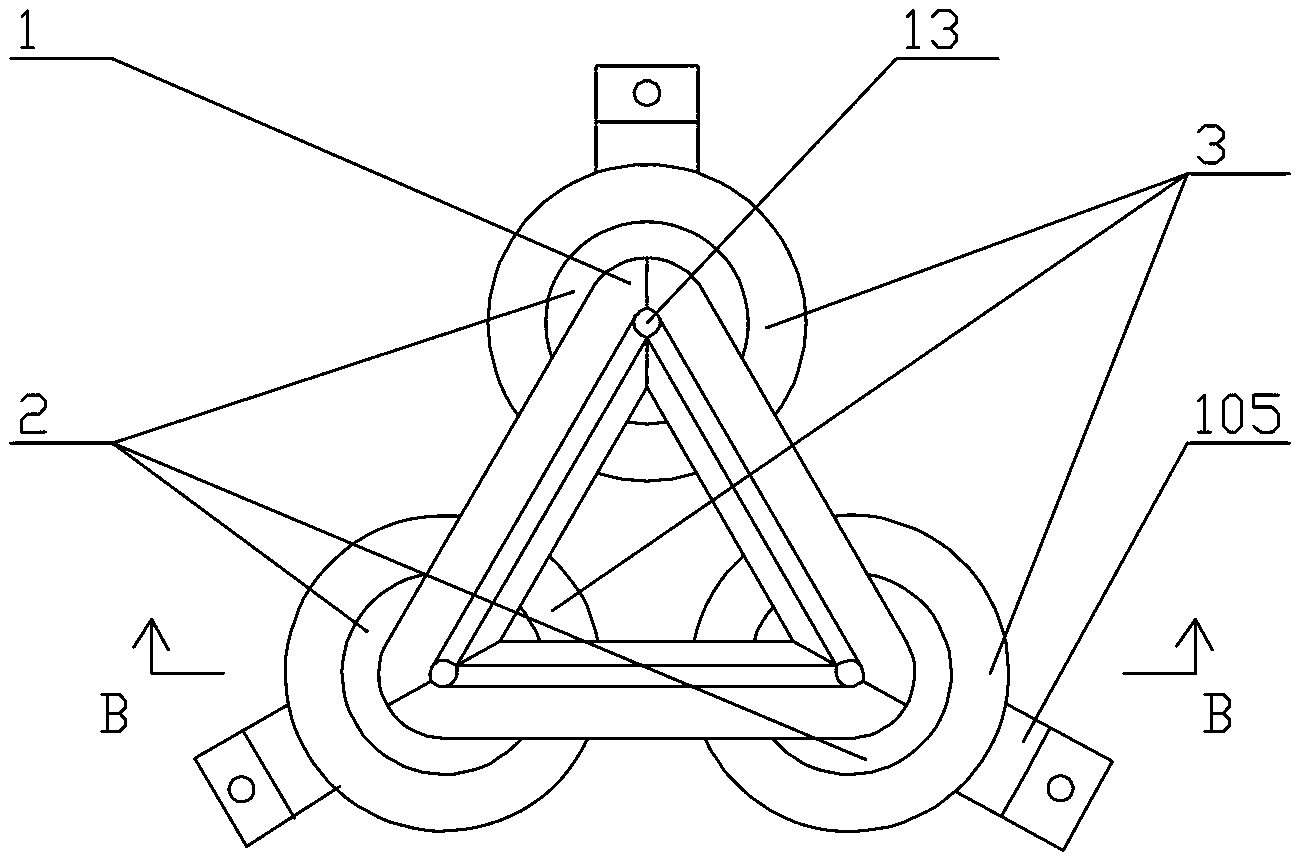

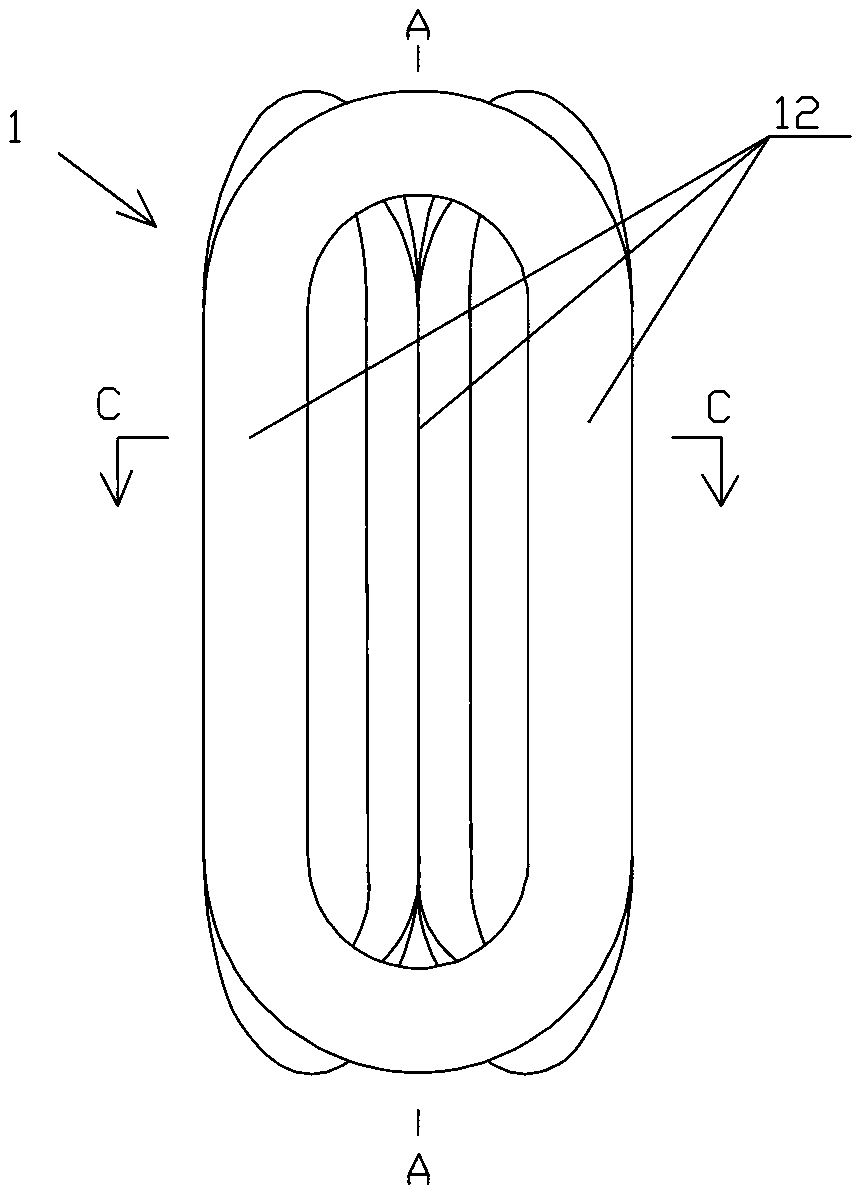

[0022] figure 1 It is a partial structural schematic diagram of an embodiment of an inner-cooled transformer wound core of the present invention, figure 2 yes figure 1 , which shows the overall appearance structure of the inner-cooled three-dimensional wound iron core 1 fitted with low-voltage and high-voltage windings. see Figure 1 to Figure 2 , the novel inner-cooled three-dimensional wound iron core power transformer of the present invention comprises a three-dimensional wound iron core 1 of a three-phase three-column three-dimensional structure, and its three identical iron core columns 12 have such figure 1 As shown in the paralle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com