High-color-rendering high-power LED (light emitting diode) encapsulation structure and manufacture method of high-color-rendering high-power LED encapsulation structure

An LED packaging, high-power technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of poor heat conduction and heat dissipation, inability to adjust the light angle, and reduce the speed of heat dissipation, and achieve excellent heat conduction and heat dissipation. Heat dissipation performance improvement, the effect of improving heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

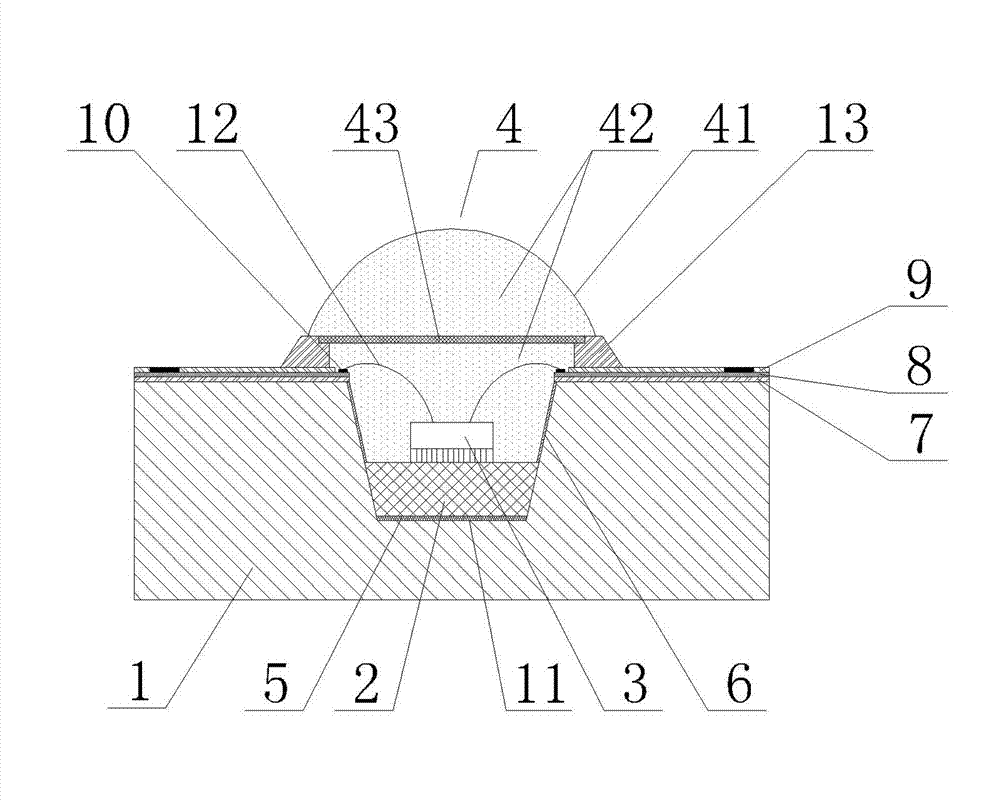

[0025] Such as figure 1As shown, the high color rendering index high-power LED packaging structure of the present invention includes a high thermal conductivity substrate 1, a high heat dissipation material block 2, a high-power LED chip 3 and a package assembly 4, wherein the high thermal conductivity substrate 1 is provided with Blind hole 11, the high heat dissipation material block 2 is installed in the blind hole 11 and bonded with the high thermal conductivity substrate 1 through the high thermal conductivity adhesive 5, and the high power LED chip 3 is attached to the high heat dissipation material block 2 on. Wherein, the blind hole 11 provided on the above-mentioned high thermal conductivity substrate 1 is an inverted trapezoid, the bottom surface and the side surface of the inverted trapezoid blind hole 11 are flat and smooth, and the shape of the above-mentioned high heat dissipation material block 2 is the lower half of the inverted trapezoid blind hole 11. It is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com