Brushless direct current motor electronic speed governor based on STM32

An electronic governor and circuit technology, applied in the field of model aircraft, can solve problems such as unfavorable governor expansion, larger space occupied by hardware, and weak anti-interference ability, so as to improve control performance, use function, stability and The effect of improving real-time performance and enhancing anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

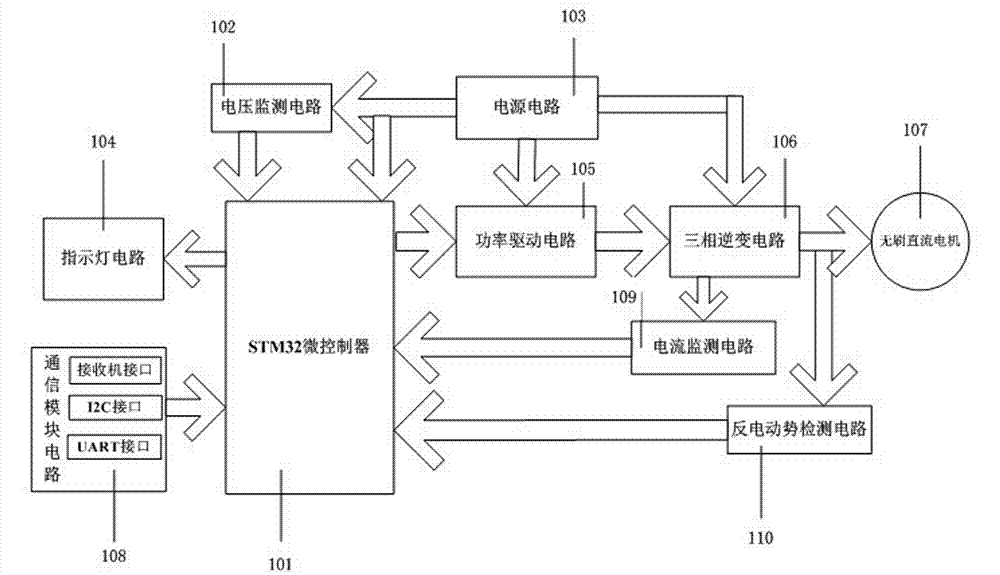

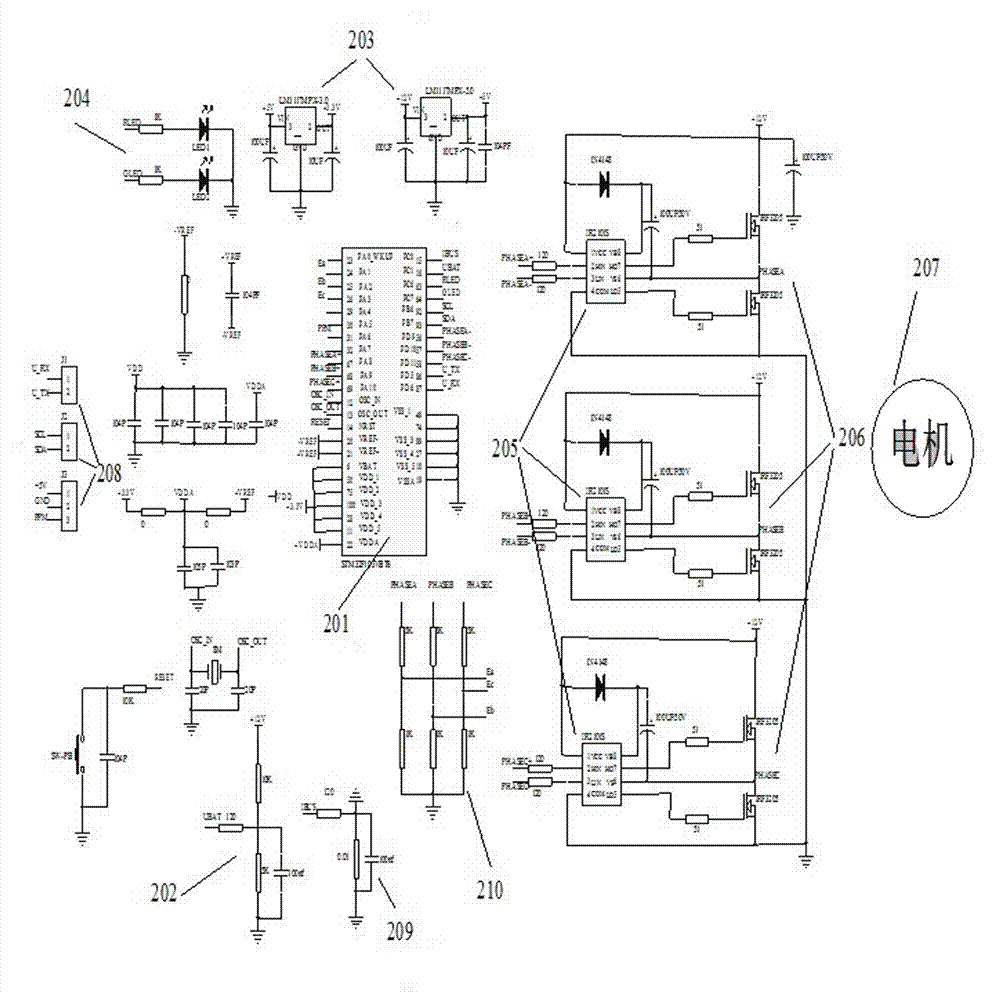

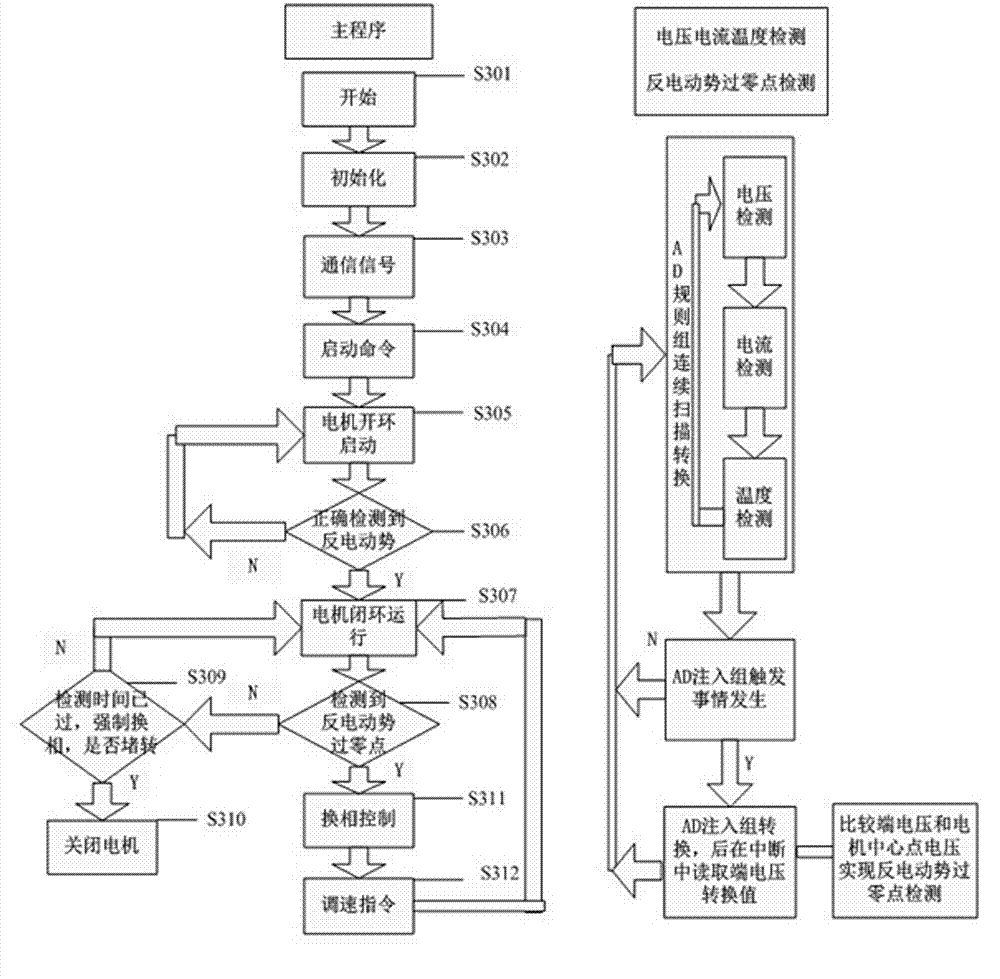

[0019] according to figure 1 Shown is a schematic structural diagram of an embodiment of the present invention, which consists of an STM32 microcontroller 101, a power drive circuit 105, a three-phase inverter circuit 106, a voltage monitoring circuit 102, a current monitoring circuit 109, a communication module circuit 108, and a counter electromotive force detection circuit 110. Composed of indicator light circuit 104 and power supply circuit 103, STM32 microcontroller 101 is connected to communication module circuit 108, power drive circuit 105, counter electromotive force detection circuit 110, voltage monitoring circuit 102, current monitoring circuit 109 and indicator light circuit 104 respectively , the three-phase inverter circuit 106 is connected with the power drive circuit 105 and the brushless DC motor 107, and the power circuit 103 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com