Sounding device and manufacturing method thereof

A technology for a sound-emitting device and a manufacturing method, applied in the electro-acoustic field, can solve the problems of difficulty in ensuring the consistency of the thickness of the diaphragm and other properties, difficulty in ensuring the consistency of the thickness of the diaphragms of each layer, and inability to meet the working needs of the sound-emitting device. Good performance, simplified process, high product stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

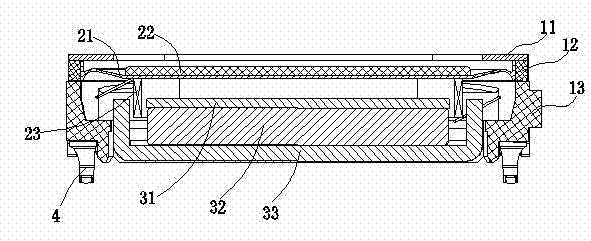

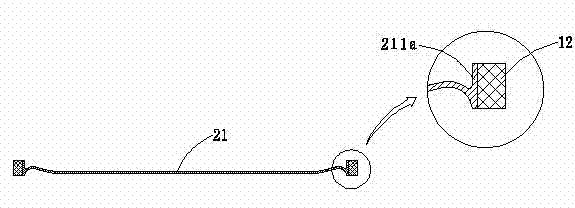

[0025] Embodiment one: if figure 1 As shown, the sound generating device of the present invention includes a vibration system, a magnetic circuit system, and a peripheral frame for accommodating the fixed vibration system and the magnetic circuit system. Wherein the vibration system includes a diaphragm assembly and a voice coil 23 combined with the lower side of the diaphragm assembly; the diaphragm assembly includes a diaphragm 21 and a plastic support 12 combined with the edge of the diaphragm 21; in order to improve the high-frequency characteristics of the diaphragm 21, A rigid composite layer 22 is bonded to the upper surface at the center of the diaphragm 21 . The magnetic circuit system includes a washer 31, a magnet 32 and a basin frame 33 combined from top to bottom. The magnetic circuit system forms a magnetic gap for accommodating the voice coil 23. After the voice coil 23 is connected to an electric signal, it receives an ampere force in the magnetic circuit sys...

Embodiment 2

[0034] Embodiment two: Figure 4It is a cross-sectional view of the diaphragm assembly of the sound-generating device in Embodiment 2 of the present invention. As shown in the figure, compared with Embodiment 1, the present invention also has a second combination with the support 12 injection-molded on the lower side of the support 12. part 211b, the second joint part 211b further increases the joint area between the edge of the diaphragm 21 and the support member 12, thereby increasing the firmness of the bond between the silicone rubber diaphragm 21 and the support member 12. In addition, the second bonding portion 211b is not limited to the structure that is injection-molded and bonded to the lower side of the support member 12, and can also be injection-molded and bonded to the upper side thereof, which can increase the bonding area between the diaphragm 21 and the support member 12 and improve the firmness of the bond. degree.

[0035] The steps of the manufacturing meth...

Embodiment 3

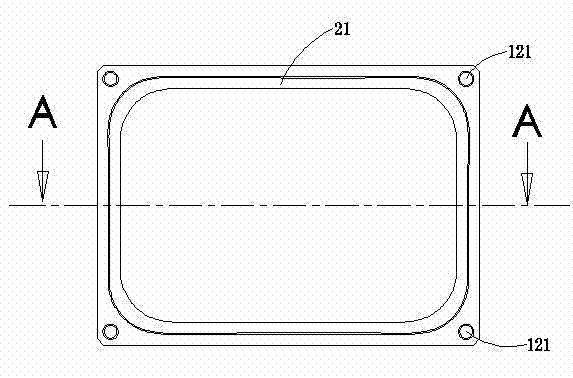

[0037] Embodiment three: as Figure 5 with Image 6 As shown, in this embodiment, the edge of the silicone rubber diaphragm 21 is provided with a first bonding portion 211a that is injection-molded with the inner side wall of the support 12, and a second bond that is injection-molded with both the lower side and the upper side of the support 12. part 211a and the second joint part 211c, this structure further increases the area where the silicone rubber diaphragm 21 and the support member 12 are injection-molded, and improves the firmness of the bond between the diaphragm 21 and the support member 12 . It should be noted that the positioning hole 121 cannot be covered during the injection molding process of the second combining portion 211 a and the second combining portion 211 c with the support member 12 , so as to facilitate the positioning of the diaphragm assembly in subsequent processes.

[0038] The manufacturing process of the sound-generating device in this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com