Compound acidity regulator for silage and use method thereof

An acidity regulator and silage technology, applied in the preservation method of animal feed raw materials, animal feed, application and other directions, can solve the problems of shortening the silage period, accelerating the silage acidification process, poor fermentation, etc. effect, the effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

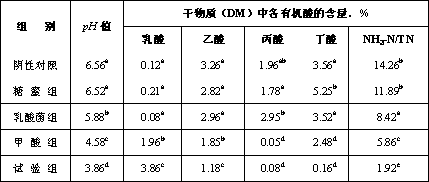

[0037] This experimental example is to implement the influence of a compound acidity regulator for silage on the fermentation quality of alfalfa silage and the influence of aerobic stability. The composition and weight ratio of the compound acidity regulator for silage are 60% propionic acid, 10% formic acid and 30% sodium benzoate. According to the composition and weight ratio of the above-mentioned raw materials provided by the present invention, the propionic acid is first accurately weighed and put into a stainless steel 316L reactor. 0 Slowly and evenly put sodium benzoate under the condition of C and the rotating shaft speed of the reactor at 200rpm, after fully dissolving and chemically reacting for 1-1.5h, add formic acid, continue dissolving, chemically react for 0.5-1h until the mixed solution becomes a homogeneous clear solution, That is, the compound acidity regulator product for silage of the present invention is obtained.

[0038] In this experiment, the alfalfa...

Embodiment 2

[0083] The composition and weight percentage of the compound acidity regulator for silage of the present invention are 65% of propionic acid, 30% of sodium benzoate and 5% of formic acid.

[0084] The physicochemical characteristics of the composite acidity regulator for silage that embodiment 1 and embodiment 2 make are: a. the density range is 1.05-1.16g / cm 3 ; b. pH The range is 3.2-3.5; c. 1% aqueous solution pH 3.5 + 0.2; 0.5% aqueous solution pH 3.6 + 0.2.

Embodiment 3

[0086] The composition and percentage by weight of compound acidity regulator for silage of the present invention are propionic acid 50%, sodium benzoate 25%, water 25%, and the physicochemical characteristic of the composite acidity regulator for silage obtained is: a. Density range is 1.02 -1.15g / cm 3 ; b. pH The range is 4.1-4.5; c.1% aqueous solution pH 4.0 + 0.2; 0.5% aqueous solution pH 3.5 + 0.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com