Aromatized composite particle filter stick and production method thereof

A technology of filter rods and solid particles, which is applied in the fields of e-liquid filter elements, applications, tobacco, etc., can solve the problems of reducing the taste of tobacco, achieve the effects of enriching cigarette aroma, high adsorption capacity, and modifying the state and concentration of smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

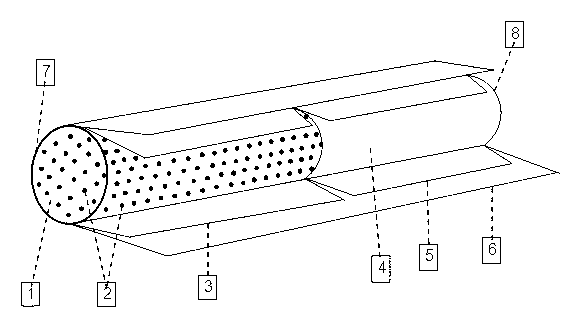

Image

Examples

Embodiment 1

[0035] S1. Granulation: Grind the star anise, cinnamon and fennel, pass through a 20-mesh sieve, and mix according to the mass ratio of star anise powder: cinnamon powder: fennel powder = 1:0.5:1 to obtain fragrant solid particles.

[0036] S2. Dispersion: according to the proportion of flavor solid particles accounting for 5% of the mass of the acetate fiber, the solid particles are evenly dispersed on the acetate tow for ordinary tobacco after opening (commercially available), to obtain the tow containing composite particles;

[0037] S3. Molding: the composite particle filter rod is prepared by wrapping the solid particle tow with composite particle filter rod forming paper.

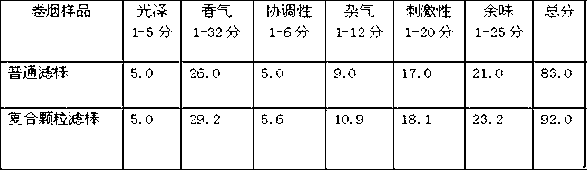

[0038] The smoke analysis of the filter sticks using the method of GB / T19609-2004 (using conventional analysis, smoking machine to measure tar) shows that cigarettes with flavored solid particle filter sticks are more effective than cigarettes with acetate tow filter sticks for ordinary cigarettes...

Embodiment 2

[0048] S1. Granulation: Grind the star anise, cinnamon and fennel, pass through a 20-mesh sieve, and mix according to the mass ratio of star anise powder: cinnamon powder: fennel powder = 1:0.5:1 to obtain fragrant solid particles.

[0049] S2. Flavoring treatment: mix peppermint oil and cumin oil at a mass ratio of 1:1 as the food flavor of this example, and add flavor to the solid particles described in S1 at an amount of 0.1% of the total mass of the flavor solid particles ,well mixed;

[0050] S3. Balance: put the solid particles obtained in S2 into a constant temperature and humidity box to balance the moisture for 48 hours, so that the moisture content is about 10%;

[0051] S4 Dispersion: Uniformly disperse the solid particles on the acetate tow (commercially available) for common cigarettes after opening according to the ratio of the solid particles after the equilibrium moisture to 5% of the mass of the acetate fiber, to obtain the tow containing composit...

Embodiment 3

[0063] S1. Granulation: Grind cinnamon and cloves separately, pass through a 40-mesh sieve, and mix according to the mass ratio of 1:1 to obtain solid particles of flavoring materials.

[0064] S2. Flavoring treatment: mix peppermint oil and fennel oil in a mass ratio of 1:3 as the food essence of this example, add it to the solid particles of flavor obtained in S1 at a ratio of 0.08% of the total mass of solid particles of flavor, and mix uniform;

[0065] S3. Balance: put the solid particles obtained in S2 into a constant temperature and humidity box to balance the moisture for 48 hours, so that the moisture content is about 10%;

[0066] S4. Dispersion: uniformly disperse the solid particles on the acetate tow for ordinary tobacco (commercially available) after opening according to the ratio of the solid particles after the equilibrium moisture to 5% of the mass of the acetate fiber, to obtain the tow containing composite particles;

[0067] S5. Forming: the composite part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com