Device and process for effectively removing sulfur trioxide in smoke through natural alkali

A technology of sulfur trioxide and trona, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of low utilization rate, poor development and utilization conditions, weak industrial foundation, etc., and achieve optimal adjustment and reduction. The effect of flue resistance and pressure loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

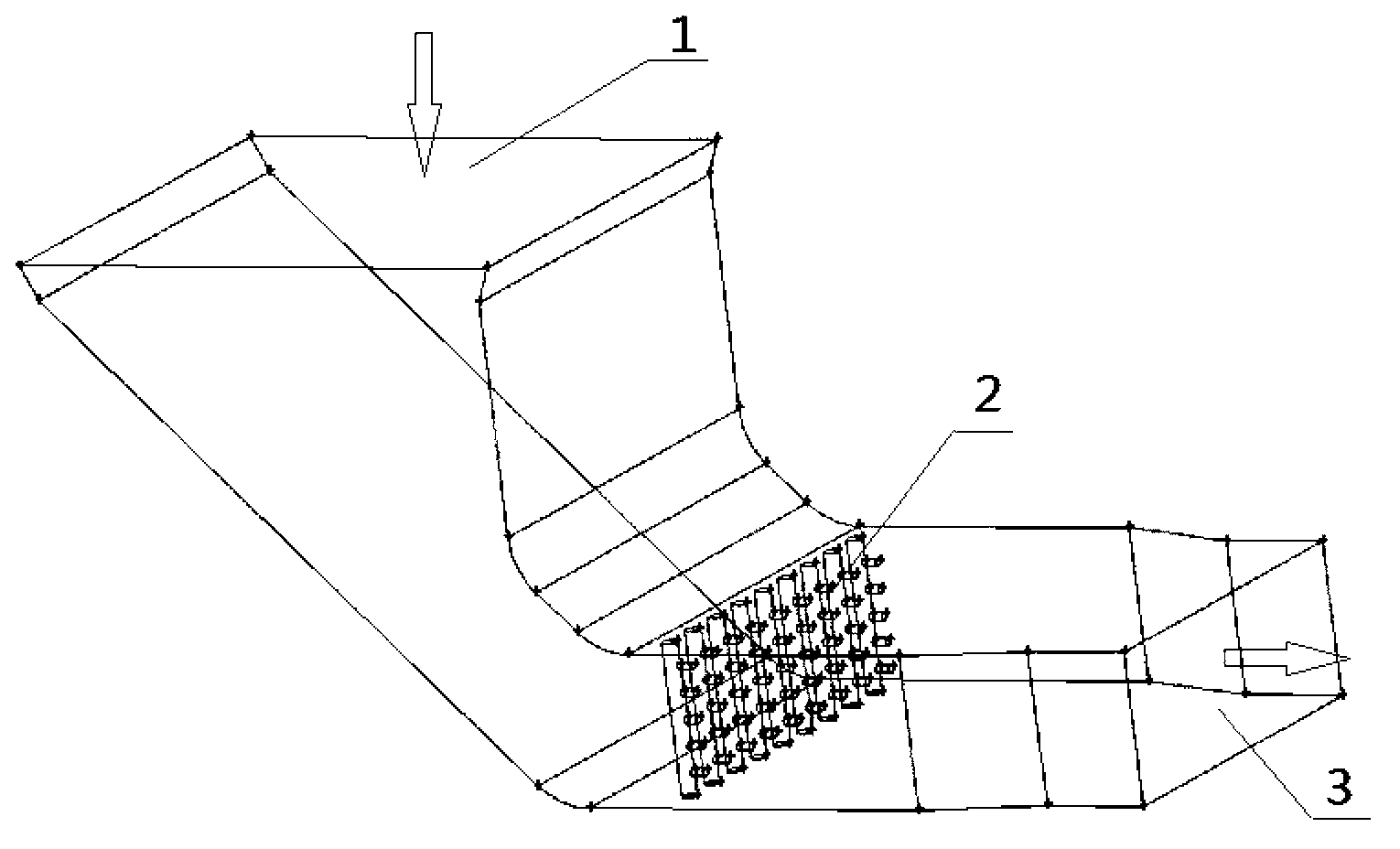

[0022] Taking a certain 300WM coal-fired unit as an example below, the present invention will be further described in conjunction with the accompanying drawings.

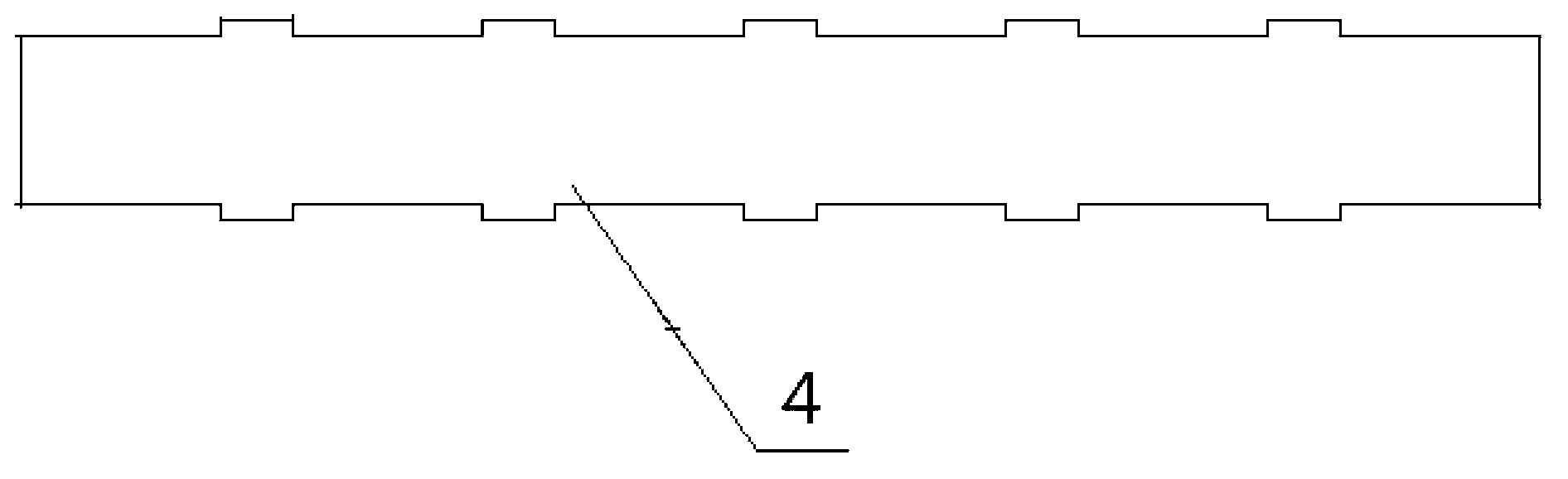

[0023] A device for effectively removing sulfur trioxide from flue gas by using trona, including a flue gas inlet 1 and a flue gas outlet 3, between the flue gas inlet 1 and the flue gas outlet 3 there is a curved transitional flue, the curved transitional flue A nozzle system 2 is provided inside, and an anti-wear plate 4 is arranged in the direction of flue gas flow of the nozzle system 2, and the nozzle system 2 is connected to a trona slurry preparation system.

[0024] According to flue gas SO 3 Trona content, composition of trona and actual operation of the boiler 3 , 50%Na 2 CO 3 ) with SO 3 The molar ratio is about 9:1, in order to ensure the removal of SO by semi-dry method 3 while improving the SO 3 removal rate.

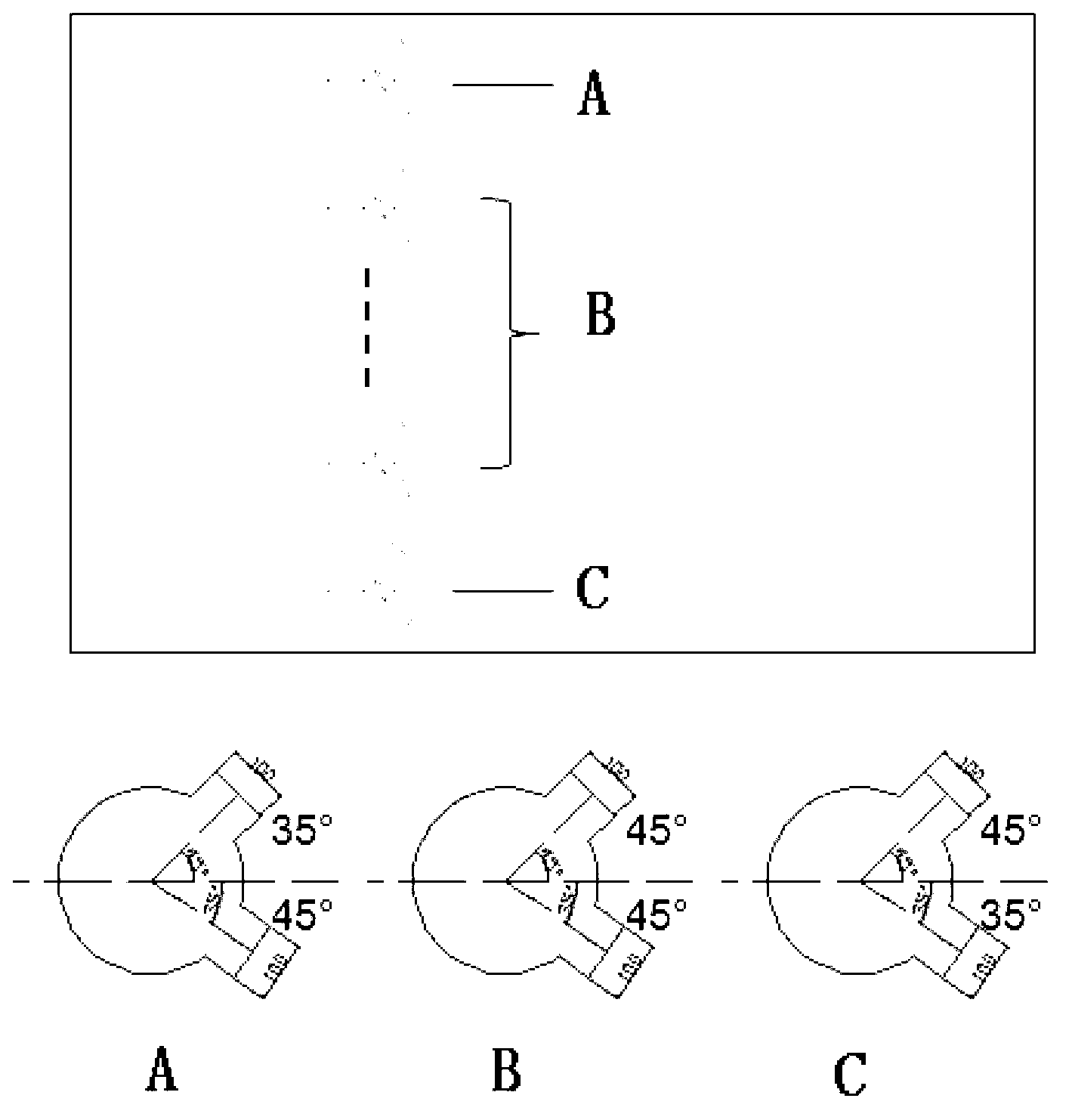

[0025] The nozzle system is arranged in the flue between the tail of the SCR reactor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com