Batch-type high shear emulsifying machine

A high-shear emulsifier, intermittent technology, applied in the field of intermittent high-shear emulsifiers, can solve the problems of not being able to obtain the emulsified state, not being able to change the stirring force and temperature, and affecting the emulsification effect, and achieve good practical value , good emulsifying effect and high emulsifying rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

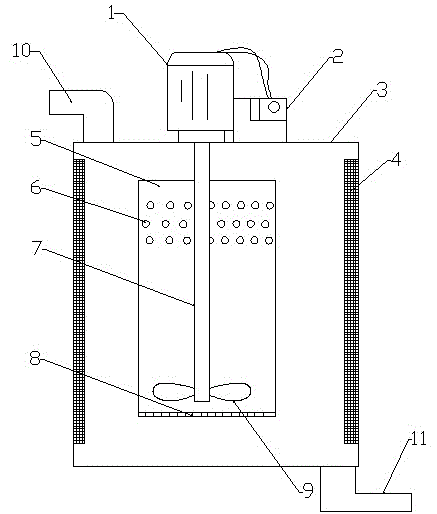

[0015] Specific implementation methods: such as figure 1 As shown, a kind of intermittent high-shear emulsifier includes a barrel-shaped tank body 3, a motor 1 is arranged above the tank body 3, and the motor 1 drives an emulsifier in the tank body 3. The inner wall of the tank body 3 An electric heating device 4 is provided on it. The tank body 3 is provided with a built-in diversion inner cylinder 5, the top of the inner cylinder 5 is sealed, and a plurality of diversion holes 6 are uniformly arranged on the upper barrel wall; the bottom mouth of the diversion inner cylinder 5 is fixedly installed with An emulsifying shear net 8; a stirring shaft 7 is arranged in the middle of the diversion inner cylinder 5, and the stirring shaft 7 is connected with the motor 1 above the tank through a coupling; the free end of the stirring shaft 7 is equipped with a stirring paddle 9. A feed port 10 is provided on the side wall of the tank body 3 , and a discharge port 11 is provided at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com