Method for preparing butadiene from C4 aliphatic hydrocarbons by oxidative dehydrogenation and catalyst used by same

An oxidative dehydrogenation and catalyst technology, which is applied in the chemical industry, can solve the problems of no test result data for catalytic performance, unstable performance, rising cost, etc., and achieve the effect of simple structure, high activity and selectivity, and ample conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

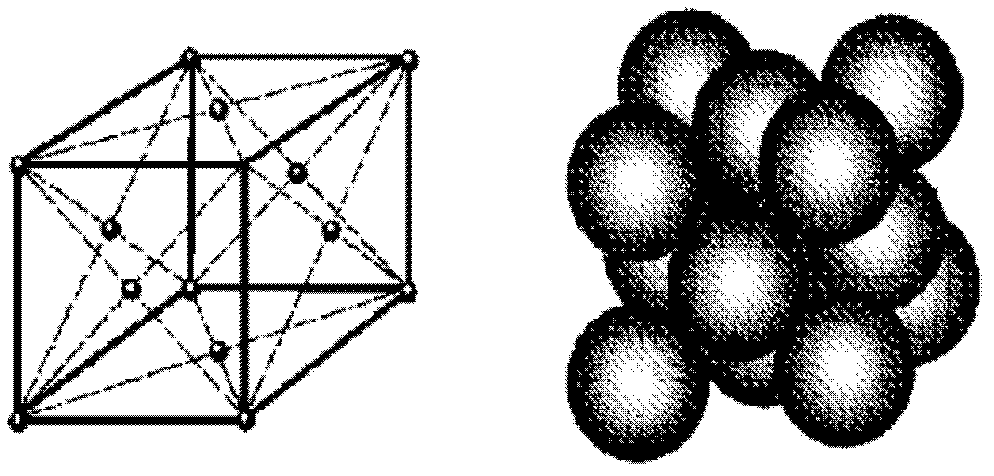

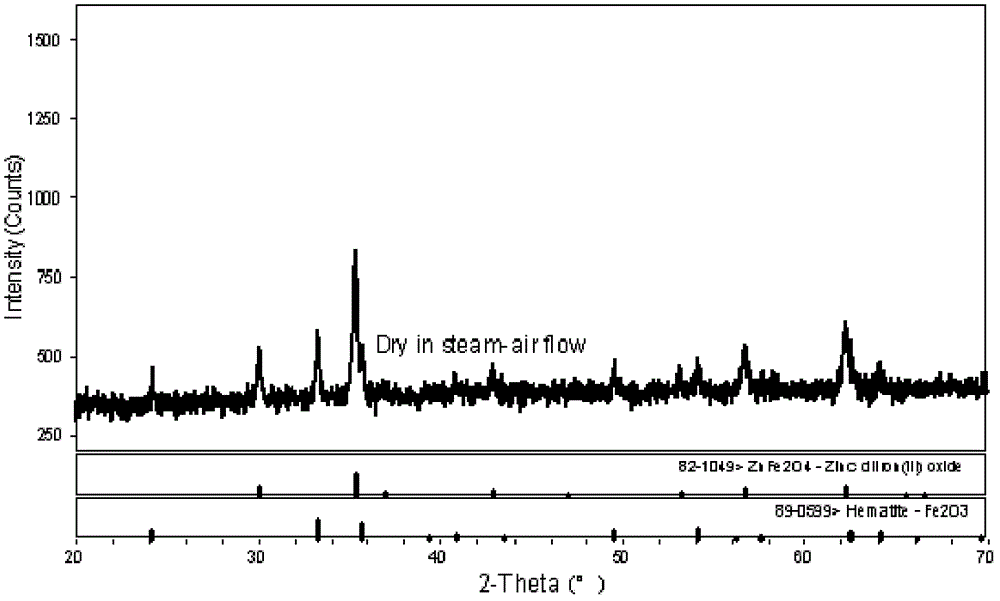

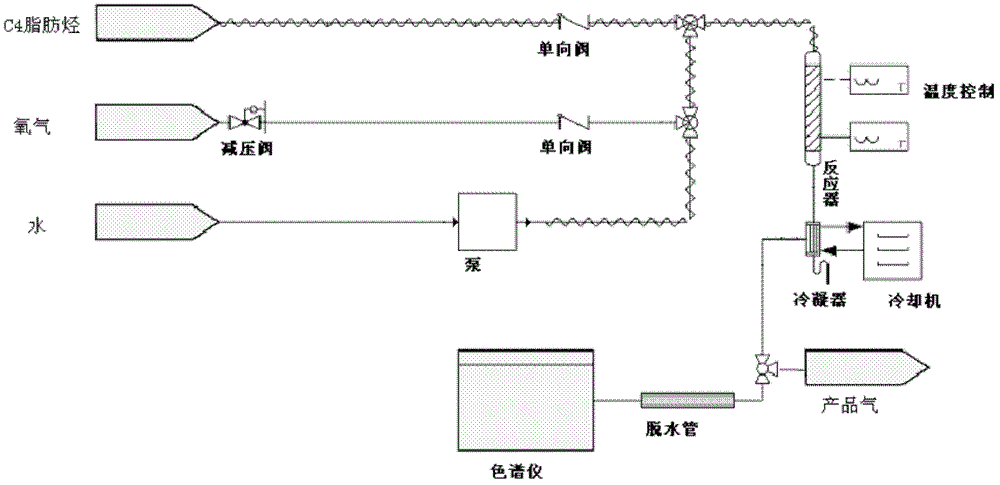

[0029] C4 aliphatic hydrocarbon space velocity 400h -1 , the catalyst bed temperature is 406°C, the vapor-ene ratio is 12, the oxygen-ene ratio is 0.6, and the catalyst is ZnFe-containing 2 o 4 65%, α-Fe 2 o 3 35%, the reaction results are shown in Table 1.

[0030] Table 1 Reaction Results

[0031]

Embodiment 2

[0033] C4 aliphatic hydrocarbon space velocity 400h -1 , the catalyst bed temperature is 404°C, the vapor-ene ratio is 12, the oxygen-ene ratio is 0.8, and the catalyst is ZnFe-containing 2 o 4 65%, α-Fe 2 o 3 35%, the reaction results are shown in Table 2.

[0034] Table 2 Reaction Results

[0035]

Embodiment 3

[0037] C4 aliphatic hydrocarbon space velocity 400h -1 , the catalyst bed temperature is 387°C, the vapor-ene ratio is 9, the oxygen-ene ratio is 0.6, and the catalyst is ZnFe-containing 2 o 4 65%, α-Fe 2 o 3 35%, the reaction results are shown in Table 3.

[0038] Table 3 Reaction Results

[0039]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap