Red jujube automatic classification system and classification method

An automatic grading and jujube technology, which is applied in sorting and other directions, can solve problems such as hindering the large-scale development of enterprises, not meeting food hygiene requirements, and low grading accuracy, and achieves the effect of simple structure, strong practicability, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

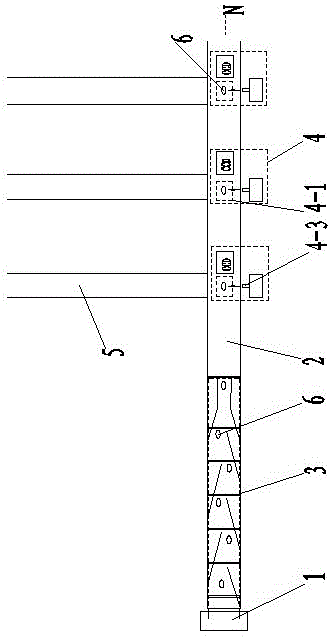

[0016] like figure 1 As shown, a jujube automatic grading system includes a vibrating feeder 1, a conveyor belt 2 on the transmission mechanism, a finished product packaging line 5, and also includes a guiding and sorting mechanism 3 and a grading detection actuator 4. The conveyor belt 2 is a transparent conveyor belt; the conveyor belt One end of the conveyor belt 2 is provided with a vibrating feeder 1, and one end of the conveyor belt 2 is provided with a positive sorting mechanism 3, and a certain amount of gap is set between the positive sorting mechanism 3 and the conveyor belt 2, and several finished product packages are arranged at intervals at the other end of the conveyor belt 2. Line 5, several product packaging lines 5 and the conveyor belt 2 are in a right-angle shape, and a classification detection actuator 4 is arranged above the conveyor belt 2 at the junction of each finished product packaging line 5 and the conveyor belt 2.

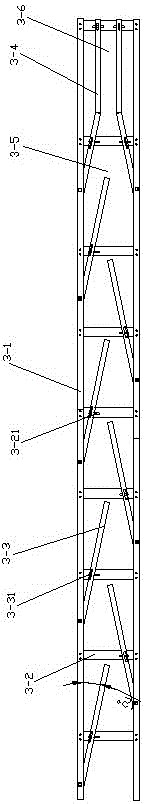

[0017] like figure 2 , 3 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com