Laminated NiAl material and preparation method thereof

A layered and laminated technology, applied in the direction of metal layered products, chemical instruments and methods, lamination, etc., can solve problems such as the difficulty of NiAl-based alloy plates, and achieve overcoming essential brittleness, simple production process, and easy industrial production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

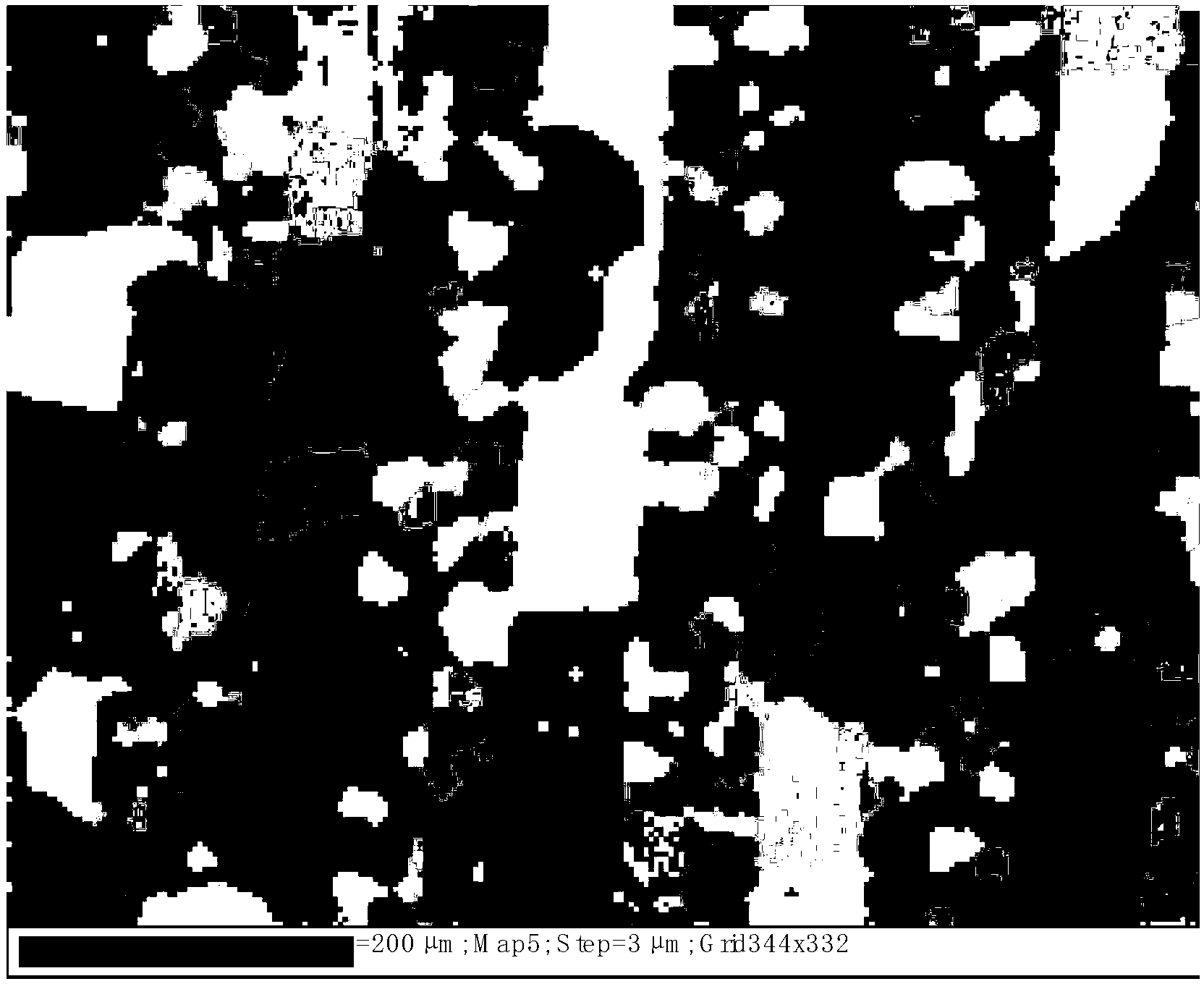

[0014] Embodiment 1: This embodiment is a layered NiAl material, which is prepared by alternate lamination of Ni foil and Al foil, and the crystal grains of the layered NiAl material are distributed in layers.

[0015] The crystal grains described in this embodiment have a great influence on the high-temperature mechanical properties of metal materials due to the grain size. When the temperature is high, the coarse-grained alloy has a higher creep limit and durable strength limit, and the layered NiAl material grains are distributed in layers, which has the advantages of fine-grained materials and coarse-grained materials at room temperature and high temperature. Its unique layered structure endows it with good mechanical properties.

[0016] The advantages of this embodiment: 1. In the preparation method of a layered NiAl material in this embodiment, a layered NiAl material with a layered distribution of grain size is obtained by laminating Ni foil and Al foil and then perfor...

specific Embodiment approach 2

[0017] Embodiment 2: The difference between this embodiment and Embodiment 1 is that: the thickness of the Ni foil is 0.05mm-0.5mm; the thickness of the Al foil is 0.05mm-0.5mm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0018] Specific embodiment 3: The difference between this embodiment and specific embodiments 1 or 2 is that: after Ni foil and Al foil are alternately laminated, both the upper surface and the lower surface are Ni foil. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com