High-precision offset printing method

An offset printing, high-precision technology, applied in printing, printing devices, etc., can solve the problems of difficult digestion and absorption of implementation process technology, outflow of high-quality and fine-printed business, and the overall effect is not very ideal, so as to enhance the sense of realism, purchase Easy, accurate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

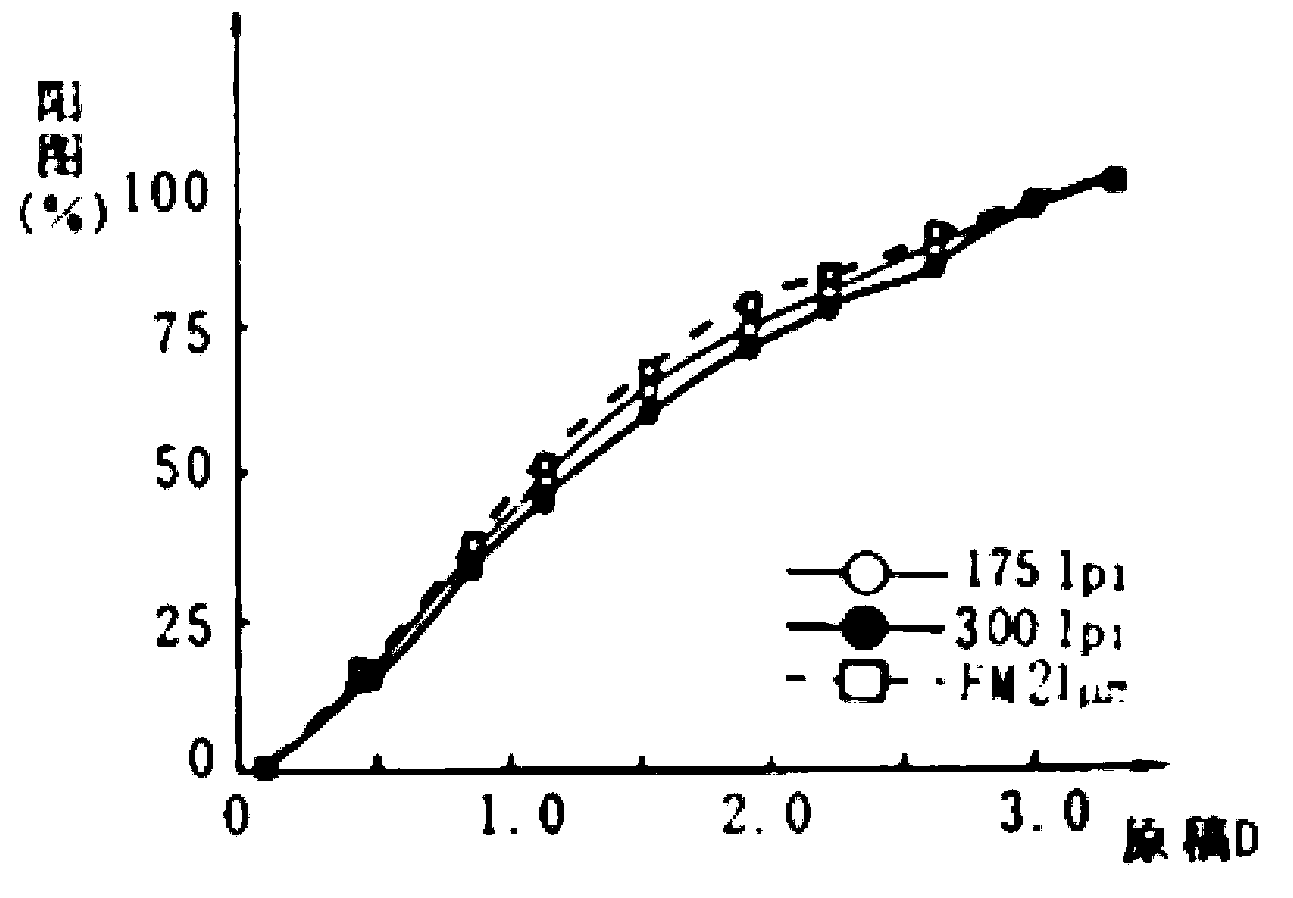

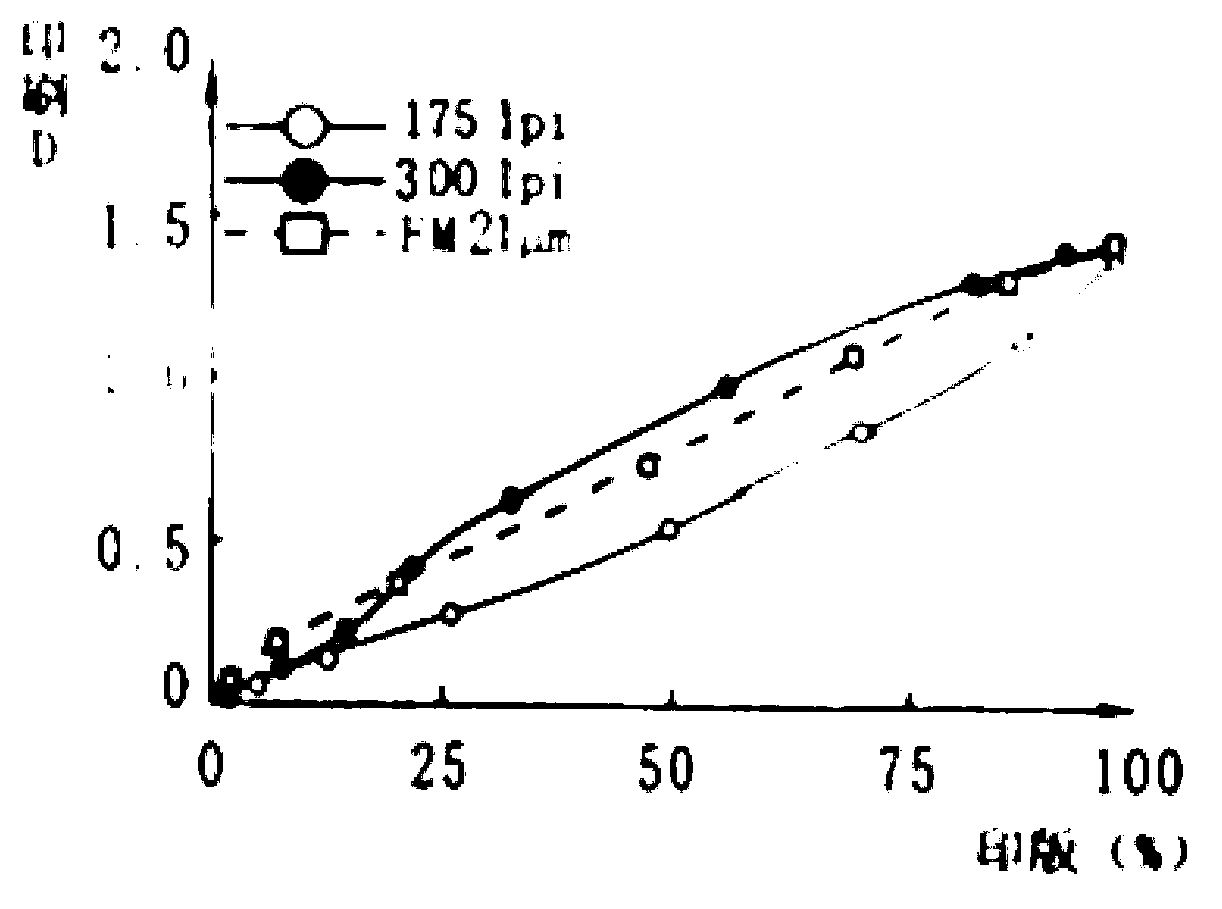

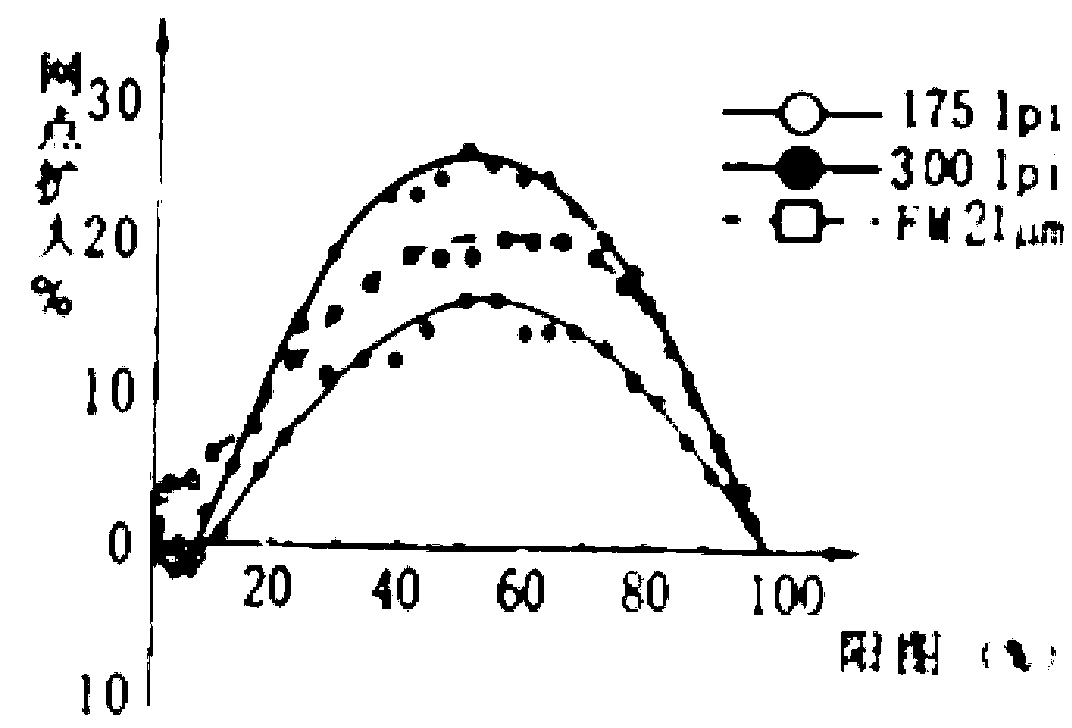

[0028] Data collection and analysis of the whole printing process

[0029] 1) Data collection of ink paper performance and suitability matching

[0030] ① Use X-RITE530 spectrodensitometer to test the color properties of various ink varieties, the selection of three primary color inks, and the test and deployment of operational suitability;

[0031] ②Determination of printability data of main paper varieties;

[0032] ③Printing operation suitability test and suitability processing, list records, for matching of different product objects.

[0033] 2) Adjustment of printing machine performance

[0034] ① Adjustment of the operating performance and embossing accuracy of the printing machine;

[0035] ②Fine test and adjustment of drum lining;

[0036] ③Test of printing pressure range and determination of ideal printing pressure.

[0037] 3) Testing and control of printing operation data

[0038] ① Under the conditions of specific printing equipment, ink, and paper, the deter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com