Flocculation treatment method for waste liquid of gravure wiping plate of centrifuge

A waste liquid treatment and waste liquid technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of complex synthesis process of cationic organic flocculants, insufficient active functional groups, small molecular weight of polycondensate, etc. Fast speed and the effect of reducing moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

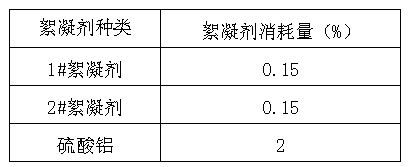

[0020] 1. Synthesis of cationic organic flocculants

[0021] 1) Synthesis of 1# flocculant—add 10 g of dicyandiamide, 5 g of aluminum chloride, 5 g of carbonamide, and ethylenediaminetetraacetic acid (EDTA) to 20 ml of formaldehyde solution with a mass fraction of 36%. ) 2g, stir evenly, then slowly add 20 ml of concentrated sulfuric acid while stirring, stir the reactant evenly and place it on an electromagnetic stirrer with heating function to heat to 60-70°C, stir at constant temperature for 2 hours, then cool to room temperature .

[0022] 2. Use of flocculant

[0023] 1) Pretreatment of plate wiping waste liquid

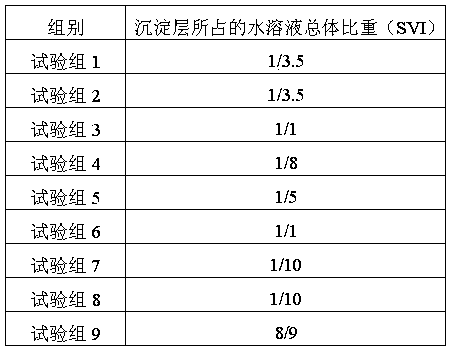

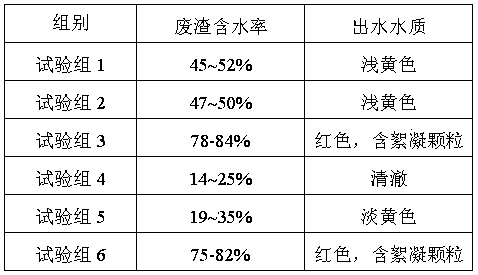

[0024] Heat the plate wiping waste liquid to 35-45°C, stir well, add sulfuric acid or other acids, adjust the pH of the plate wiping waste liquid to 7.5-9.5; add anhydrous calcium chloride after stirring evenly, the amount of anhydrous calcium chloride It is 0.1-0.5% (mass ratio) of the plate wiping waste liquid; the waste liquid is stirred at a constant spee...

Embodiment 2

[0028] 1. Synthesis of cationic organic flocculants

[0029] 1) Synthesis of 2# flocculant—add 10 g of dicyandiamide, 5 g of aluminum chloride, 5 g of carbonamide, and ethylenediaminetetraacetic acid (EDTA) to 55 ml of formaldehyde solution with a mass fraction of 36%. ) 2g, stir evenly, then slowly add 50 ml of hydrochloric acid with a mass fraction of 36% while stirring, stir the reactant evenly, heat to 60-70°C on an electromagnetic stirrer with heating function, and stir at constant temperature for 2 hours, Allow to cool to room temperature.

[0030] 2. Use of flocculant

[0031] The amount of 2# flocculant added is 0.15-0.5% (mass ratio) of the plate wiping waste liquid, which is diluted 10 times with tap water before use. When the flocculant is evenly added to the waste liquid, stirring should be continued, so that the flocculant can be mixed quickly and fully, and the flocculation reaction can be completed after stirring evenly.

[0032] The pretreatment of plate wip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com