Liquid compound reinforced type cement grinding aid and preparation method thereof

A technology of cement grinding aid and composite reinforcement, which is applied in the field of liquid composite reinforced cement grinding aid and its preparation, can solve the problems that cement enterprises cannot save costs, and the performance of grinding aid is single, so as to improve the physical and mechanical properties , Grinding aid enhances the effect, and the effect of good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

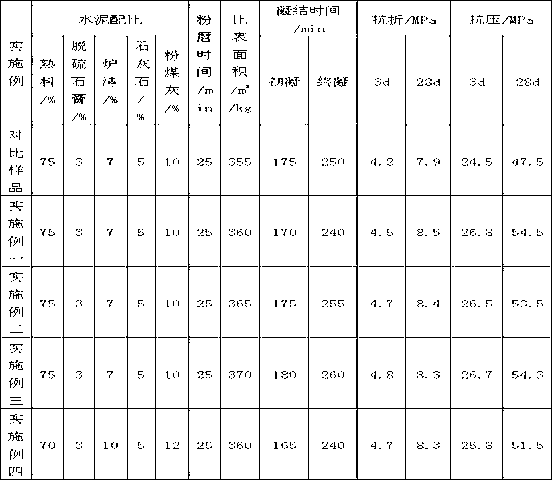

[0023] A liquid composite reinforced cement grinding aid, which is formulated by weight ratio from the following ingredients: 8 parts of sodium acetate, 15 parts of triethanolamine, 8 parts of ethylene glycol, 0.5 parts of block silicone oil, 30 parts of sulfamate, The rest is water. In the reaction kettle, the above-mentioned raw materials are mixed according to the weight ratio, and compounded according to the preparation process of the present invention to obtain the composite enhanced cement grinding aid. The dosage of the invention product in cement is 0.05% of the weight of cement (including mineral admixture). Weigh 5 kg of cement raw material and 2.5 g of grinding aid, and compare and analyze the physical and mechanical properties of the cement before and after the use of the grinding aid. After grinding in a ball mill for 25 minutes, the cement test results are shown in Table 1.

Embodiment 2

[0025] A liquid composite enhanced cement grinding aid, which is prepared by weight ratio from the following ingredients: 8 parts of sodium acetate, 5 parts of sodium thiosulfate, 10 parts of triethanolamine, 18 parts of diethanol isopropanolamine, block silicone oil 0.3 parts, 35 parts of sulfamate, and the rest is water. In the reaction kettle, the above-mentioned raw materials are mixed according to the weight ratio, and compounded according to the preparation process of the present invention to obtain the composite enhanced cement grinding aid. The dosage of the invention product in cement is 0.03% of the weight of cement (including mineral admixture). Weigh 5 kg of cement raw material and 1.5 g of grinding aid, and compare and analyze the physical and mechanical properties of the cement before and after the use of the grinding aid. After grinding in a ball mill for 25 minutes, the cement test results are shown in Table 1.

Embodiment 3

[0027] A liquid composite reinforced cement grinding aid, which is prepared by weight ratio from the following ingredients: 3 parts of sodium tripolyphosphate, 10 parts of sodium acetate, 15 parts of diethanolamine, 6 parts of tetrahydroxyethylhexamethylenediamine, block 0.2 parts of silicone oil, 10 parts of lignin iodate, 20 parts of sulfamate, and the rest is water. In the reaction kettle, the above-mentioned raw materials are mixed according to the weight ratio, and compounded according to the preparation process of the present invention to obtain the composite enhanced cement grinding aid. The dosage of the invention product in cement is 0.03% of the weight of cement (including mineral admixture). Weigh 5 kg of cement raw material and 2.5 g of grinding aid, and compare and analyze the physical and mechanical properties of the cement before and after the use of the grinding aid. After grinding in a ball mill for 25 minutes, the cement test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com