High-performance composite material heat-insulting board and preparation method thereof

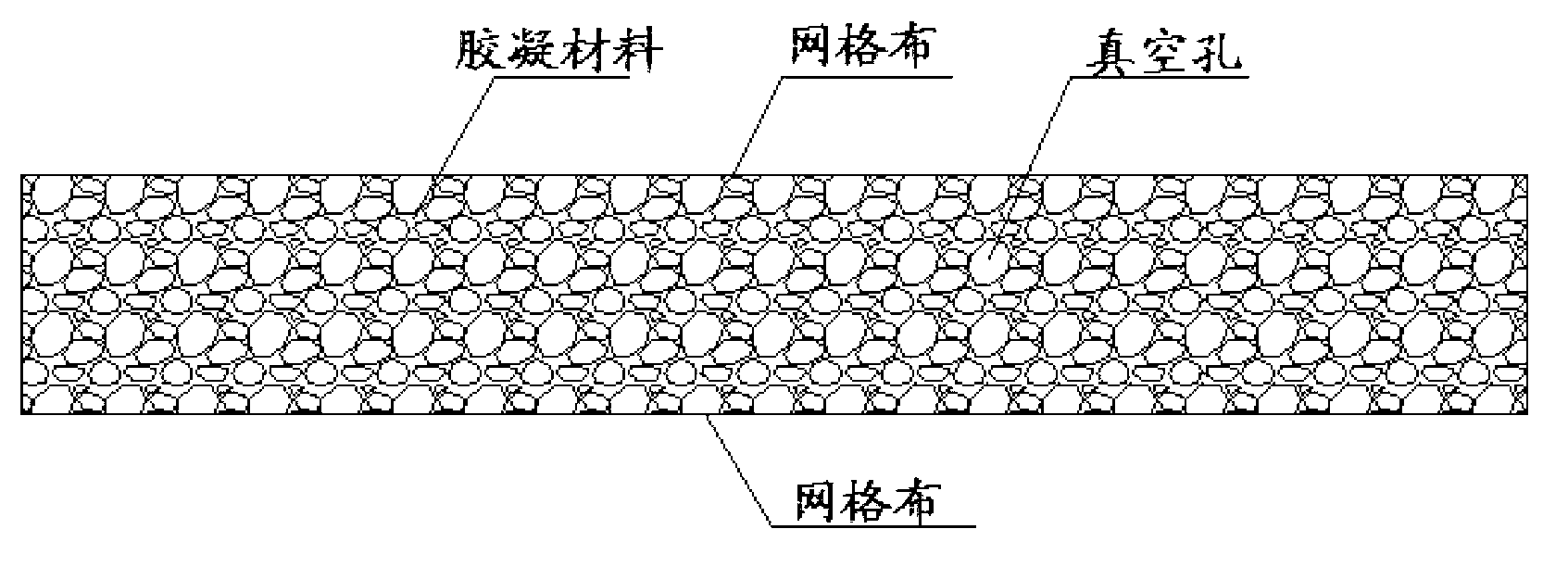

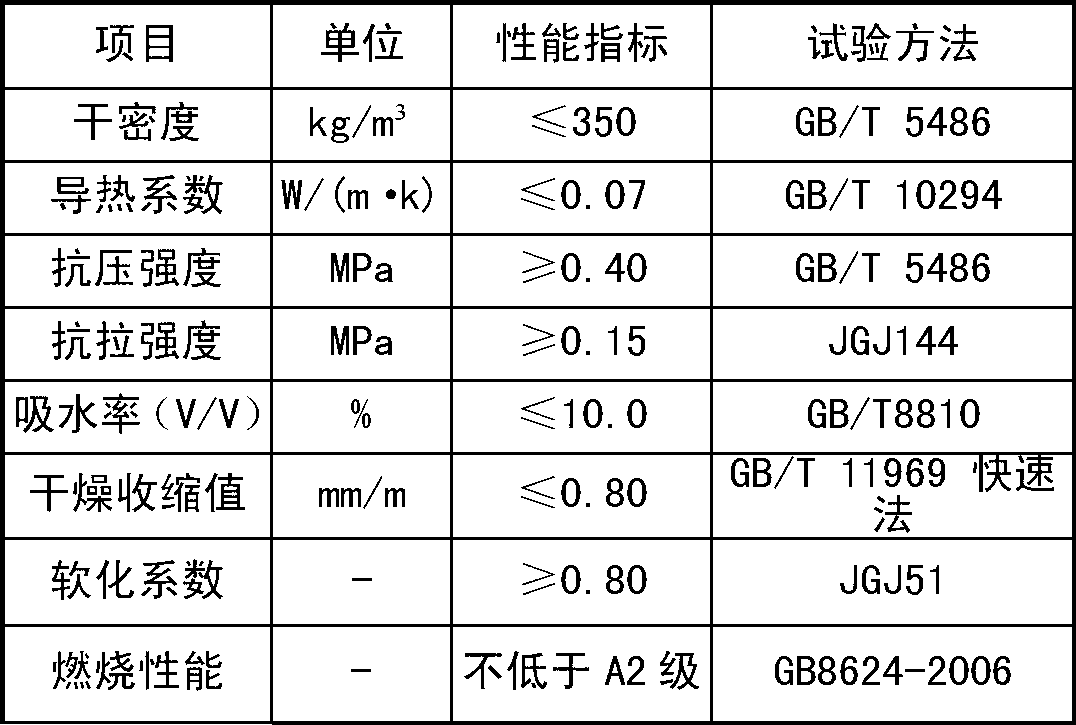

A technology of composite materials and thermal insulation boards, which is applied in the field of thermal insulation materials to achieve the effects of low dry density and excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

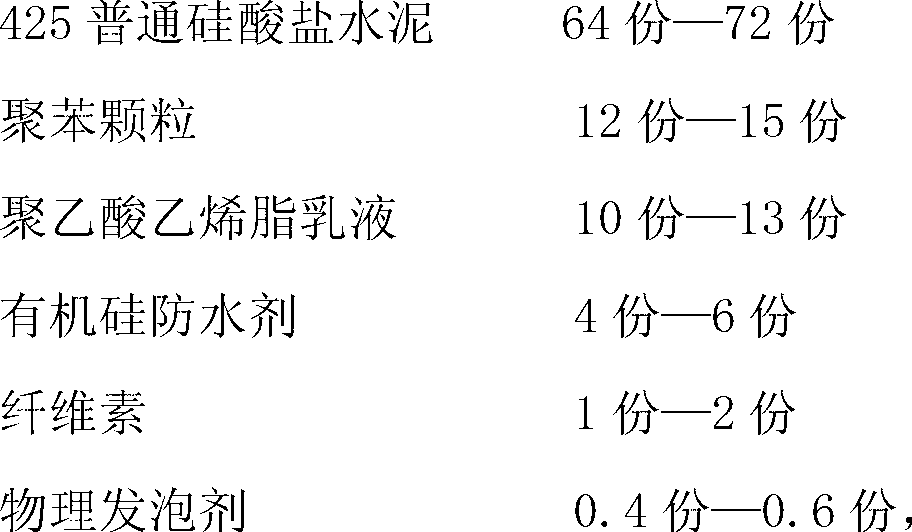

[0029] Parts by weight of component raw materials:

[0030] 67.6 parts of 425 ordinary Portland cement

[0031] The particle size is 3-5mm, and the bulk density is 19-25Kg / m 3 15 parts of polystyrene particles

[0032] 10 parts of polyvinyl acetate emulsion with a solid content of 55%

[0033] 6 parts of organosilicon water repellent of model BD-s111 produced by Hangzhou Baoerde Silicone Co., Ltd.

[0034] 1 part of 100,000-grade hydroxypropyl methylcellulose HPMC

[0035] 0.4 parts of animal foaming agent produced by Yantai Chilong Building Energy Saving Technology Co., Ltd.

[0036] Step (1) First, take 0.4 parts of physical foaming agent, use the FP-18B cement foaming machine of Yantai Chilong Energy Saving Technology Co., Ltd., and use the physical foaming method to make foam according to its operating requirements;

[0037] Step (2) Mix 425 ordinary Portland cement, polystyrene particles, polyvinyl acetate emulsion, silicone waterproofing agent and cellulose accordin...

Embodiment 2

[0044] Parts by weight of component raw materials:

[0045] 425 Ordinary Portland Cement 68.5 parts

[0046] The particle size is 3-5mm, and the bulk density is 19-25Kg / m 3 13 parts of polystyrene particles

[0047] 11 parts of polyvinyl acetate emulsion with a solid content of 58%

[0048] 5 parts of organic silicon waterproofing agent of model BD-s111 produced by Hangzhou Baoerde Silicone Co., Ltd.

[0049] 2 parts of 100,000-grade hydroxypropyl methylcellulose HPMC

[0050] 0.5 parts of animal-type foaming agent produced by Yantai Chilong Building Energy Saving Technology Co., Ltd.

[0051] Step (1) First take 0.5 parts of physical foaming agent, use the FP-18B cement foaming machine of Yantai Chilong Energy Saving Technology Co., Ltd., and use the physical foaming method to make foam according to its operating requirements;

[0052] Step (2) Mix 425 ordinary Portland cement, polystyrene particles, polyvinyl acetate emulsion, silicone waterproofing agent and cellulose ...

Embodiment 3

[0059] Parts by weight of component raw materials:

[0060] 425 Ordinary Portland Cement 69.4 parts

[0061] The particle size is 3-5mm, and the bulk density is 19-25Kg / m 3 12 parts of polystyrene particles

[0062] 13 parts of polyvinyl acetate emulsion with a solid content of 60%

[0063] 4 parts of organosilicon water repellent of model BD-s111 produced by Hangzhou Baoerde Silicone Co., Ltd.

[0064] 1 part of 100,000-grade hydroxypropyl methylcellulose HPMC

[0065] 0.6 parts of animal foaming agent produced by Yantai Chilong Building Energy Saving Technology Co., Ltd.

[0066] Step (1) First, take 0.6 parts of physical foaming agent, use the FP-18B cement foaming machine of Yantai Chilong Energy Saving Technology Co., Ltd., and use the physical foaming method to make foam according to its operating requirements;

[0067]Step (2) Mix 425 ordinary Portland cement, polystyrene particles, polyvinyl acetate emulsion, silicone waterproofing agent and cellulose according to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water absorption | aaaaa | aaaaa |

| Water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com