SBS modified asphalt with affinity group and preparation method thereof

A technology of modified asphalt and matrix asphalt, which is applied to building components, building insulation materials, buildings, etc., and can solve problems such as high difficulty and waste products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] The preparation method of the SBS modified asphalt with affinity group comprises the steps:

[0030] A. 75-95% by weight of base asphalt is injected into a weighing container equipped with a stirrer from a heat exchange system with a low-temperature heat exchanger via an asphalt pump, and 75-95% by weight of base asphalt is heated to 170 ℃~180℃;

[0031] B. Add 3-10% by weight of SBS and 0.5-6% by weight of co-solvent into the base asphalt, stir for 25-30 minutes, and send it into the swelling container through a high-power asphalt pump;

[0032] C. Add 0.5-5% by weight stabilizer and 2-10% by weight affinity group additive in sequence, keep the temperature in the range of 170-180°C, and stir for 35-45 min;

[0033] D. The mixture obtained in step C is sheared and dispersed with a pipeline shearer, sent into a storage tank with a pipeline pump, and then developed again for 1h to 3h to obtain the SBS with the affinity group modified asphalt.

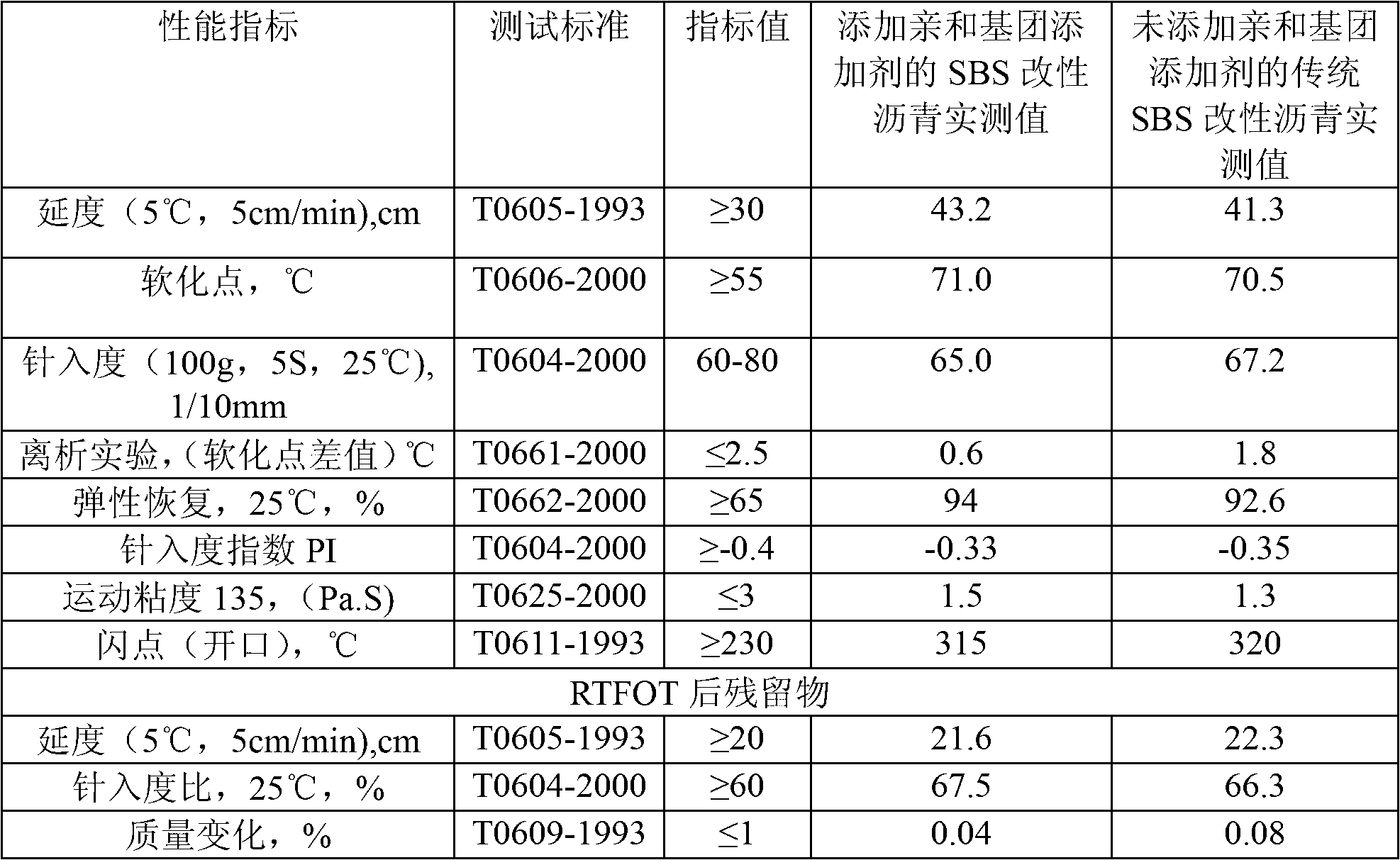

[0034] Table 1 shows the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com