Setting method in sections of high alloy steel vacuum heat treatment high-temperature region parameters

A vacuum heat treatment and high-alloy steel technology, applied in heat treatment equipment, heat treatment process control, manufacturing tools, etc., can solve the problems of prolonged holding time, difficult heat treatment process parameters, slow heating speed, etc., to achieve small quenching stress and reduce heat treatment The effect of distortion and high red hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

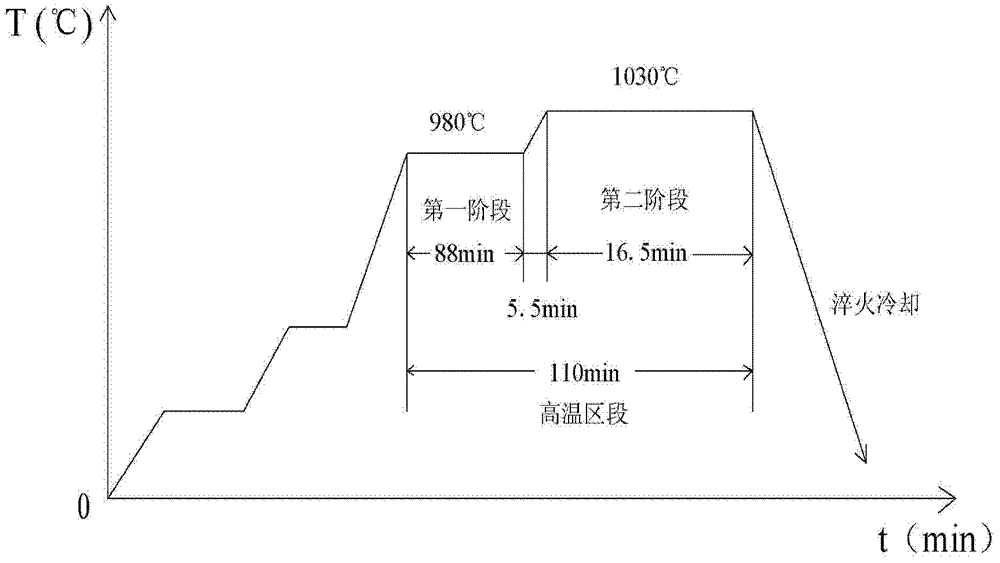

[0016] Set the final heating temperature of SKD61 to 1030°C, and the total holding time in the high temperature zone is 110min, then:

[0017] (1) The first-stage heating temperature and first-stage holding time parameters in the high-temperature zone are set as follows:

[0018] Heating temperature: 980°C

[0019] Holding time: total holding time in high temperature zone × 80%, that is, 110min × 80% = 88min.

[0020] (2) The parameters of the second stage heating temperature and the second stage holding time in the high temperature zone are set as follows:

[0021] Heating temperature: 1030°C

[0022] Holding time: total holding time in high temperature zone × 15%, that is, 110min × 15% = 16.5min.

[0023] (3) Setting of heating time parameters between the first stage in the high temperature zone and the second stage in the high temperature zone:

[0024] The time required to raise the temperature from 980°C to 1030°C: the total holding time in the high temperature zone ×...

Embodiment 2

[0028] Set the final heating temperature of SKD61 to 1300°C, and the total holding time in the high temperature zone is 100min, then:

[0029] (1) The first-stage heating temperature and first-stage holding time parameters in the high-temperature zone are set as follows:

[0030] Heating temperature: 1000°C

[0031] Holding time: total holding time in high temperature zone × 80%, that is, 100min × 80% = 80min.

[0032] (2) The parameters of the second stage heating temperature and the second stage holding time in the high temperature zone are set as follows:

[0033] Heating temperature: 1300°C

[0034] Holding time: total holding time in high temperature zone × 15%, that is, 100min × 15% = 15min.

[0035] (3) Setting of heating time parameters between the first stage in the high temperature zone and the second stage in the high temperature zone:

[0036] The time required to raise the temperature from 1000°C to 1300°C: the total holding time in the high temperature zone ×...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com