Preparation method for complex-shape niobium-based ODS (oxide dispersion strengthening) alloy

A complex shape, niobium-based technology, applied in the field of refractory metal preparation, to achieve the effect of short manufacturing cycle, high material utilization rate and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

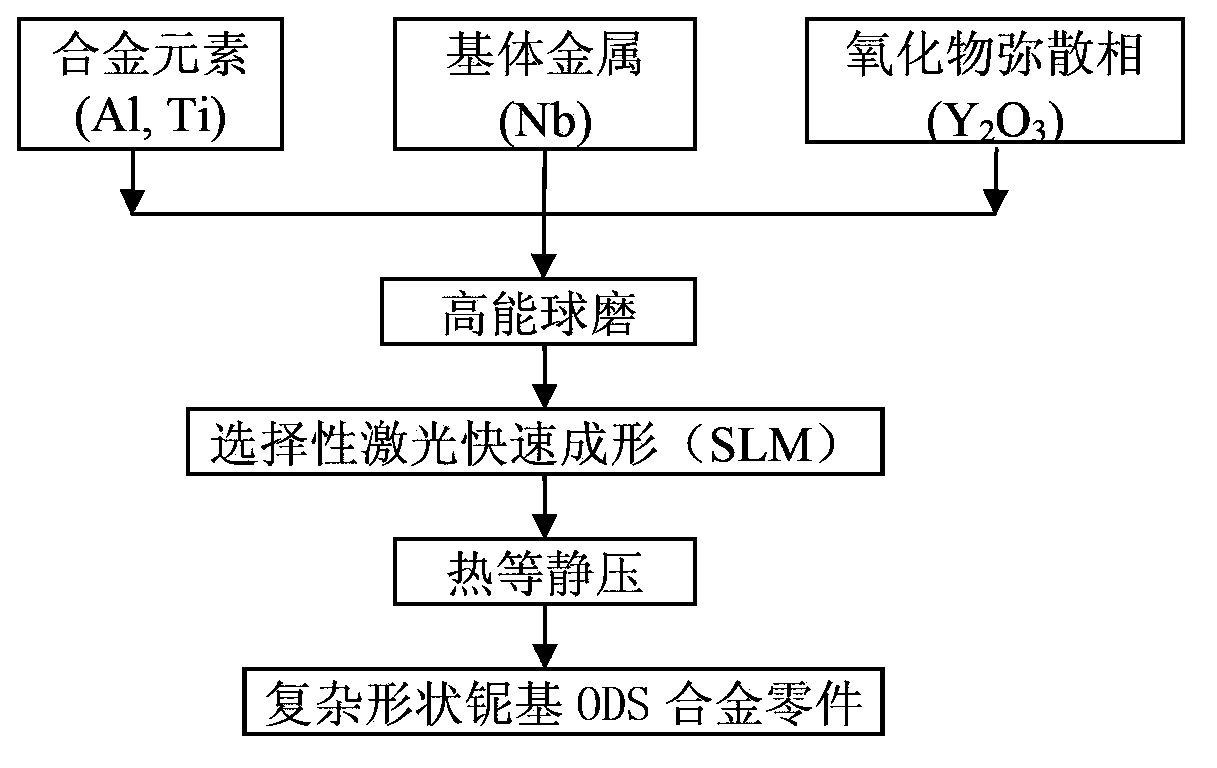

Method used

Image

Examples

Embodiment 1

[0013] Example 1: Preparation of Nb-Al-based ODS alloy with complex shape

[0014] Use high-purity niobium powder, aluminum powder and Y with particle size of 20~30nm 2 o 3 Powder is used as the raw material, and the ratio is as follows: 15wt.%Al-0.3wt.%Y 2 o 3 - margin Nb. Add 0.5wt.% stearic acid to the raw material powder and pre-mix evenly, and then carry out high-energy ball milling of the mixed powder in a high-purity Ar atmosphere to make Y 2 o 3 The particles are uniformly dispersed in the niobium matrix, the ball / material ratio is 15 / 1, the rotational speed of the ball mill is 380 rpm, and the ball milling time is 40 hours to obtain niobium-based ODS alloy powder. Secondly, CAD software is used to design the 3D solid model of the part, and then the 3D model is sliced into layers to discretize it into a series of 2D layers. At the same time, the powder spreading system of the SLM forming machine spreads a layer of niobium-based ODS alloy powder on the working...

Embodiment 2

[0015] Example 2: Preparation of Nb-Al-based ODS alloy with complex shape

[0016] Use high-purity niobium powder, aluminum powder and Y with particle size of 20~30nm 2 o 3 Powder is used as raw material, and the ratio is as follows: 20wt.%Al-1.0wt.%Y 2 o 3 - margin Nb. Add 1wt.% stearic acid to the raw material powder and pre-mix evenly, and then carry out high-energy ball milling of the mixed powder in a high-purity Ar atmosphere to make Y 2 o 3 The particles are uniformly dispersed in the niobium matrix, the ball / material ratio is 15 / 1, the rotational speed of the ball mill is 380 rpm, and the ball milling time is 40 hours to obtain niobium-based ODS alloy powder. Secondly, CAD software is used to design the 3D solid model of the part, and then the 3D model is sliced into layers to discretize it into a series of 2D layers. At the same time, the powder spreading system of the SLM forming machine spreads a layer of niobium-based ODS alloy powder on the working platf...

Embodiment 3

[0017] Example 3: Preparation of complex shape Nb-Al-Ti based ODS alloy

[0018] High-purity niobium powder, aluminum powder, titanium powder and Y powder with particle size of 20~30nm 2 o 3 Powder is the raw material, and the proportion is as follows: 15wt.%Al-25wt.%Ti-1.5wt.%Y 2 o 3 - margin Nb. Add 1.5wt.% stearic acid to the raw material powder and pre-mix evenly, and then carry out high-energy ball milling of the mixed powder in a high-purity Ar atmosphere to make Y 2 o 3 The particles are uniformly dispersed in the niobium matrix, the ball / material ratio is 15 / 1, the rotational speed of the ball mill is 380 rpm, and the ball milling time is 40 hours to obtain niobium-based ODS alloy powder. Secondly, CAD software is used to design the 3D solid model of the part, and then the 3D model is sliced into layers to discretize it into a series of 2D layers. At the same time, the powder spreading system of the SLM forming machine spreads a layer of niobium-based ODS all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| service temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com