Sea grass fiber mattress and preparation method thereof

A fiber mat and seaweed technology, applied in the field of seagrass fiber mat and its preparation, can solve the problems of general antibacterial effect of mattresses and achieve good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

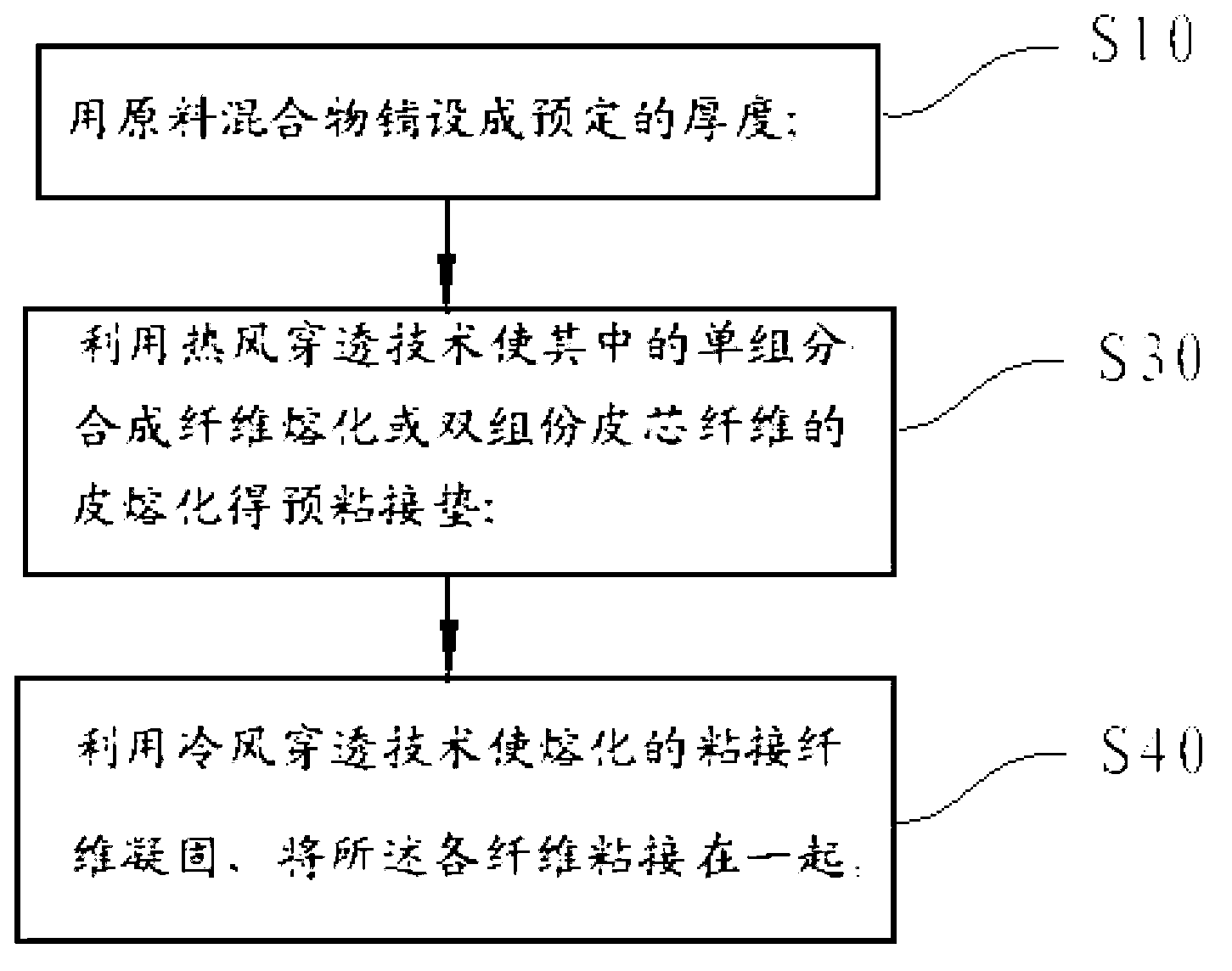

[0028] see figure 1 , the preparation method of seagrass fiber mat of the present invention, comprises the following steps:

[0029] S10, laying the raw material mixture to a predetermined thickness;

[0030] S30, using hot air penetration technology to melt the single-component synthetic fiber or the sheath of the two-component sheath-core fiber to obtain a pre-bonded mat;

[0031] S40. Using the cold air penetration technique to solidify the melted bonding fibers, and bonding the fibers together.

[0032] The seagrass fiber mat prepared by the preparation method of the present invention has no formaldehyde release, no glue smell, is not easy to be damp and mildewed, has a smooth surface, uniform thickness, good hygroscopicity, is not easy to grow insects, is antibacterial, fastens the fibers, and has high tensile strength.

[0033] Preferably, in order to obtain a seagrass fiber mat with better mechanical properties, a step S20 is further included between step S10 and step...

Embodiment 1

[0040] A seagrass fiber mat, the raw material mixture used in the preparation includes the following components in weight percentage: 30% of the first plant fiber, 40% of the second plant fiber, 30% of the bonding fiber;

[0041] The first plant fiber is seagrass fiber, the second plant fiber is jute fiber; the bonding fiber is a two-component sheath-core fiber, the skin of the two-component sheath-core fiber is PET with a melting point of 110°C, and the core is PET with a melting point of 265°C.

[0042] The specific preparation method of the seagrass fiber mat of the present embodiment is carried out as follows:

[0043] (S110) laying the raw material mixture with a thickness of 5 cm;

[0044] (S130) using hot air penetration technology to penetrate with 180°C hot air to melt the sheath of the two-component sheath-core fiber;

[0045] (S140) Using the cold air penetration technique to solidify the melted bonding fibers with cold air at 5°C, and bonding the fibers together ...

Embodiment 2

[0047] A seagrass fiber mat, the raw material mixture used in the preparation includes the following components in weight percentage: 60% of the first plant fiber, 20% of the second plant fiber, 20% of the bonding fiber;

[0048] The first plant fiber is seagrass fiber, the second plant fiber is soybean fiber; the bonding fiber is polypropylene fiber filament with a melting point lower than that of seaweed fiber and soybean fiber.

[0049] The specific preparation method of the seagrass fiber mat of the present embodiment is carried out as follows:

[0050] (S210), laying the raw material mixture with a thickness of 10cm;

[0051] (S220), the laid raw material mixture is pre-shaped by needle punching to form a pre-shaped mat, and the needle density is 2500 needles / m 2 , the diameter of the needle is 3.5 mm, and the pre-shaped acupuncture is first pierced once from the bottom to the bottom, and then pierced from the top to the bottom.

[0052] (S230), using hot air penetratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com