Water hammer type well drill

A drilling machine and water hammer technology, applied in the field of piling and well drilling, can solve the problems of high production cost, high construction cost, waste of energy, and great influence on surrounding residents, and achieve low manufacturing cost, reduced construction cost, and high energy utilization rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

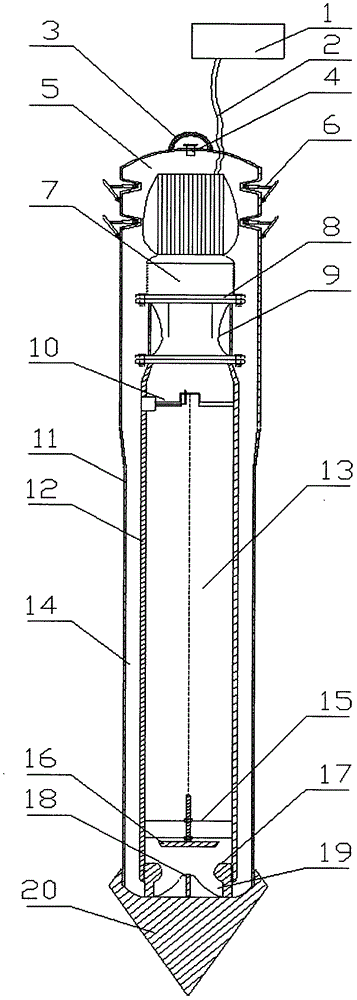

[0030] Such as figure 1 As shown, 1 numerical control box is on the ground, connect the drilling machine with 2 cables, increase the power supply to the drilling machine, and manually control the movement of the 6-direction controller, control the operation and speed of the 7-water pump, and control the start-up of the 10-valve board speed of the machine.

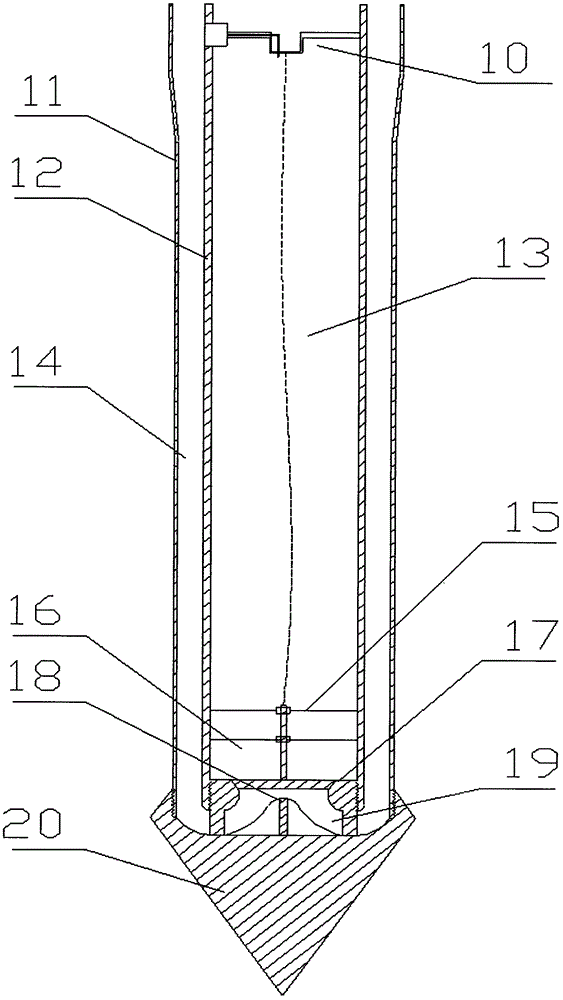

[0031] Such as figure 2 As shown, the valve plate 16 is on the base of the valve 17, and the water flow channel in the water hammer pipeline of the 13 can be closed or opened by moving the valve plate 16 up and down. The 16 valve plate is a disk, and its surface is a convex cone; the 17 valve base is a ring, and its surface is a concave cone, when the 16 valve plate and the 17 valve base are closed, there is no gap between the two, and the 17 valve base has Eight legs, distributed in a regular octagon, are welded on concentric circles of 20 drill bits.

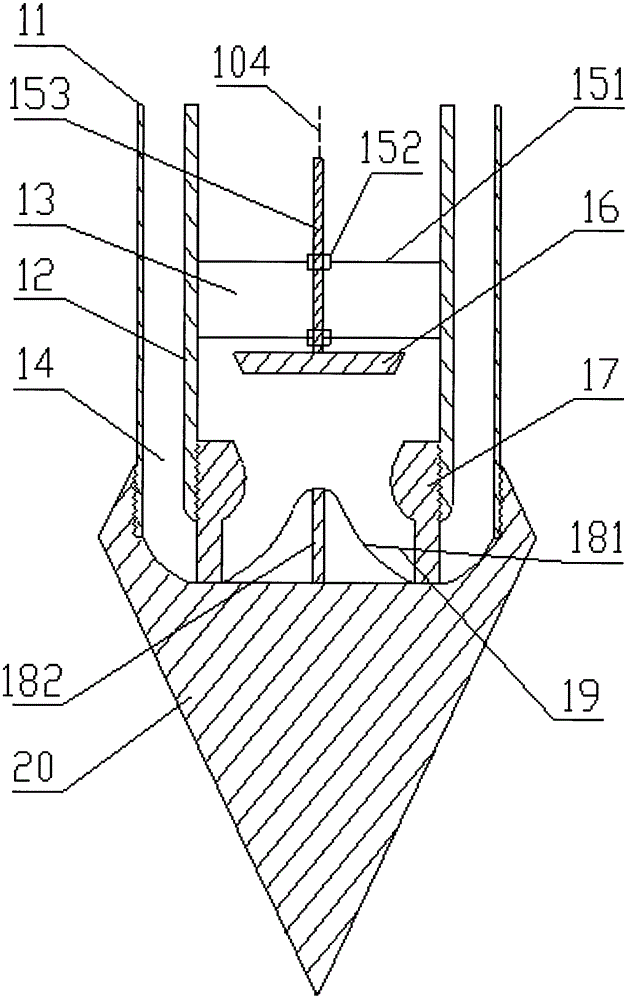

[0032] Such as image 3 As shown, the shell of 11 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com