Cleaning and anti-scaling process without shut-down of gas-gas heater (GGH) and device thereof

A cleaning device and process technology, which is applied in the field of cleaning and scale inhibition, can solve the problems of increasing the unplanned shutdown assessment pressure of power plants and reducing the power generation revenue of power plants, so as to achieve the effects of safe and stable operation of production equipment, avoiding economic penalties, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

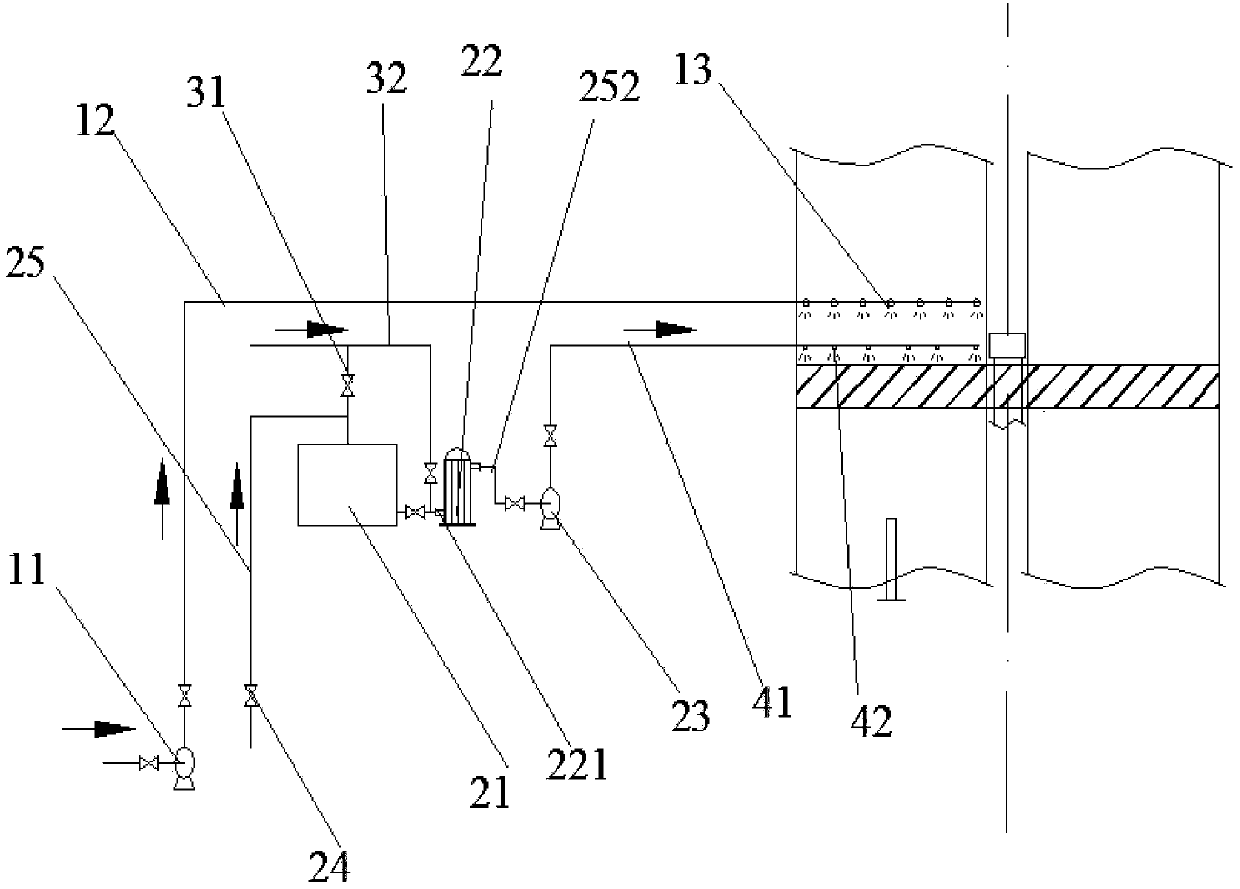

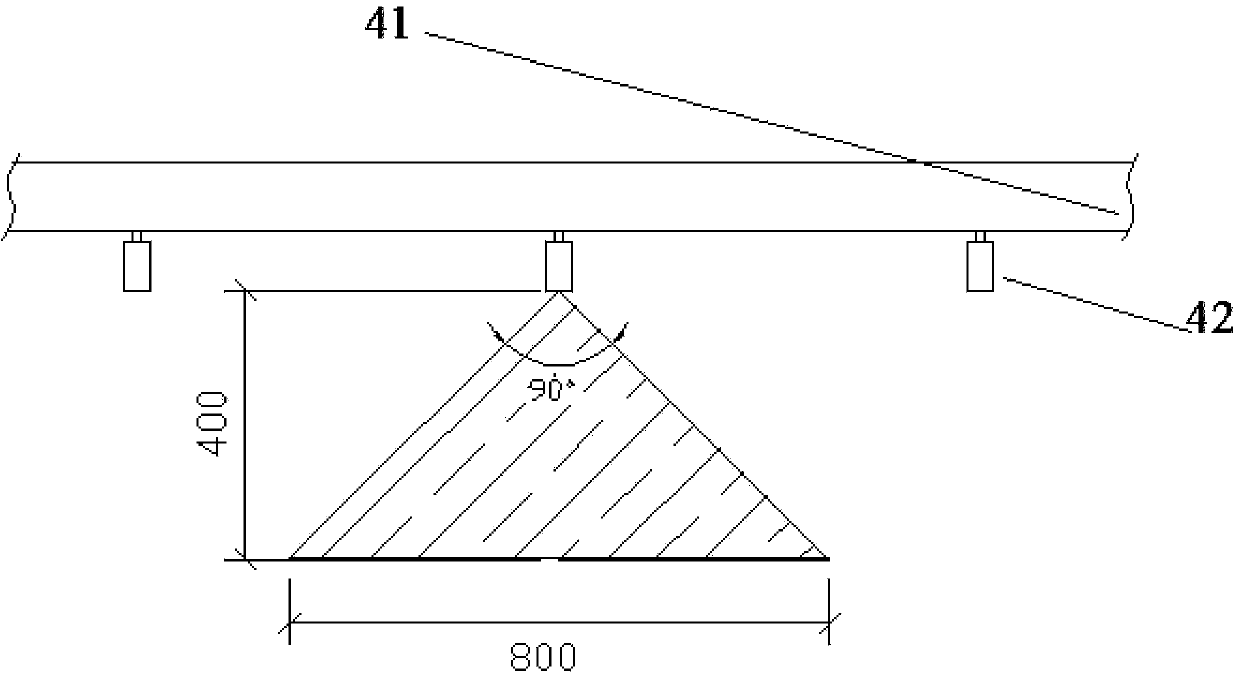

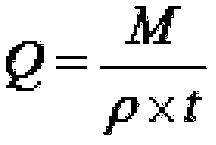

[0037] A 1000MW unit is equipped with an online cleaning device and a high-pressure flushing device on the GGH system. The online cleaning device includes: a dosing device and a chemical spraying device. The output of the dosing device is connected to the The medicine spraying device is connected; the high-pressure flushing device includes a high-pressure water outlet 11 and a high-pressure water spraying device 13 connected through a high-pressure water pipeline 12;

[0038] The process described is: under the condition that the surface of the heat exchange element is kept moist, control the frequency of medication, calculate the pre-coating amount of the agent and the spraying amount of the agent, spray the agent for 15 minutes according to the calculated amount, and after the interval of 15 minutes after the spraying of the agent, Use the medicament spray device to replenish water. After 5 consecutive replenishments, start the high-pressure flushing device and rinse for 60 m...

Embodiment 2

[0052] A 300MW unit is equipped with an online cleaning device and a high-pressure flushing device on the GGH system. The online cleaning device includes: a dosing device and a chemical spraying device. The output of the dosing device is connected to the The medicine spraying device is connected; the high-pressure flushing device includes a high-pressure water outlet 11 and a high-pressure water spraying device 13 connected through a high-pressure water pipeline 12;

[0053] The process described is: under the condition that the surface of the heat exchange element is kept moist, control the frequency of medication, calculate the pre-coating amount of the agent and the spraying amount of the agent, spray the agent for 15 minutes according to the calculated amount, and after the interval of 15 minutes after the spraying of the agent, Use the medicament spray device to replenish water. After 5 consecutive replenishments, start the high-pressure flushing device and rinse for 60 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com