Layered soil moisture lysimeter sensor and installation method thereof

A soil moisture, layered technology, applied in the field of sensors, can solve the problems such as the inability to instantly and continuously collect data of soil moisture exchange information, the inconvenience of soil moisture transport information collection and simulation research, and the large interference of human factors. Simple, low cost, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

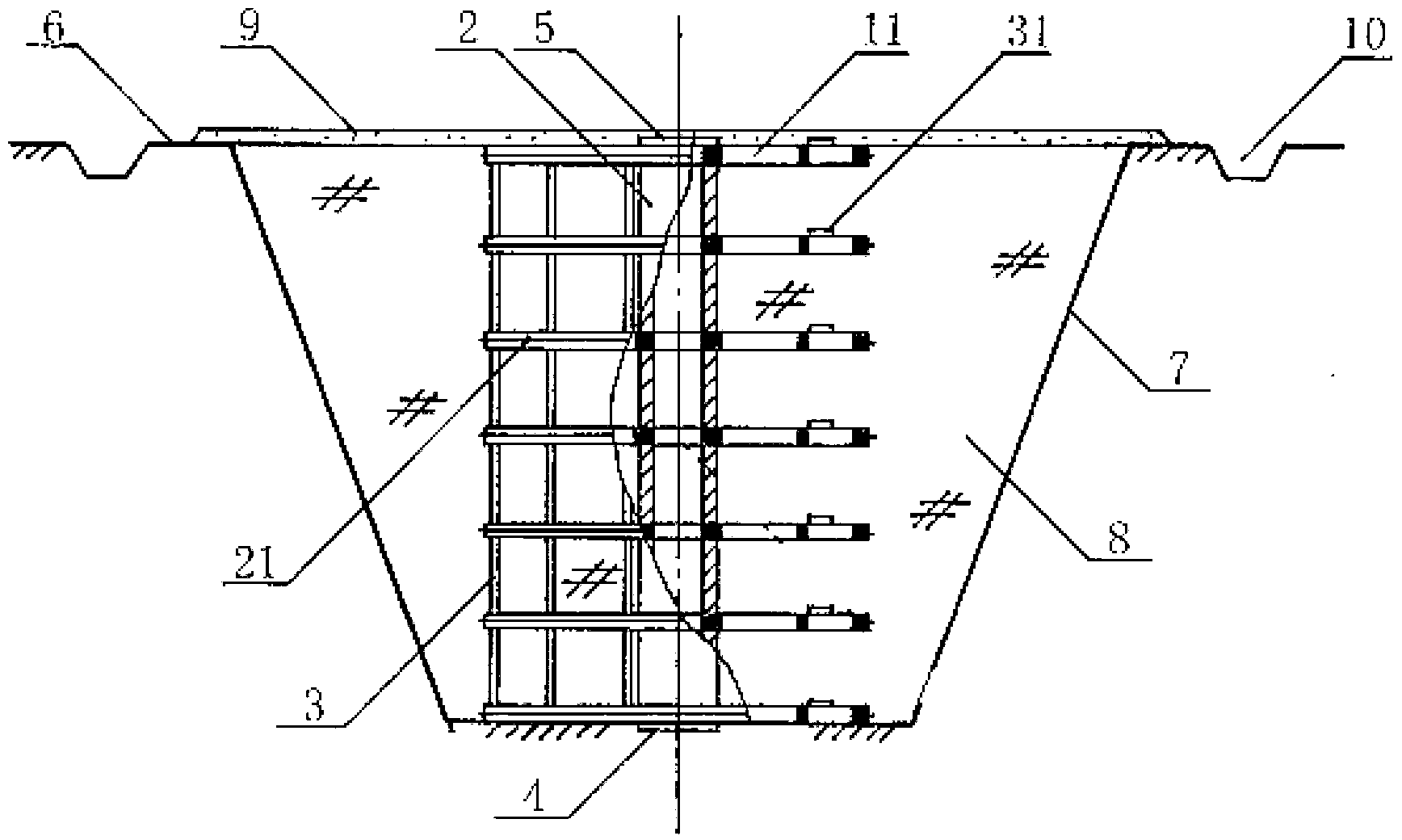

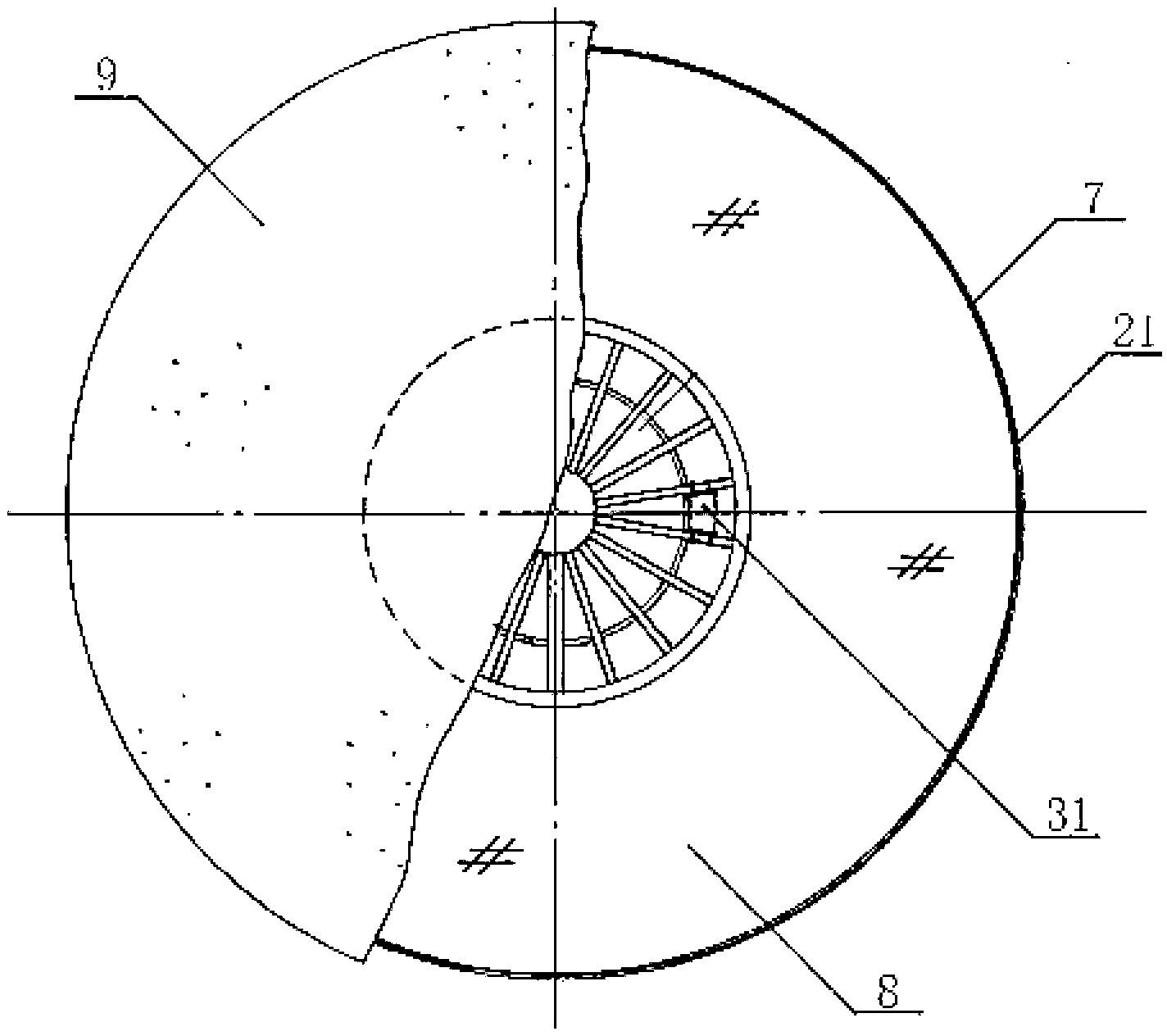

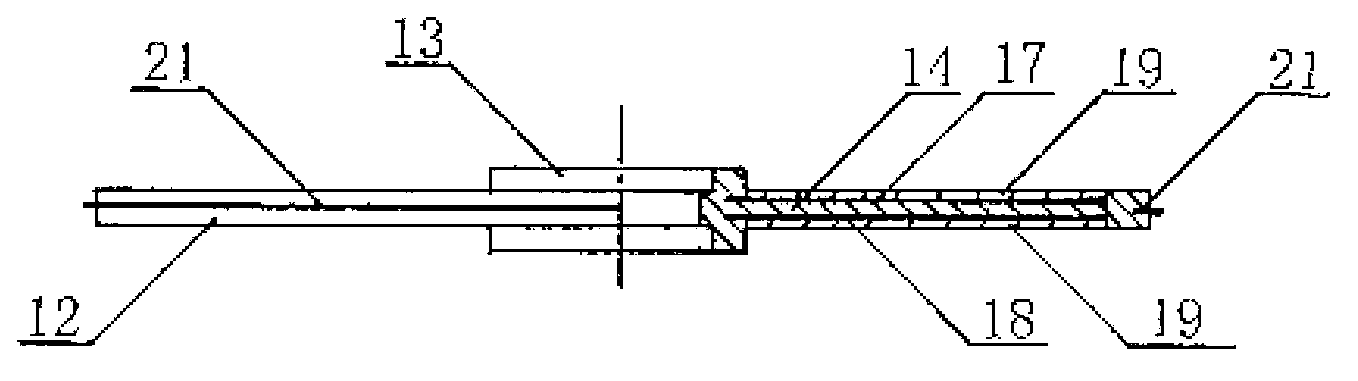

[0028] Such as figure 1 , 2 As shown, a layered soil moisture lysimeter sensor includes several layers of horizontally arranged lysimeter sheets 11, and a fixed seat 13 is arranged in the middle of the lysimeter sheets 11, and each layer of lysimeter sheets The fixing seats 13 of the sheets 11 are all fixed by the vertical cylinder joints 2, and several positioning rods 3 are equidistantly arranged between the lysimeter sheets 11 of each layer to support the positioning, and the lysimeter sheets 11 of each layer are installed There are conductivity electrode rings 21 and heat-sensitive devices 31, and the original test soil 8 is filled between each layer of lysimeter moisture-sensitive sheets 11 to form soil moisture lysimeter sensors connected in series at equal intervals, and the lysimeter of the top layer The humidity sensing sheet 11 is flush with the ground 6, the top layer lysimeter sensing sheet 11 has a cover plate 5 on the top surface of the fixing seat 13, the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com