12 core melting and assembling integrated tray

A kind of pallet and fusion technology, applied in the direction of fiber mechanical structure, etc., can solve problems such as insufficient power, and achieve the effect of reducing types, optimizing structure, and improving engineering construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

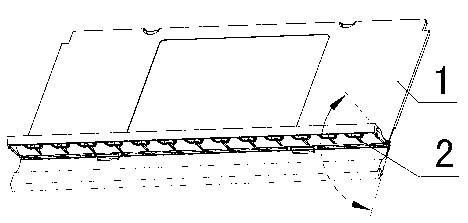

[0014] Control attached figure 1 , the structure of the cover plate and the movable flap includes a cover plate 1 and a movable flap 2, wherein the movable flap 2 is connected to the cover plate 1 through a hinged joint, and then the whole is covered on the welding tray and the terminal tray. When the adapter needs to be replaced on site , only need to open the movable flap 2, the movable flap 2 can be turned over 90 degrees from the horizontal position to the vertical position, and the adapter can be easily replaced without opening the entire cover 1.

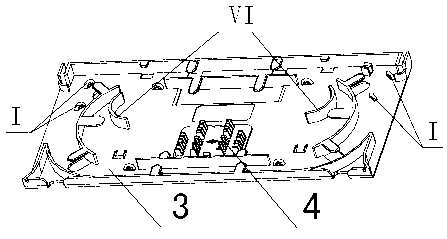

[0015] Control attached figure 2 , the structure of the welding tray and the movable welding chip includes the welding tray 3 and the movable welding chip 4; the I on the welding tray 3 is the outer cable introduction area, which can meet the introduction and fixing of the leather cable through the design update. According to the rules of the fiber tray in the tray, the outer optical cables on both sides of the hot-melt poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com