Hundred-megawatt level heavy type flywheel energy storage system based on gas magnetic fluid float cylinder suspension

A flywheel energy storage, megawatt-level technology, applied in the field of energy storage systems, can solve the problems of large magnetic suspension current of heavy shafts, difficult suspension of shafts, and unfavorable popularization. infinite effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

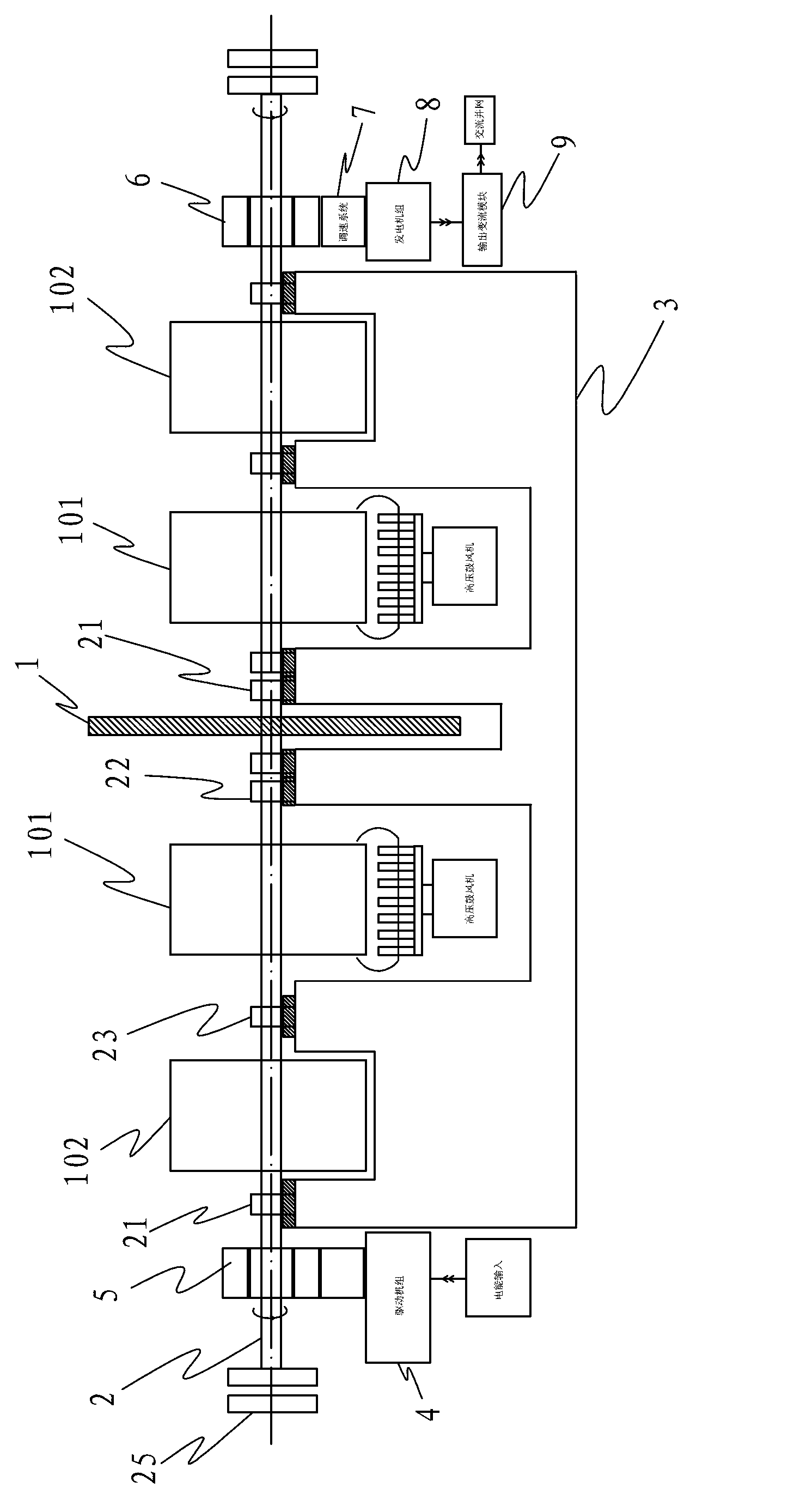

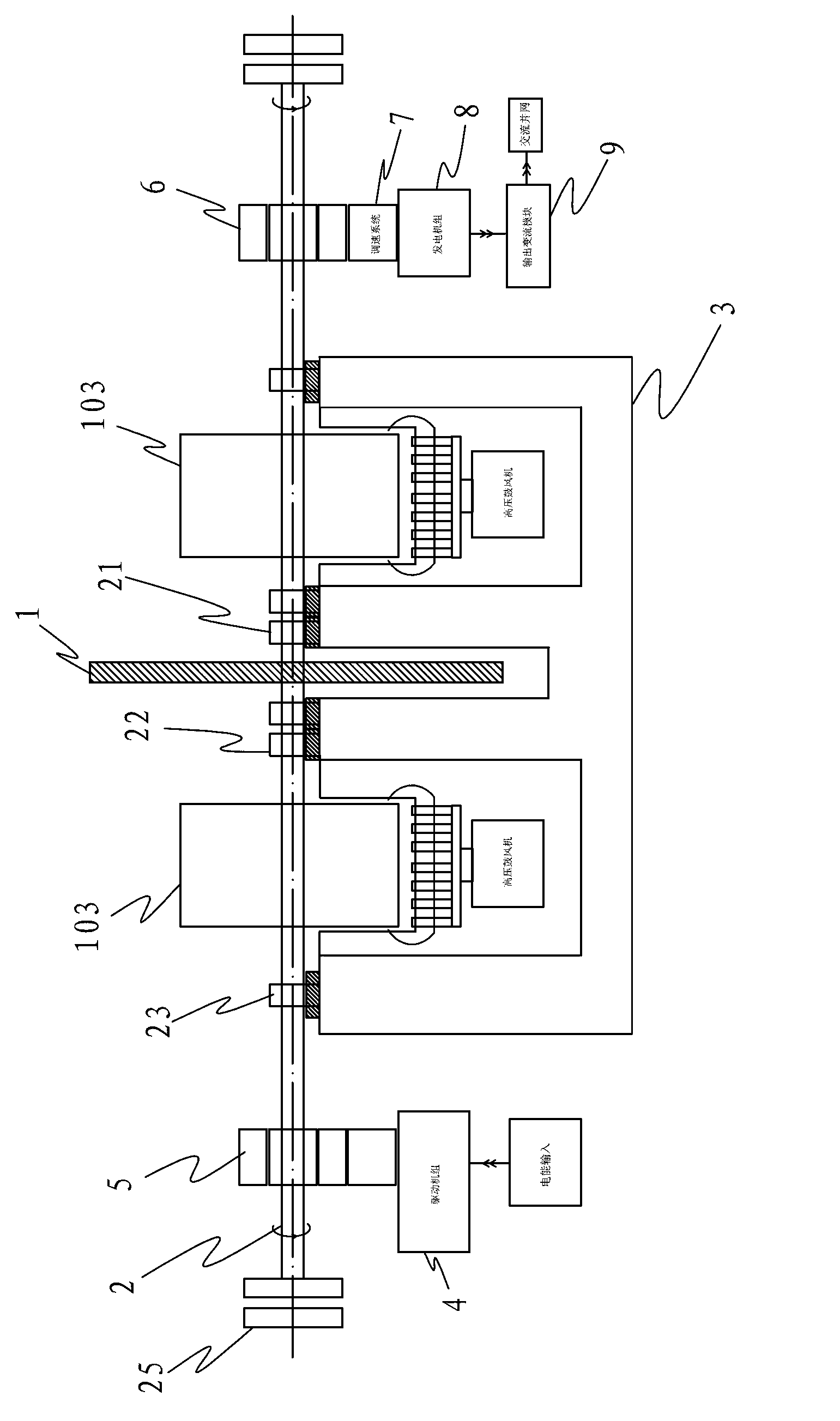

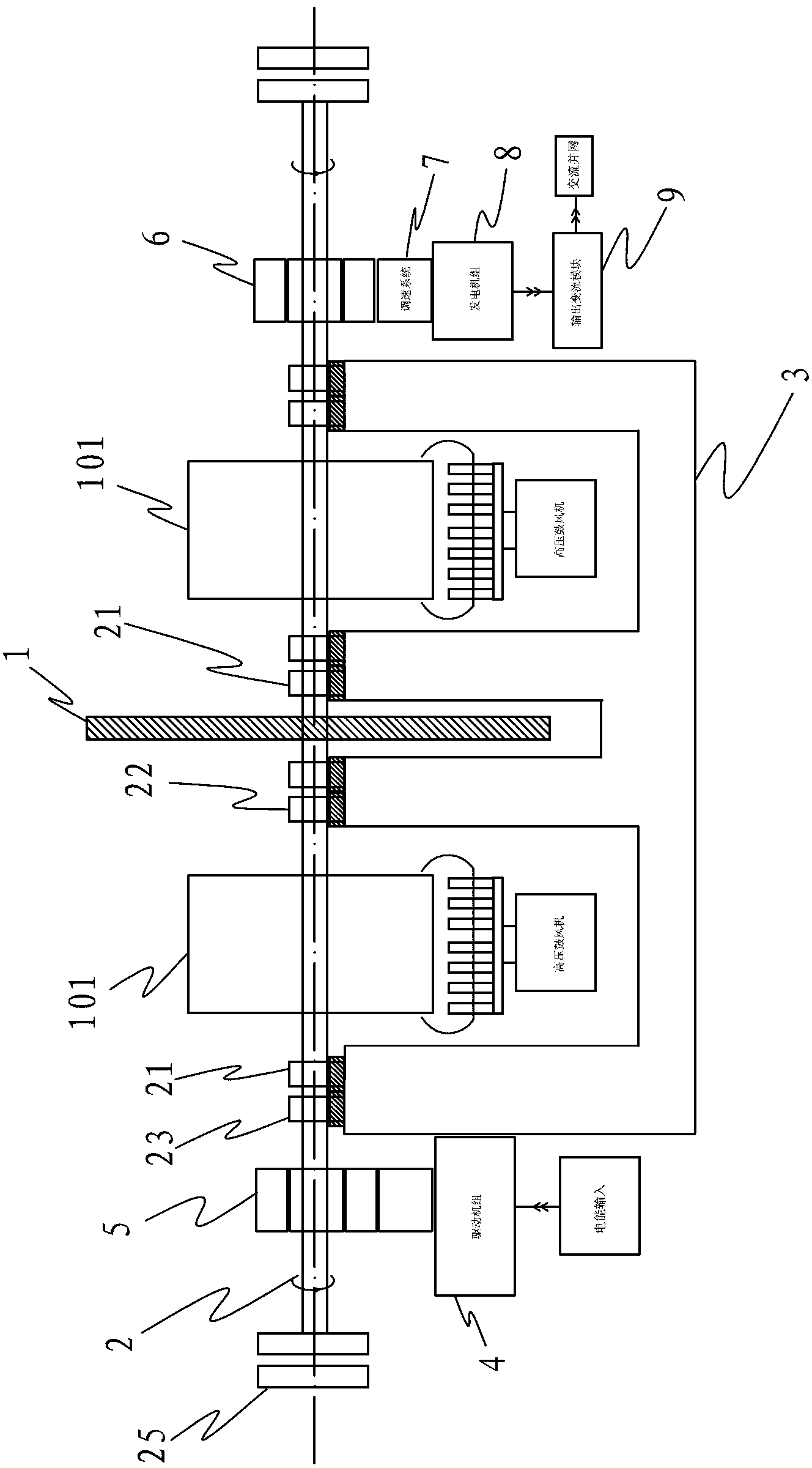

[0117] refer to figure 1, the first embodiment of the present invention includes a base 3, a rotating shaft 2 is arranged on the base 3, a heavy-duty flywheel 1 is arranged in the middle of the rotating shaft 2, and a plurality of discrete air-cushion buoys 101 and magnetic levitation are arranged on the rotating shaft 2 of this embodiment The buoys 102, the air cushion buoys 101 and the magnetic levitation buoys 102 are respectively symmetrically distributed around the heavy flywheel 1. A high-pressure blower is arranged below the air-cushion buoy 101, which suspends the air-cushion buoy 101 by blowing high-pressure gas to provide upward buoyancy for the rotating shaft 2; The electromagnet array or the permanent magnet array, the electromagnet array is arranged in the buoy seat, after the electromagnet array is energized, it generates magnetic force to make the magnetic levitation buoy 102 float, and provides upward buoyancy for the rotating shaft 2 . During normal use, pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com