Flame-retardant deodorizing filter

A filter and flame retardant technology, which is applied in the field of flame retardant deodorization filters, can solve the problems of inability to obtain satisfactory ozone performance, shedding of activated carbon particles, and inability to obtain sufficient flame retardancy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

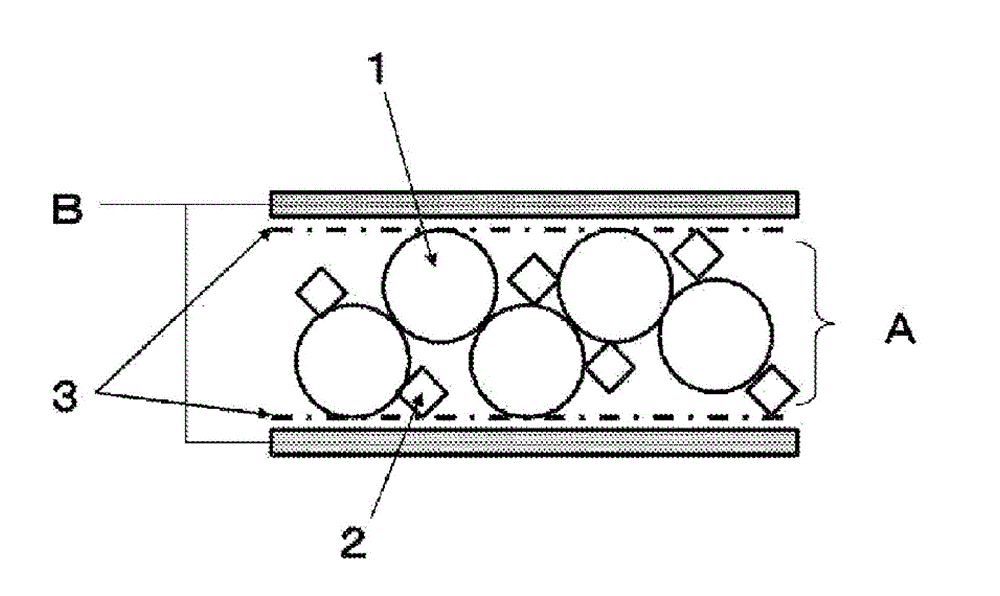

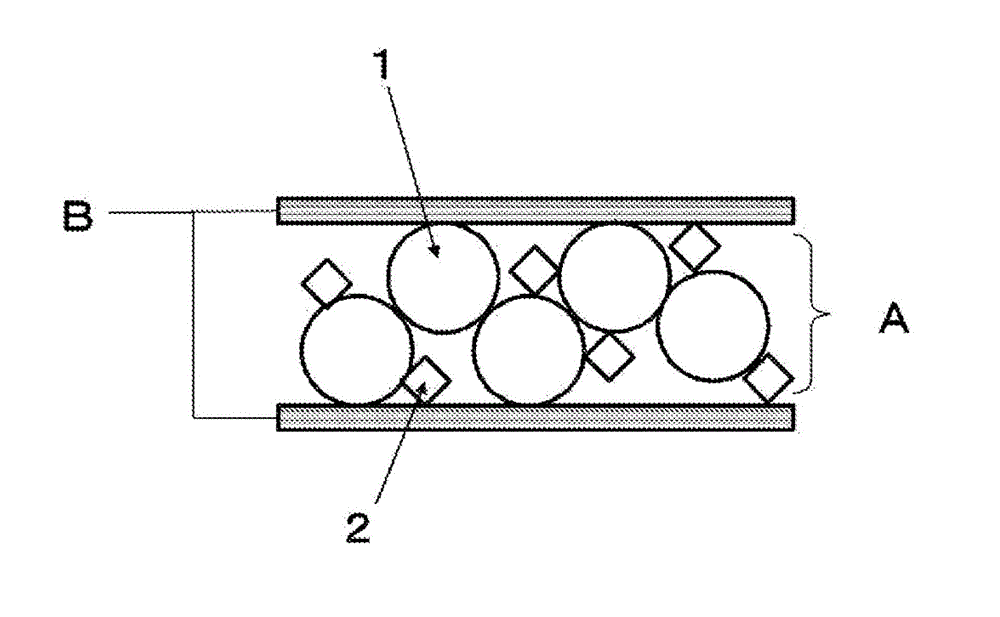

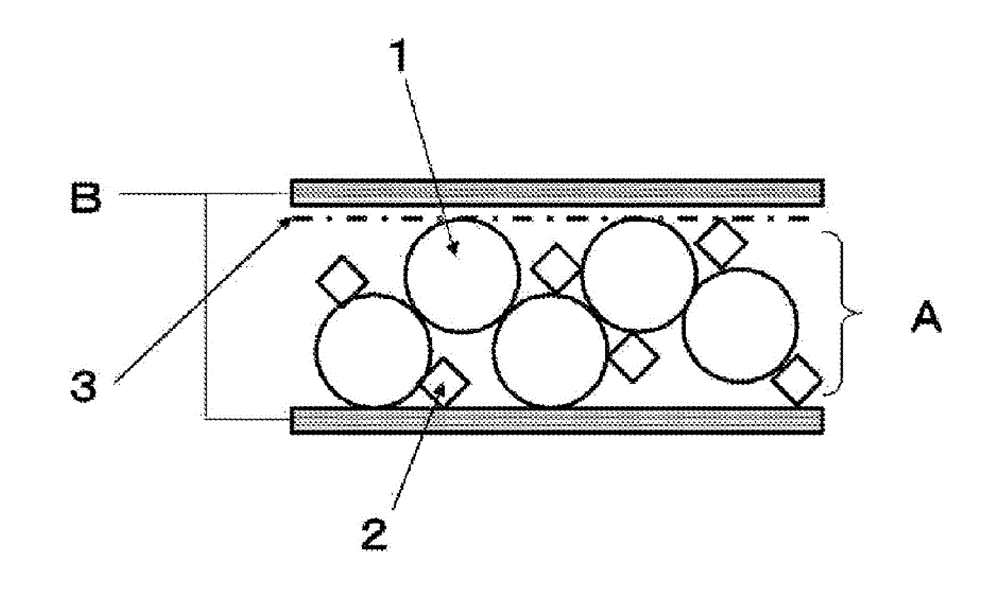

Image

Examples

Embodiment 1-1

[0093] On the cover material (A2) prepared in cover material preparation 2, disperse 250g / m 2 Activated carbon particles (average particle size 500μm) with 2.5g / m 2 A mixture of thermoplastic resin adhesive particles (average particle size 20 μm, polyethylene resin) forms an activated carbon layer, and after stacking the covering material (A2) on the activated carbon layer, it is inserted into the middle of an iron plate heated to 140°C for 1 minute. Pressing, the activated carbon layer is adhered to the thermoplastic resin adhesive particles to make a filter. At this time, the mass per unit area of the filter is 340.5g / m 2 .

Embodiment 1-2

[0095] On the cover material (A3) prepared in cover material preparation 2, disperse 250g / m 2 Activated carbon particles (average particle size 500μm) with 12.5g / m 2 A mixture of thermoplastic resin adhesive particles (average particle size 20 μm, polyethylene resin) forms an activated carbon layer. After stacking the covering material (A3) on the activated carbon layer, insert it into the middle of an iron plate heated to 140°C for 1 minute. Pressing, the activated carbon layer is adhered to the thermoplastic resin adhesive particles to make a filter. At this time, the mass per unit area of the filter is 350.5g / m 2 .

Embodiment 1-3

[0097] On the cover material (A4) prepared in cover material preparation 2, disperse 250g / m 2 Activated carbon particles (average particle size 500μm) with 12.5g / m 2 A mixture of thermoplastic resin adhesive particles (average particle size 20 μm, polyethylene resin) forms an activated carbon layer, and after stacking the covering material (A4) on the activated carbon layer, it is inserted into the middle of an iron plate heated to 140°C for 1 minute. Pressing, the activated carbon layer is adhered to the thermoplastic resin adhesive particles to make a filter. At this time, the mass per unit area of the filter is 368.5g / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com