Thermosetting Resin Filling Material

A filling material and thermosetting technology, which is applied in the manufacture of printed circuits, electrical components, and printed circuits. It can solve the problems of difficulty in forming flat plating, poor patterning, and influence, and achieves suppression of deterioration over time and excellent shape retention. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

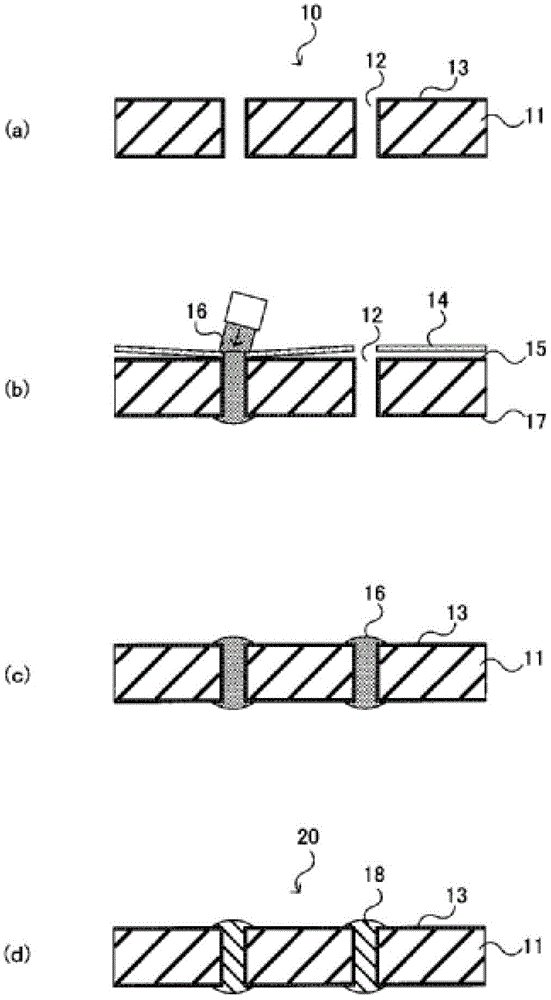

Method used

Image

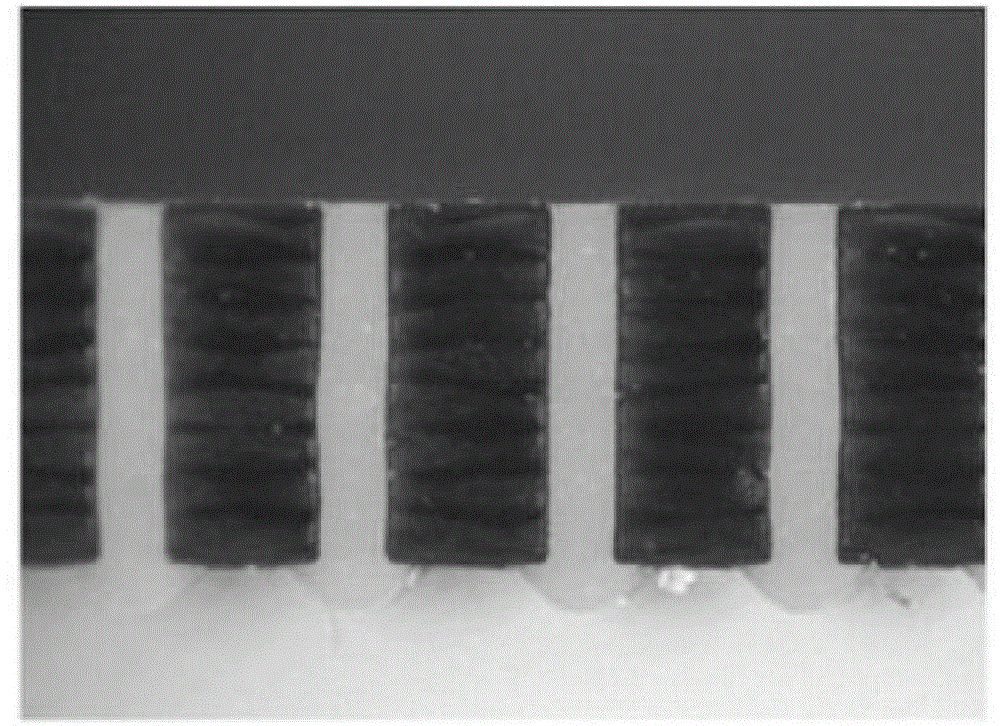

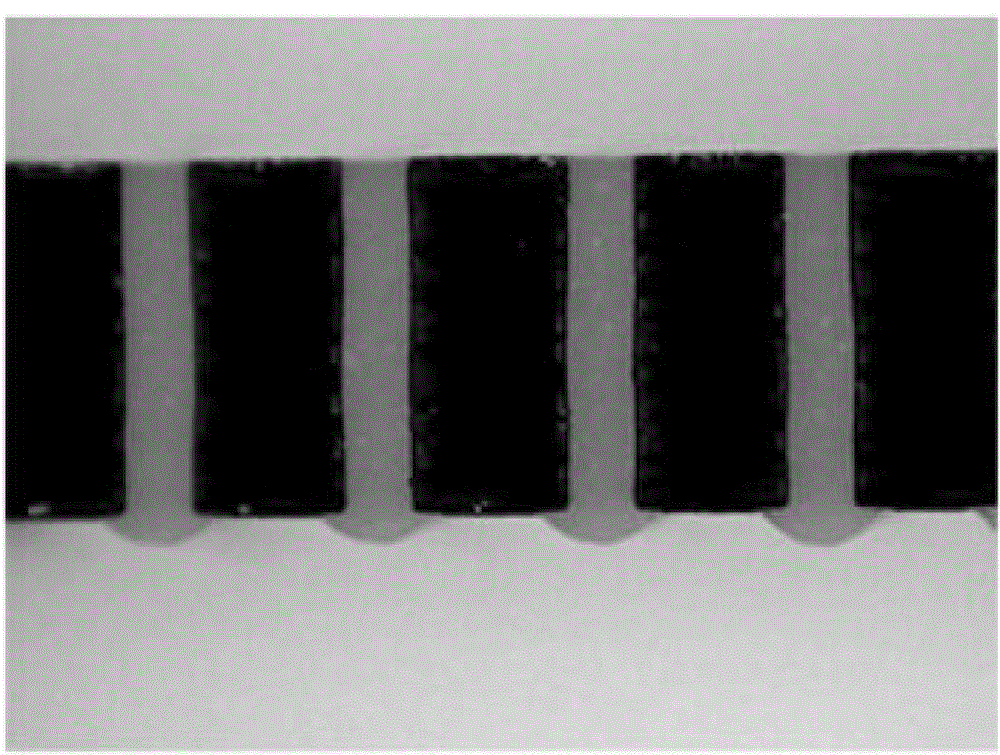

Examples

Embodiment

[0064] Hereinafter, the present embodiment will be specifically described by showing examples and comparative examples. It should be noted that the following "parts" and "%" are all quality standards unless otherwise specified.

[0065] (preparation of paste)

[0066] After the components shown in Table 1 were premixed with a mixer in their respective compounding ratios (parts by mass), they were dispersed with a three-roll mill to prepare thermosetting resin fillers of Examples 1 to 8 and Comparative Examples 1 to 3. paste.

[0067] [Table 1]

[0068]

[0069] *1: 828 (manufactured by Mitsubishi Chemical Corporation)

[0070] *2: 807 (manufactured by Mitsubishi Chemical Corporation)

[0071] *3: p-aminophenol type epoxy resin jER-630 (manufactured by Mitsubishi Chemical Corporation)

[0072] *4: 2MZ-A (manufactured by Shikoku Chemicals Co., Ltd.)

[0073] *5: SO-C5 (manufactured by ADMATECHS CO.,LTD.)

[0074] *6: SOFTON1800 (manufactured by BIHOKUFUNKAKOGYOCO.,LTD....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thixotropic index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com