Automatic culture device

A culture device and automatic technology, applied in the direction of tissue cell/virus culture device, enzymology/microbiology device, biochemical equipment and method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

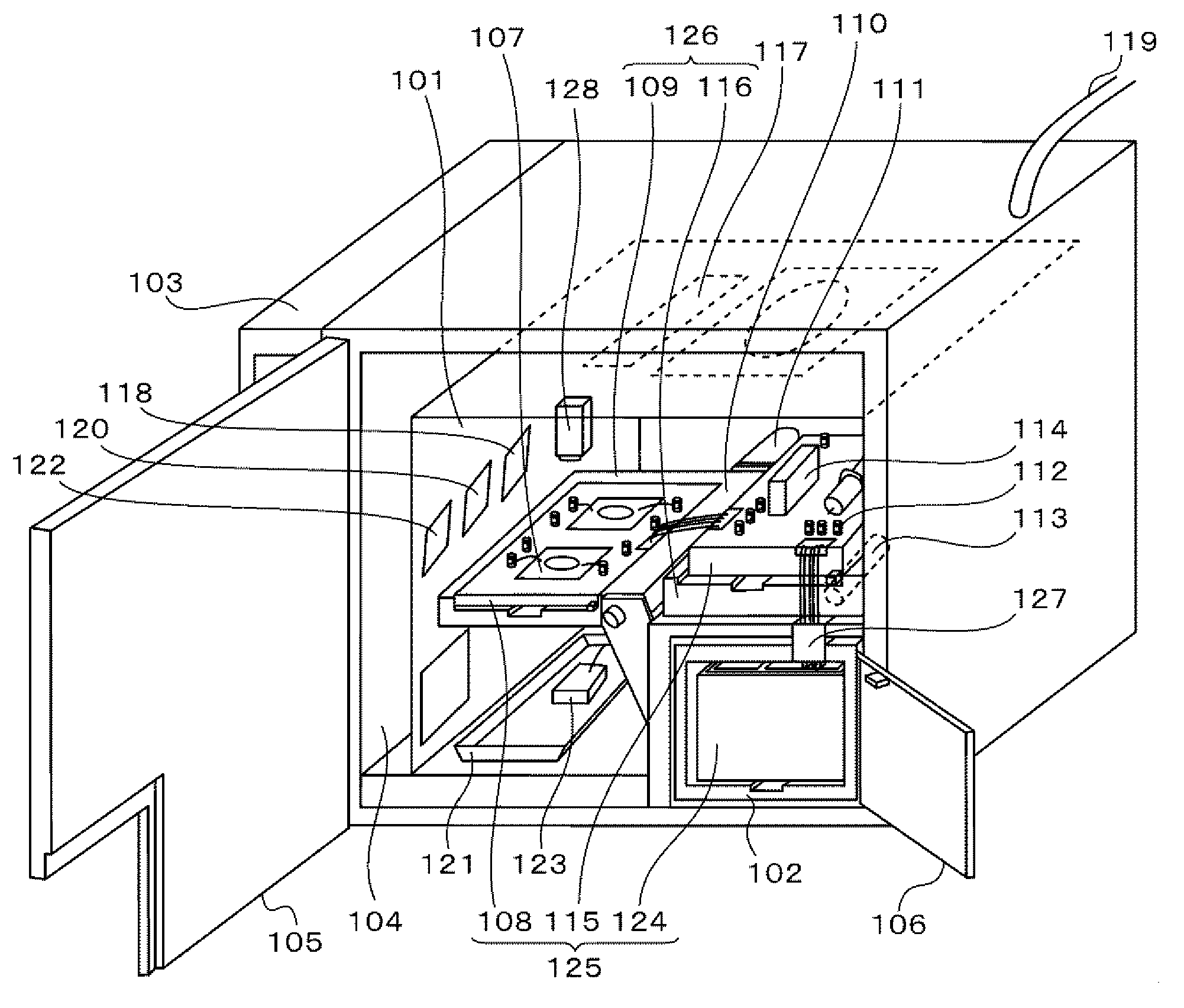

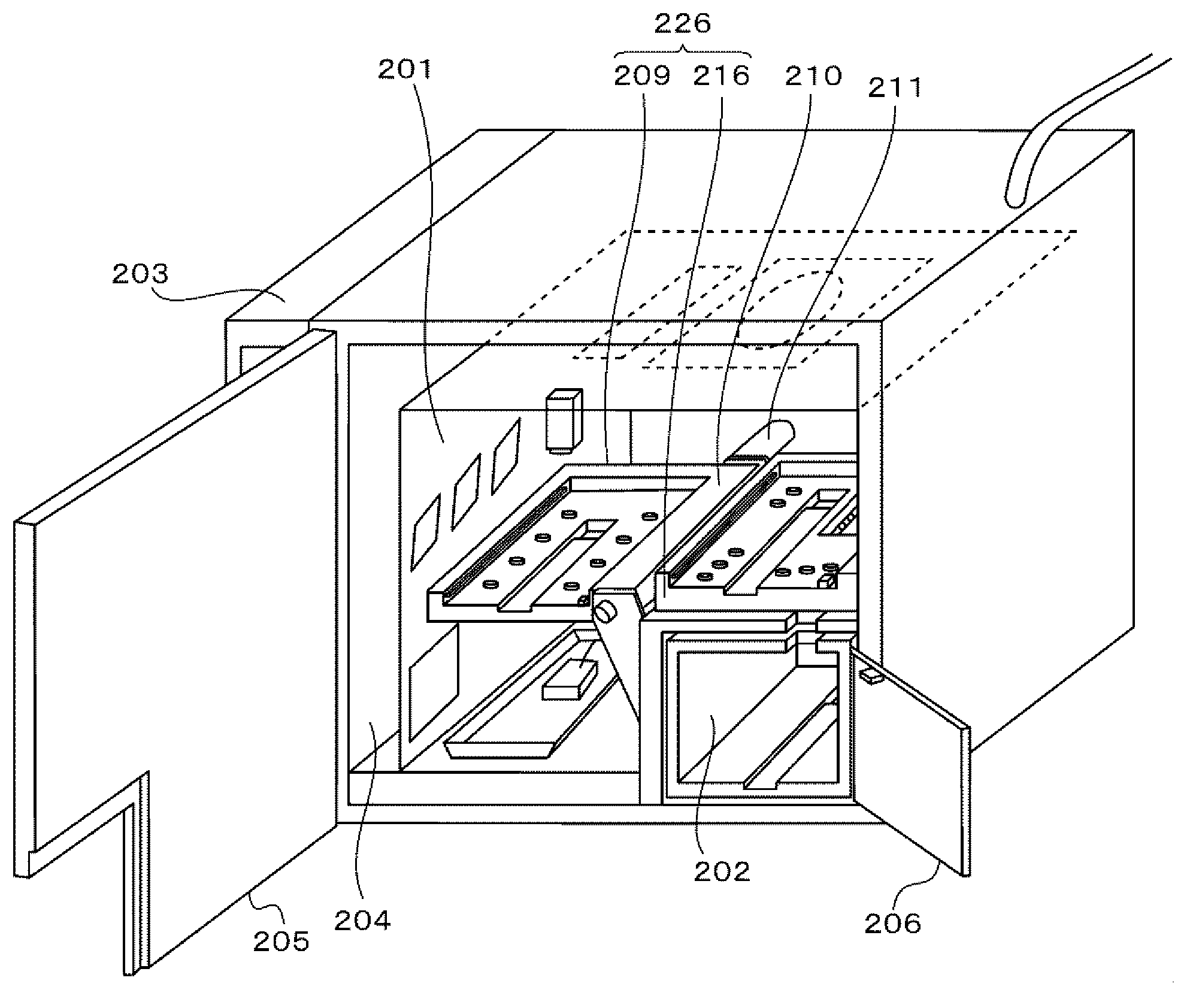

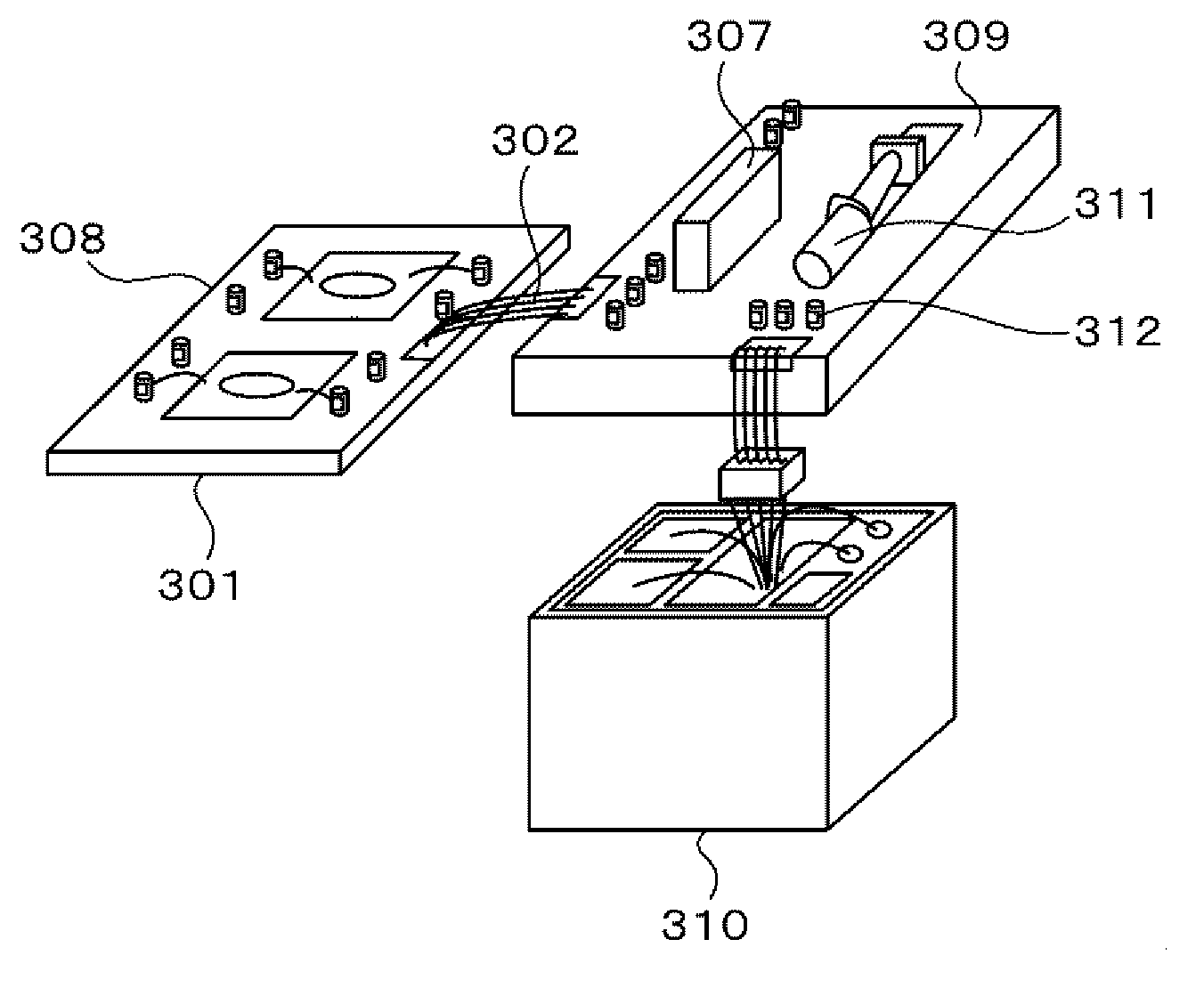

[0053] figure 1 The whole structure of the automatic culture apparatus provided with the flow path part is shown. figure 2 It shows the overall structure of the automatic culture device before installing the flow path. Figure 3A , Figure 3B , Figure 3C The overall state of the channel part installed in the automatic culture device, the part related to culture in the channel part, and the base unit holding the part related to culture in the channel part are respectively shown. The flow path shown here is an example of a structure in the case of culturing two box-type closed culture containers.

[0054] Figure 4 The structure of the box-type closed culture container of the first embodiment is shown. Figure 5 It shows a state in which a diffuser is installed in the culture space of the modified box-shaped closed culture container of the first embodiment, and the diffuser can promote cell diffusion when the cell suspension flows into the culture space to uniformly inocu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com