System and method for trapping carbon dioxide from flue gases in multi-stage manner

A technology of carbon dioxide and flue gas, applied in chemical instruments and methods, separation methods, separation of dispersed particles, etc., can solve the problems of low separation selectivity and low purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] Embodiments will now be described with reference to the drawings.

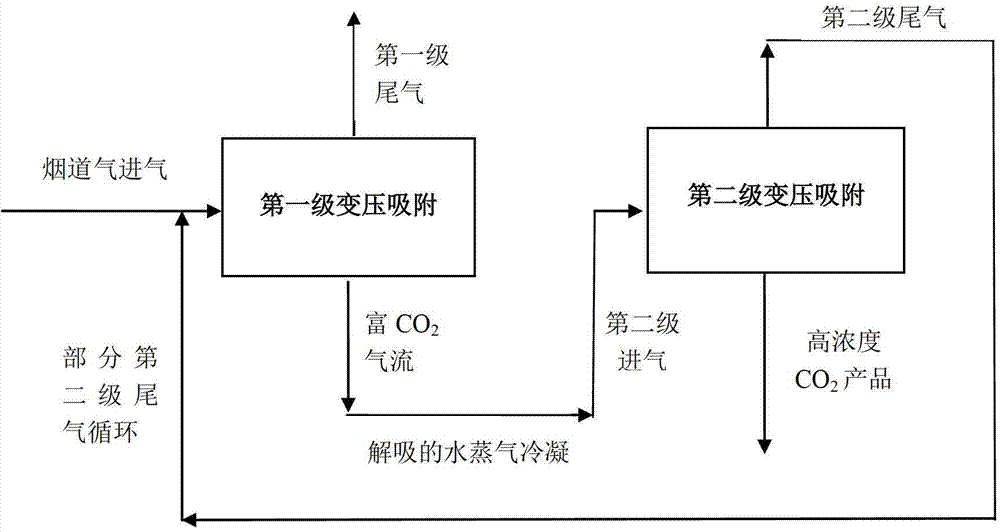

[0075] The introduction of the two-stage pressure swing adsorption process used in the present invention can be found in figure 1 .

[0076] The parameters of the first-stage adsorption device, the operating parameters and the specifications of the adsorbents in the first and second-stage VSA are shown in Table 1. Among them, the first-stage VSA uses activated carbon as the hydrophobic adsorbent, and the second-stage VSA uses 13X zeolite molecular sieve as the active agent.

[0077] Table 1

[0078]

[0079] The operation steps and results of the first stage vacuum pressure swing adsorption are described as follows:

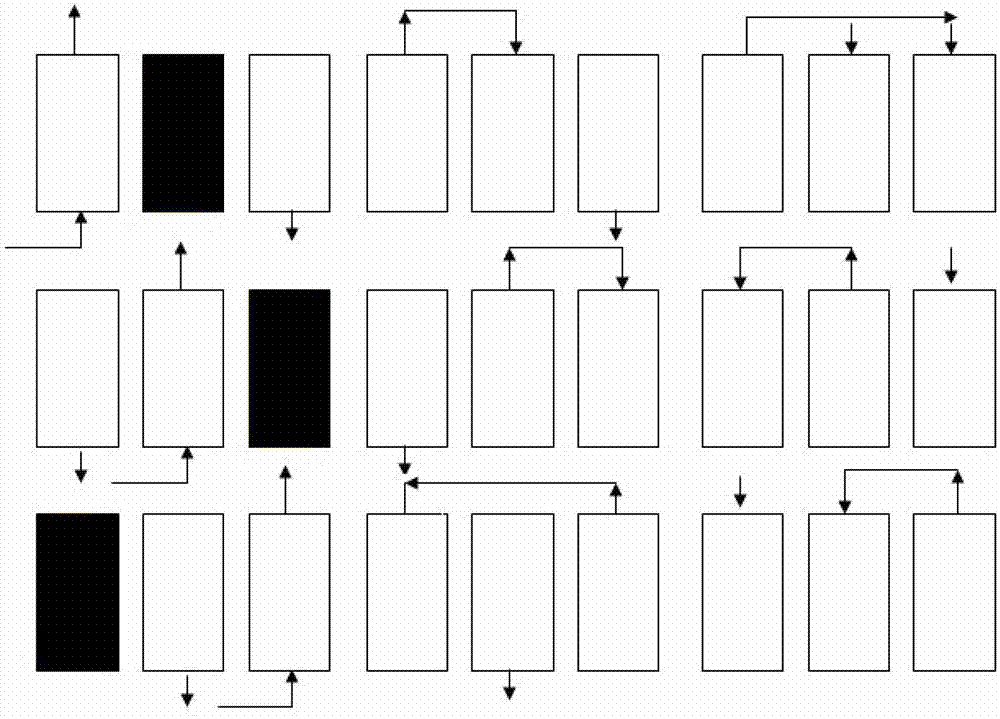

[0080] The first stage VSA uses a three-bed 9-step cycle, see figure 2 . The detailed operation process is as follows:

[0081] (1) In the first step, the No. 1 bed is subjected to the air intake step, and the No. 3 bed is subjected to the desorption step. Bed No. 2 is bye and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com