Electrostatic flocked product with stable impedance values

An electrostatic flocking, impedance value technology, applied in the direction of layered products, metal layered products, synthetic resin layered products, etc., can solve the problems of height limitations, high overall impedance, poor impedance uniformity, etc., to ensure the strength. And flexibility, improve bonding performance, increase the effect of overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

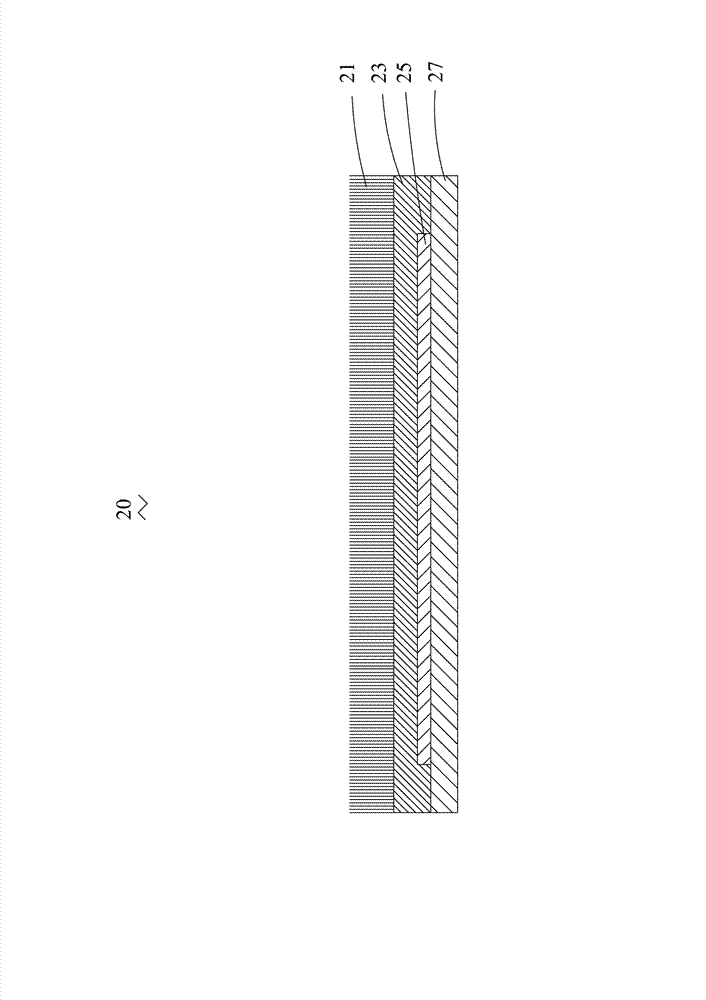

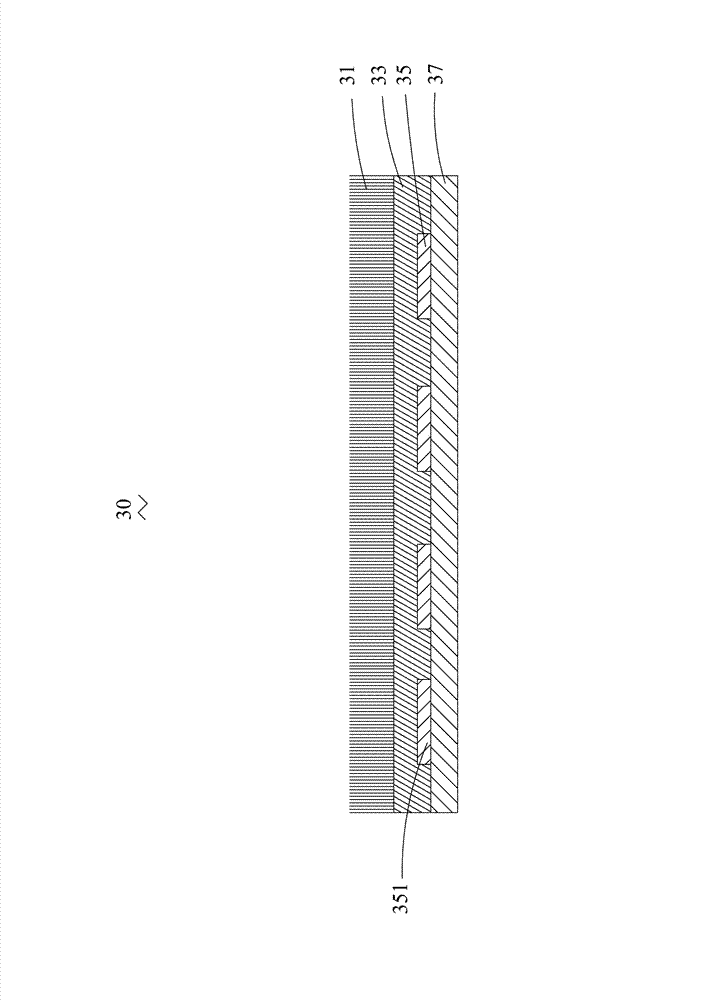

[0019] see Figure 1 to Figure 4 , the invention provides an electrostatic flocking product with stable impedance value.

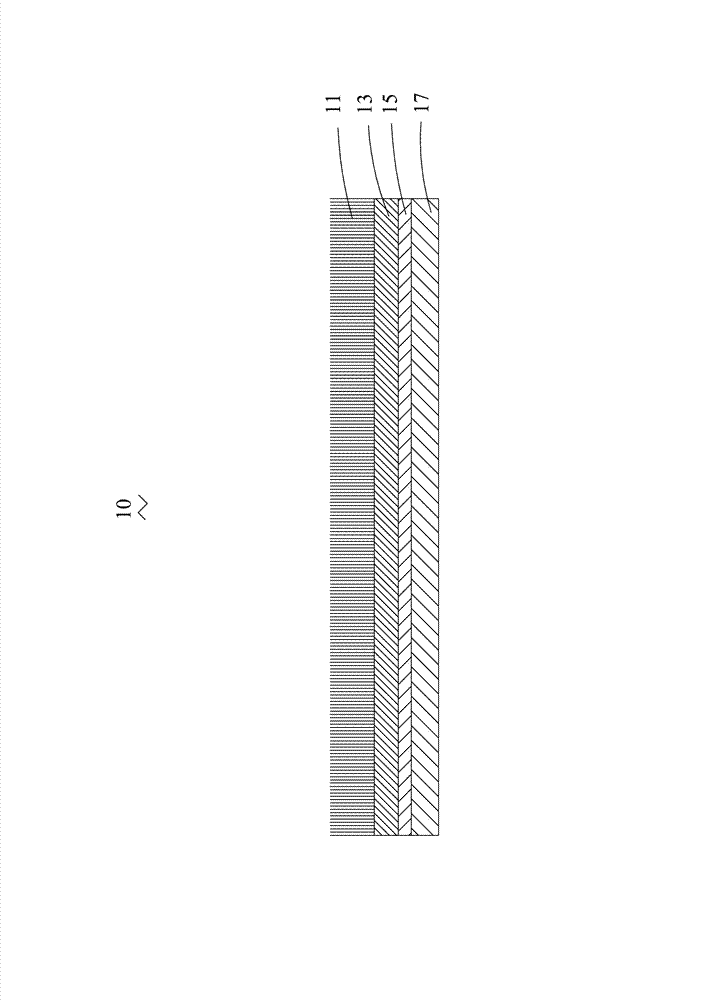

[0020] Such as Figure 1 Shown is an electrostatic flocking product 10 with stable impedance according to Embodiment 1 of the present invention, including a flocking layer 11 , an adhesive layer 13 , a conductive layer 15 and an insulating layer 17 .

[0021] The flocking layer 11, the adhesive layer 13, the conductive layer 15 and the insulating layer 17 are sequentially stacked and closely connected to each other. The flocking layer 11 is composed of conductive fibers flocked on the adhesive layer 13 . The conductive layer 15 is made of aluminum. The insulating layer 17 is made of plastic. It can be understood that the conductive layer 15 can be made of other conductive metals or alloys, and the insulating layer 17 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com