Working wheel for road building machine

A technology of road construction machinery and working wheels, which is applied in roads, roads, buildings, etc., can solve the problems of limited compaction range, and achieve the effects of avoiding damage to structures, wide application range, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

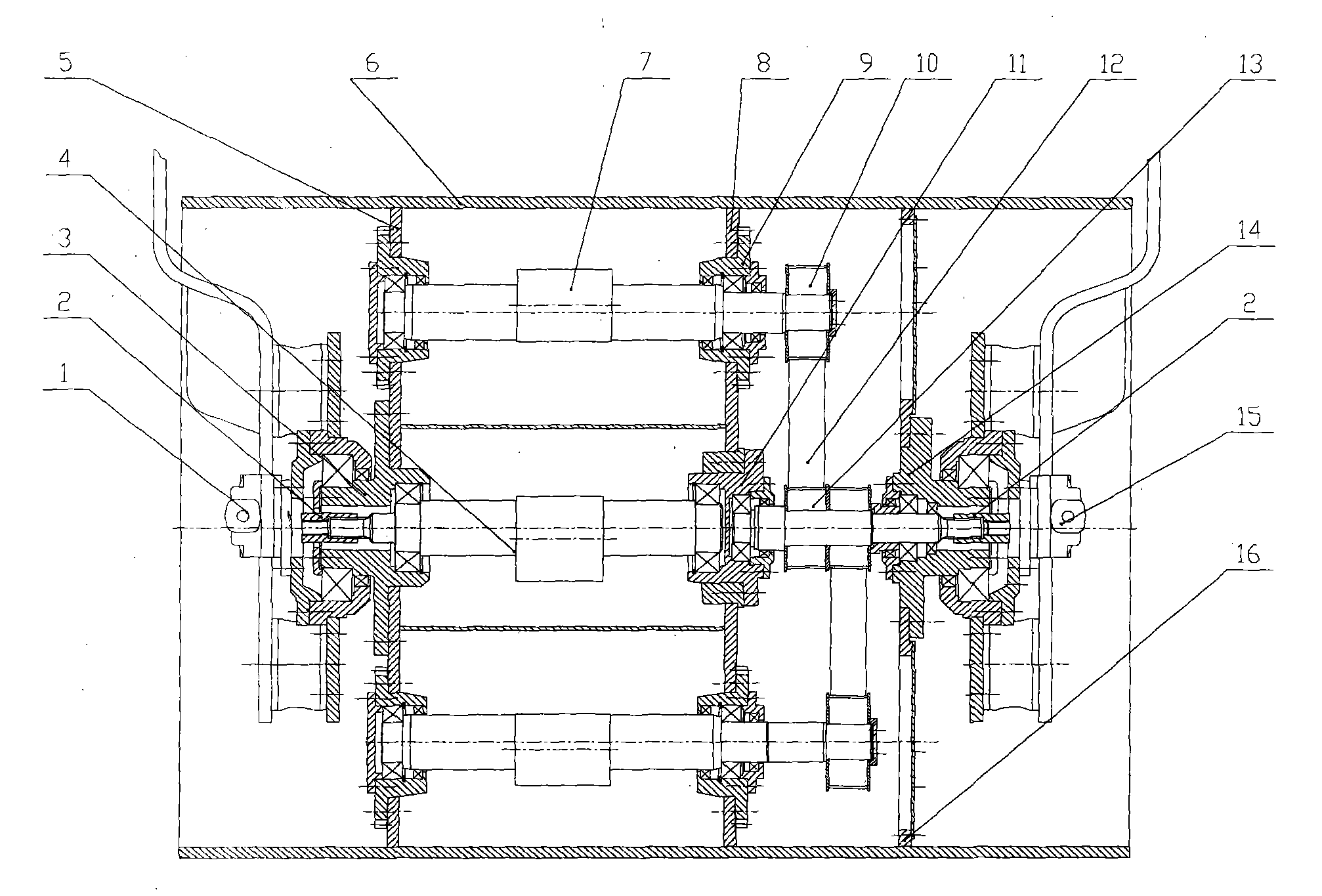

[0021] As shown in the figure; left panel 5, middle panel 8, and right panel 16 are respectively arranged in the working wheel cylinder body 6 of the road construction machinery, and the centers of left panel 5, middle panel 8, and right panel 16 are pre-prepared respectively. Concentric shaft holes are reserved; the left vibration bearing seat 3 is set in the reserved shaft hole in the middle of the left width plate 5, and the bearing is set in the left vibration bearing seat 3, and the middle bearing seat 11 is set in the reserved hole in the middle of the middle width plate 8, and the middle bearing Bearings are set in the reserved shaft holes of the seat 11, the vibration eccentric shaft 4 is set in the bearings of the left width plate 5 and the middle width plate 8, the left vibration motor 1 is set on the left side of the vibration eccentric shaft 4, the left vibration motor 1 and the vibration eccentric shaft The spline connection sleeve 2 is arranged between 4; the bear...

Embodiment 2

[0023] As shown in the figure; two pairs of eccentric shaft holes are symmetrically reserved on both sides of the central shaft hole of the left panel 5 and the middle panel 8, and a bearing seat 9 is arranged in the eccentric shaft hole, and a bearing is arranged in the bearing seat 9, and the left panel 5 and the The oscillating eccentric shaft 7 is set in the bearing of the medium-width plate 8, and the shaft head on the right side of the oscillating eccentric shaft 7 is respectively provided with a driven toothed pulley 10, which corresponds to the pulley of the driving shaft toothed pulley 13 It is provided that a toothed belt 12 is set between the driven toothed pulley 10 and the driving shaft toothed pulley 13 .

Embodiment 3

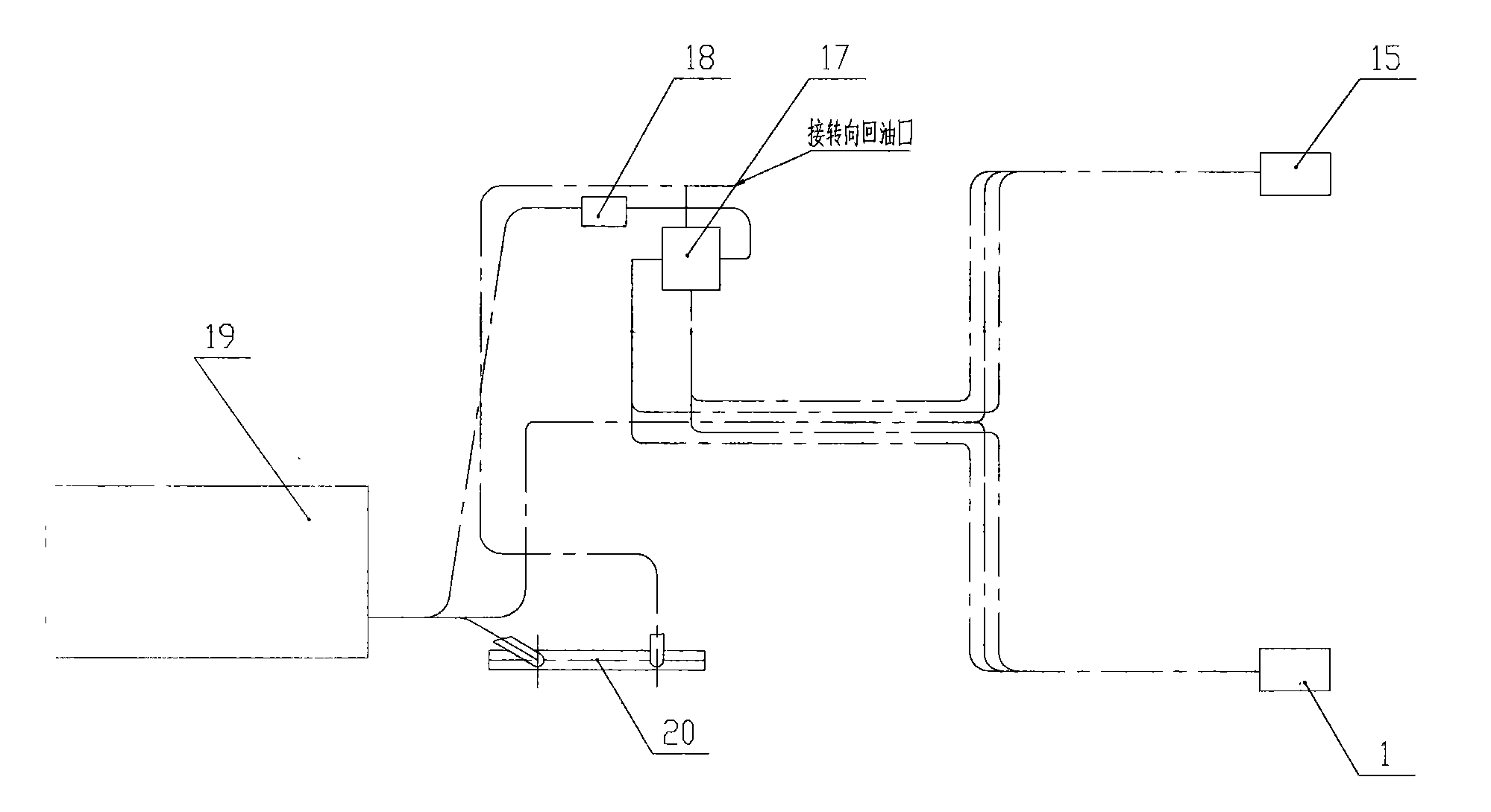

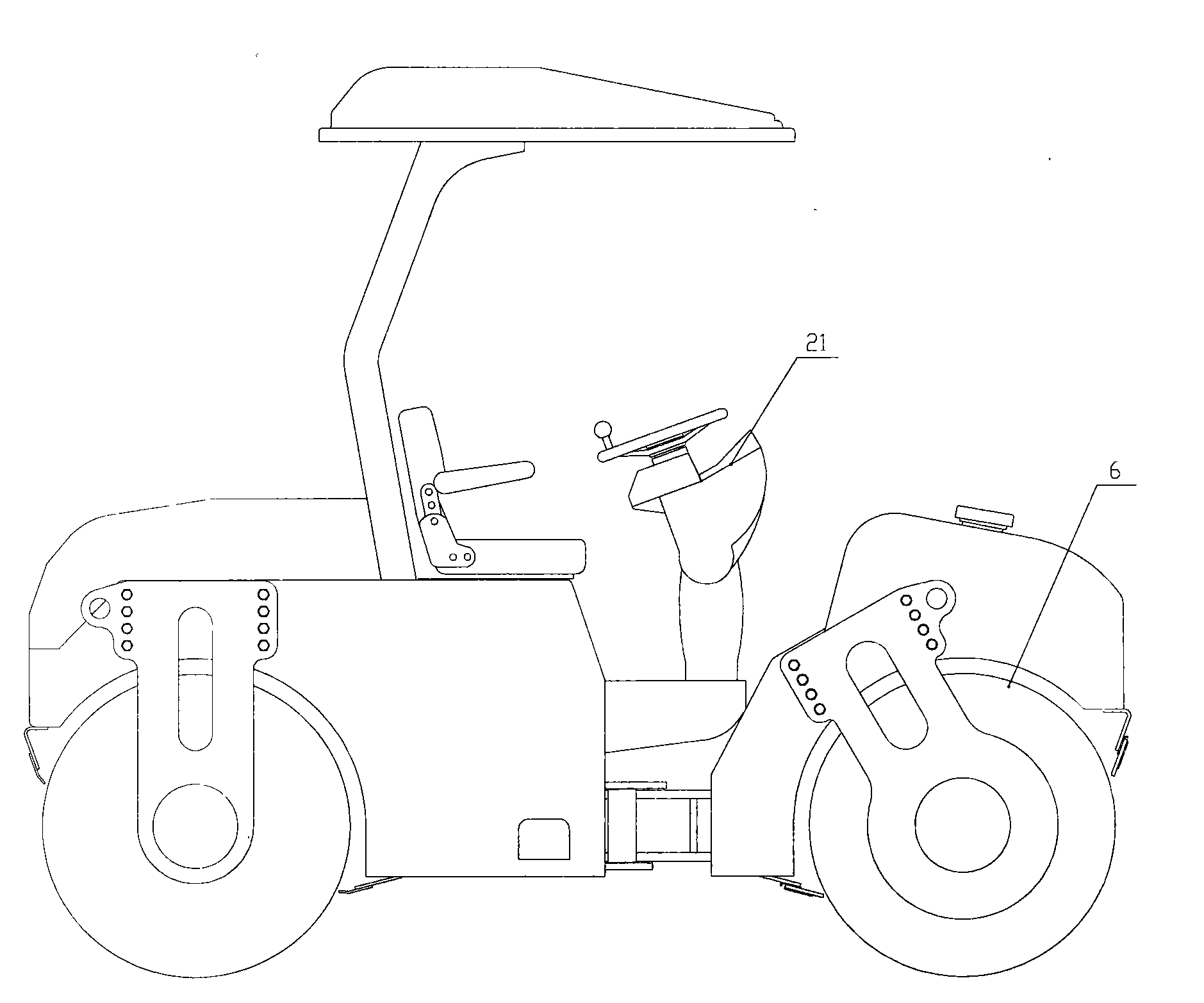

[0025] An electronically controlled instrument panel is installed in the cab of the road construction machinery. An instrument panel 21 is arranged on the electronically controlled instrument panel. A reversing switch is arranged on one side of the instrument panel 21. A control circuit is arranged between the reversing switch and the electromagnetic reversing valve 17. A hydraulic pipeline is arranged between the reversing valve 17 and the hydraulic oil tank 19, a hydraulic pump 18 is arranged between the hydraulic pipelines, and two hydraulic pipelines are arranged on the other side of the electromagnetic reversing valve 17, and one hydraulic pipeline is the electromagnetic reversing valve 17 The hydraulic pipeline with the left vibration motor 1, and the other hydraulic pipeline is the hydraulic pipeline between the electromagnetic reversing valve 17 and the right oscillating motor 15; the oil return pipeline between the hydraulic oil tank 19 and the electromagnetic reversing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com