Anti-clogging type water seal device for coke oven gas conveying pipeline

A technology of water sealing device and coke oven gas, which is applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc. It can solve the problems that the gas cannot be transported safely, the viscous residue of asphalt cannot be smoothly discharged, and it is difficult to clean up. Good environmental benefits and social benefits, avoiding the effect of clogging the drain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

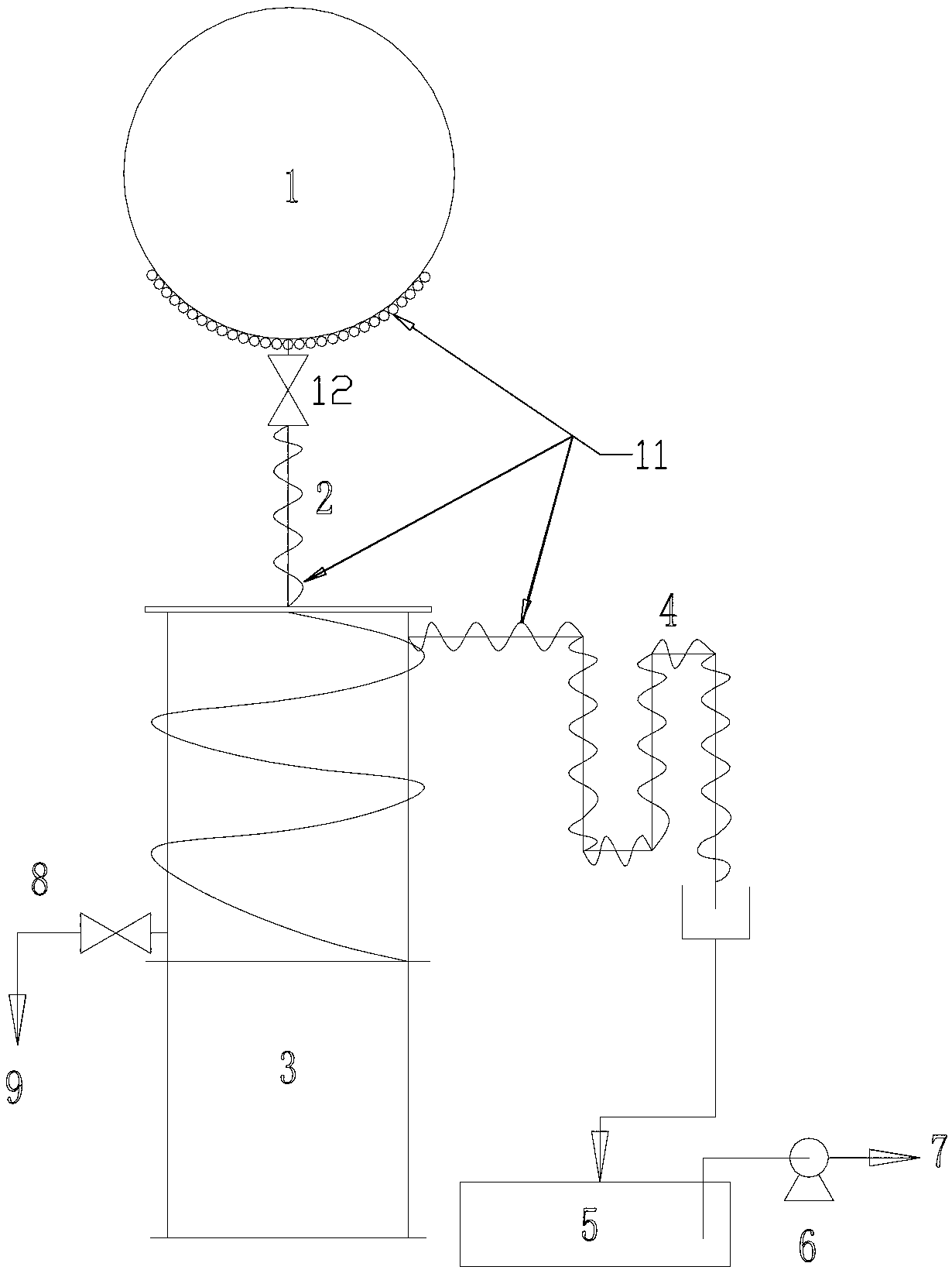

[0024] Such as Figure 1 ~ Figure 3 as shown,

[0025] An anti-blocking water sealing device for coke oven gas pipelines, comprising a gas pipeline 1, an oil drain pipe 2 and a water sealing box 3.

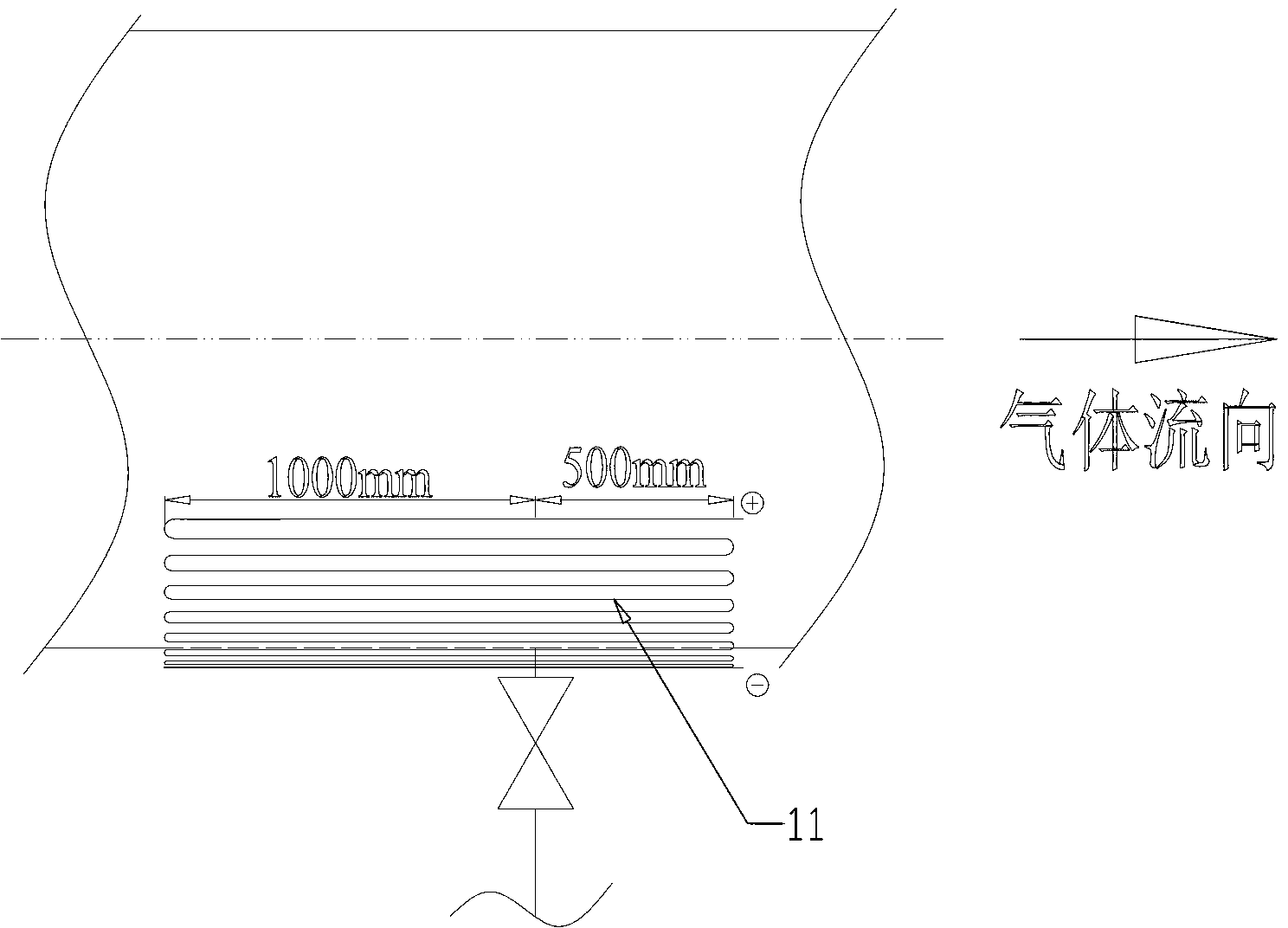

[0026] The water seal box 3 is located directly below the gas pipeline 1, the oil drain pipe 2 is connected to the gas pipeline and the water seal box, and the main valve 12 is connected to the oil drain pipe, and a heating line is arranged on the lower side of the gas pipeline adjacent to the oil drain pipe 11. A heating line 11 is wound on the outside of the oil drain pipe, and a heating line 11 is wound on the outside of the water seal box. At the same time, it is heated to make the residual oil flow out smoothly.

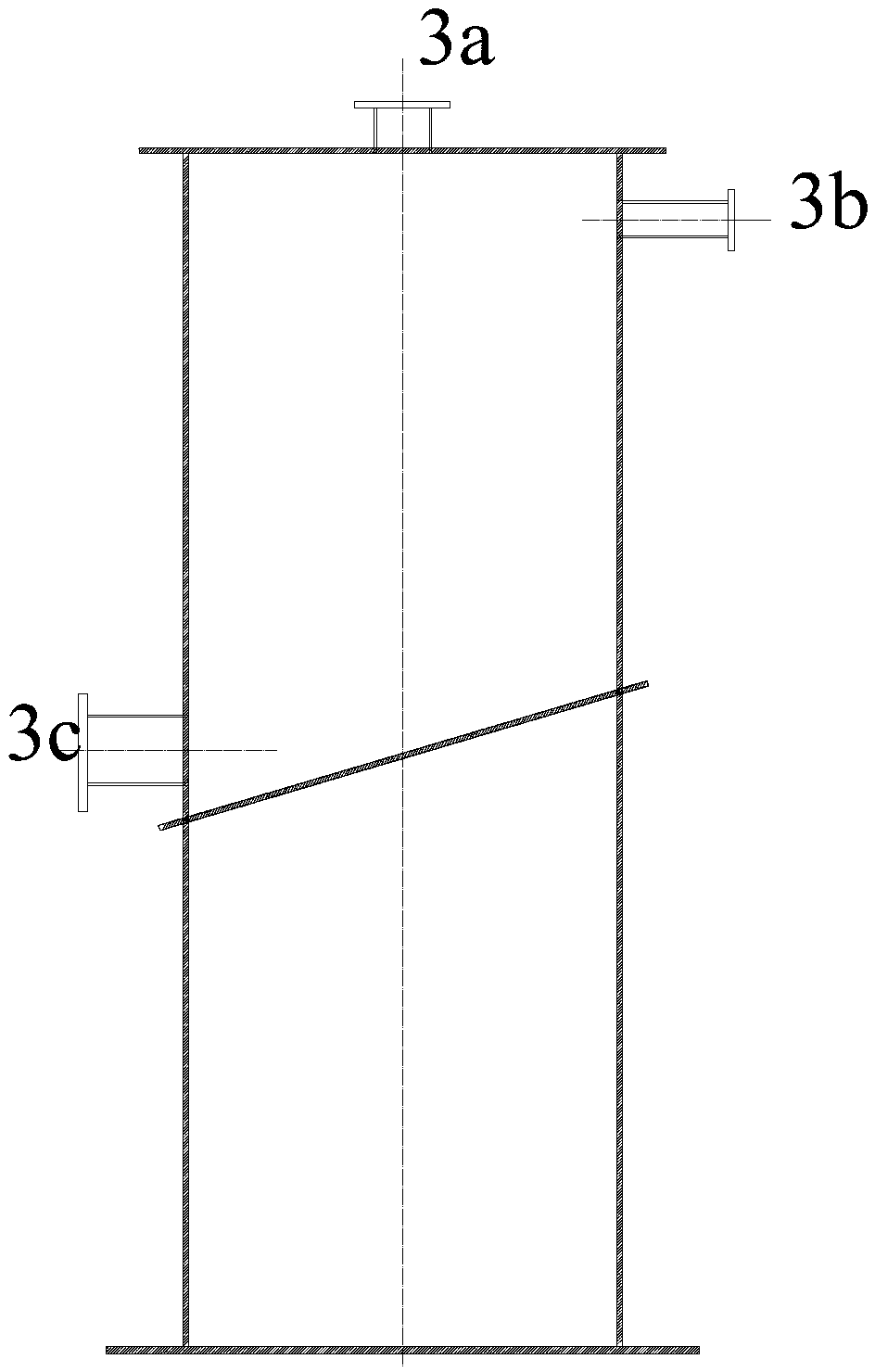

[0027] The upper part of the water seal box 3 is provided with a residual oil inlet 3a and an overflow port 3b. The overflow port is connected to the underground pool 5 through the overflow pipe 4, and a pump 6 pumps the tar in the underground pool to the mechanize...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap