Annular heating furnace large soleplate adopting rolled blank and manufacturing method thereof

A technology of annular heating furnace and manufacturing method, which is applied in lighting and heating equipment, furnace, furnace type and other directions, can solve the problems of inability to meet the working needs of annular heating furnace, the organization structure is not dense, the strength and stability are poor, etc. Defects of microstructure, improvement of mechanical properties, effect of improving work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

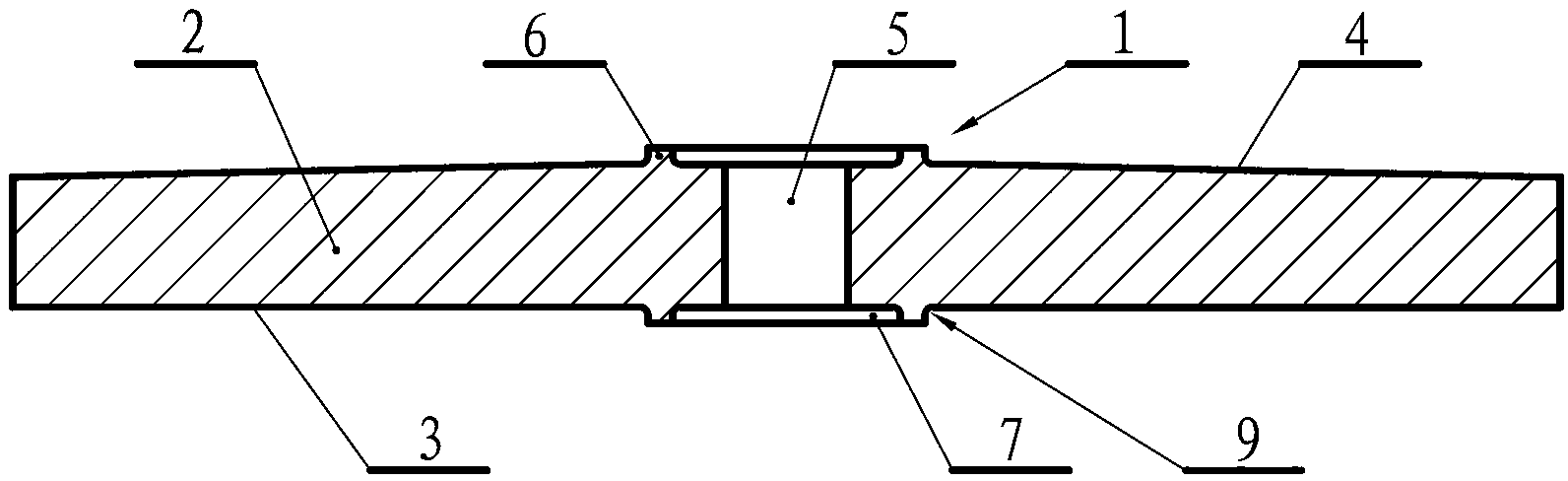

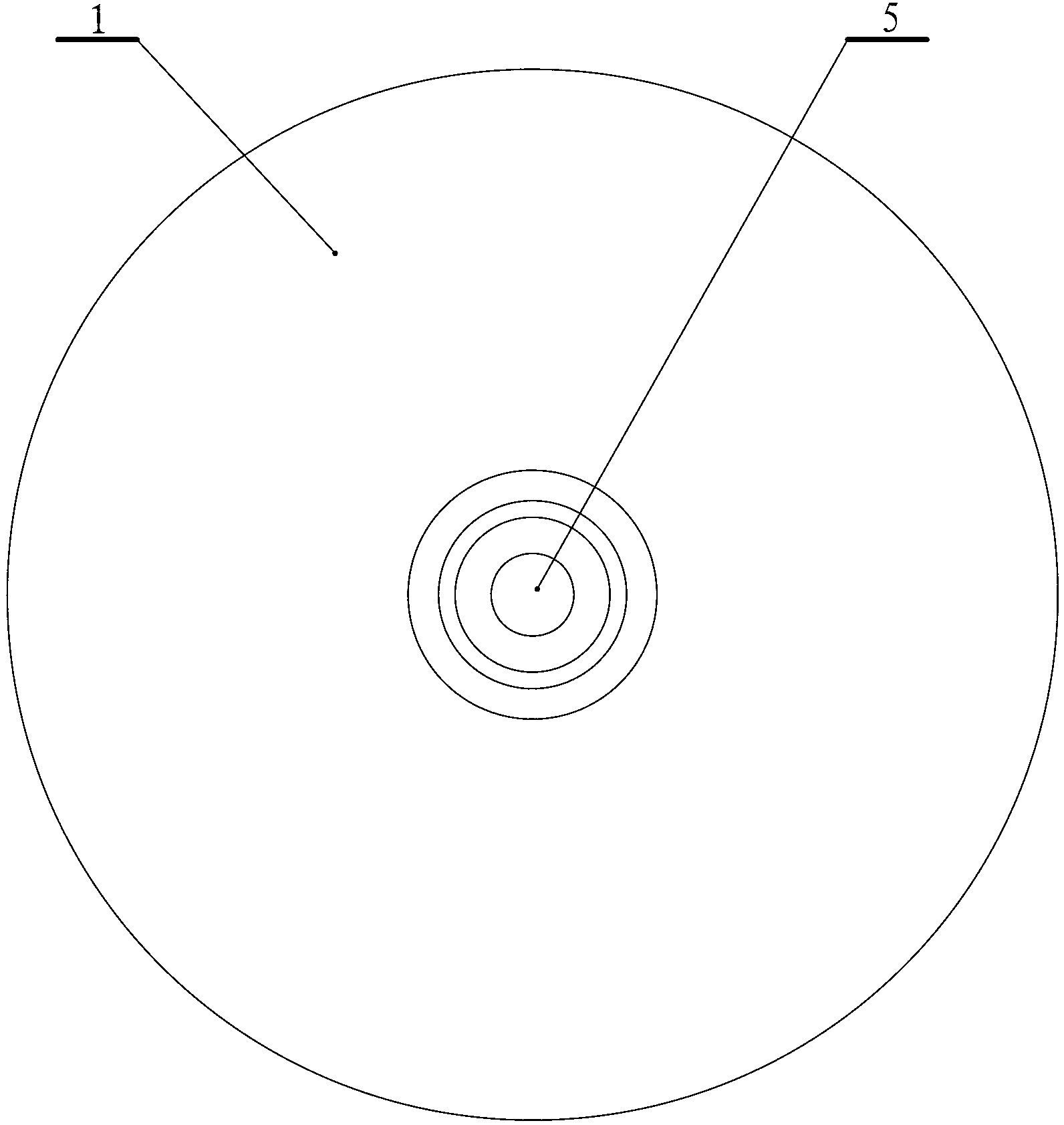

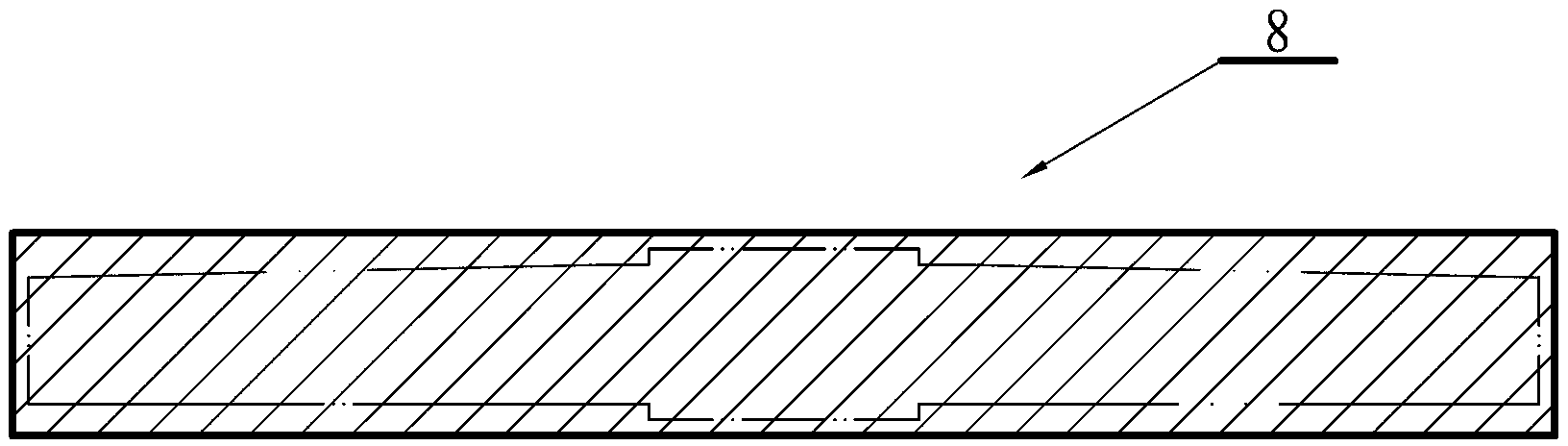

[0031] The large bottom plate of the annular heating furnace adopts rolling blanks. The main body of the large bottom plate is a disc structure. One side of the disc structure is a plane, and the center of the other side of the disc structure is a plane. The surface is coaxial with the large bottom plate, the thickness of the peripheral edge of the disc structure is smaller than the thickness of the center of the disc structure, a central hole is set in the center of the large bottom plate, and circular bosses are respectively set around the central hole on the two sides of the large bottom plate , the ring-shaped boss is coaxial with the central hole, the blank of the large bottom plate is a rolling blank, and the rolling blank is a part of the rolled plate, and the circumferential surface and the opposite two sides of the large bottom plate in the rolling blank are respectively provided with machining allowances. quantity. The thickness of the machining allowance is adapted ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com