Laser binocular vision-based vehicle running deviation online automatic detection system

An automatic detection and vehicle driving technology, which is applied in vehicle testing, machine/structural component testing, measuring devices, etc., can solve the problems of light intensity, low measurement accuracy and efficiency, and failure to meet production requirements, etc. Good implementability, low cost and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

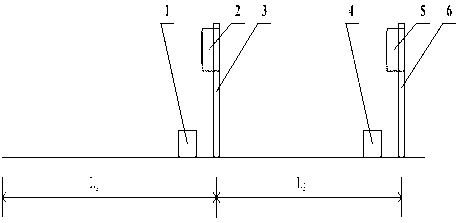

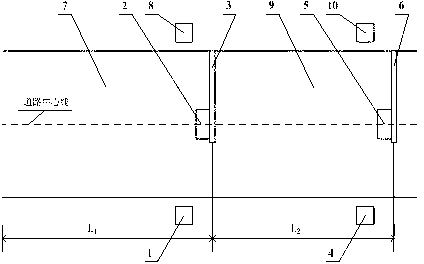

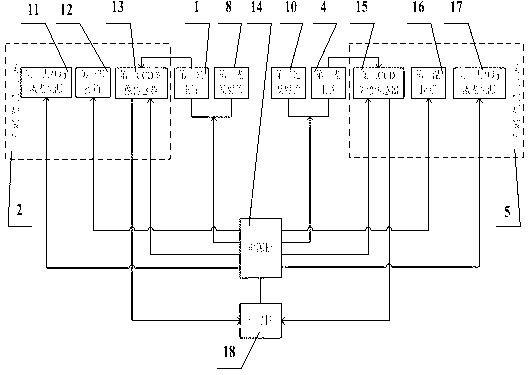

[0049] An online automatic detection system for vehicle deviation based on laser binocular vision. The online automatic detection system such as figure 1 with figure 2 As shown, it includes a power cabinet 14, a computer 18, a first L-shaped frame 3, a second L-shaped frame 6, a first detection device 2, a second detection device 5, a first photoelectric switch, a second photoelectric switch and a detection area.

[0050] The detection area is composed of a test preparation area 7 and a test area 9 .

[0051] Correspondingly fixed with the first L-shaped frame 3 and the second L-shaped frame 6 at the terminal point of the test preparation area 7 and the terminal point of the test area 9, equidistant on the left side of the first L-shaped frame 3 and the second L-shaped frame 6 The ground is correspondingly equipped with a first photoelectric switch and a second photoelectric switch. One end of the upper beam of the first L-shaped frame 3 and the second L-shaped frame 6 is ...

Embodiment 2

[0085] An online automatic detection system for vehicle deviation based on laser binocular vision. Except the tested vehicle, the large field of view laser light source and the technical parameters of the test, the rest are the same as in Embodiment 1.

[0086] The length L of the test preparation area 7 described in the present embodiment 1 is 80m, the length L of the test area 9 2 is 100m; the vehicle under test is a bus, and an optical measurement mark is placed on the top of the bus under test before the test.

[0087]The first large field of view laser light source 11 described in this embodiment is composed of 4 to 6 lasers installed in the first temperature control box 12, and the 4 to 6 lasers are evenly installed in an array on the first CCD image sensor 13 around; Each laser is equipped with an infrared filter that only transmits 808nm.

[0088] The test method of this embodiment is: start the online automatic detection system described in this embodiment, and the...

Embodiment 3

[0094] An online automatic detection system for vehicle deviation based on laser binocular vision. Except the tested vehicle, the large field of view laser light source and the technical parameters of the test, the rest are the same as in Embodiment 1.

[0095] The length L of the test preparation area 7 described in the present embodiment 1 is 100m, the length L of the test area 9 2 It is 150m. The vehicle under test is a truck.

[0096] The first large field of view laser light source 11 described in this embodiment is composed of 6 to 10 lasers installed in the first temperature control box 12, and the 6 to 10 lasers are evenly installed in the first CCD image sensor 13 in a ring shape. Around; Each laser is equipped with an infrared filter that only transmits 808nm.

[0097] The test method of this embodiment is: start the online automatic detection system described in this embodiment, and the vehicle running deviation online automatic detection system software in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com