Automatic wireless locating and control system for electric flat carriage

An automatic positioning and control system technology, applied in the direction of two-dimensional position/channel control, etc., can solve problems such as kiln car derailment, accidents, and low efficiency, and achieve the effects of avoiding safety accidents, long transmission distance, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

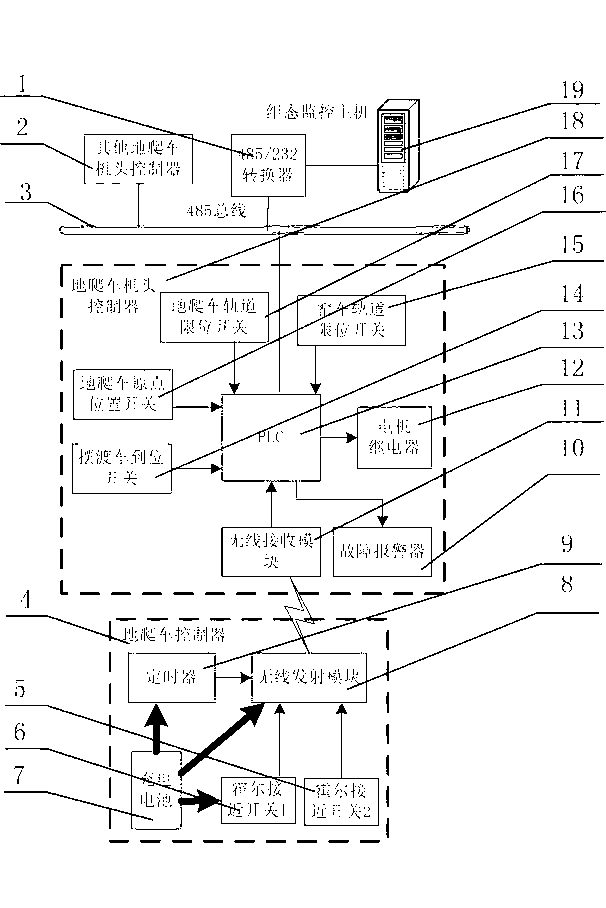

[0027] Local control: When the local climbing car needs to push the kiln car, the operator activates the button of the ground climbing car head controller [18], and the PLC [13] of the ground climbing car head controller [18] drives the motor to pull the ground climbing car in the direction The direction of the kiln car is moved to search for the kiln car. After the local climbing car is positioned to the kiln car, the ground climbing car controller [4] wirelessly transmits the positioning information to the ground climbing car head controller [18], and the PLC [13] of the ground climbing car head controller [18] controls the Motor relay [12], stop traction. At this time, the mechanical head of the ground climbing car is against the positioning groove of the kiln car. After 10 seconds of delay, the PLC [13] of the ground climbing car head controller [18] drives the motor to reverse again, and the traction ground climbing car moves in the reverse direction to push the kiln car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com