Organic light-emitting diode (OLED) panel packaging structure and packaging method

A packaging structure and panel technology, which is applied in the manufacturing of electrical components, electric solid-state devices, semiconductor/solid-state devices, etc., can solve the problems of crushing the connecting electrodes of organic light-emitting diodes, etc., to protect from damage, improve reliability, overcome crack effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

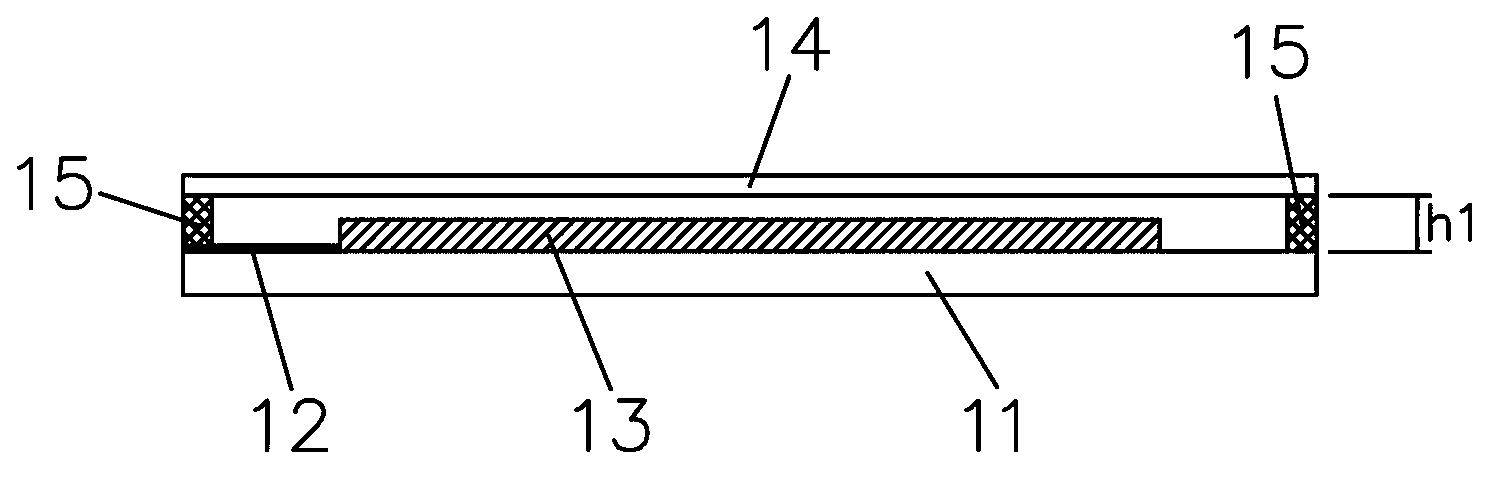

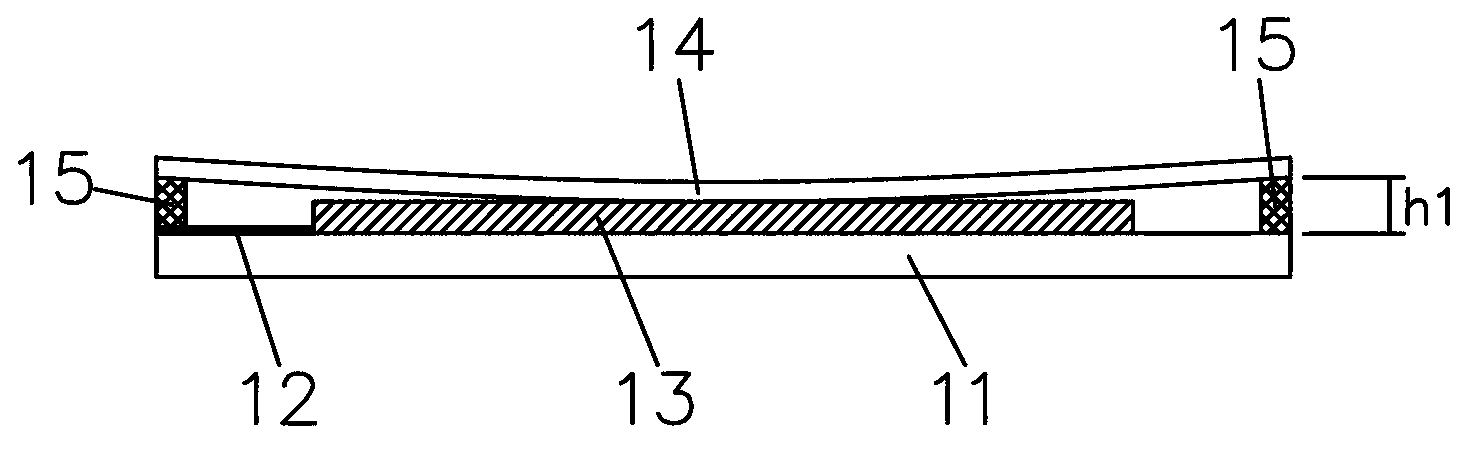

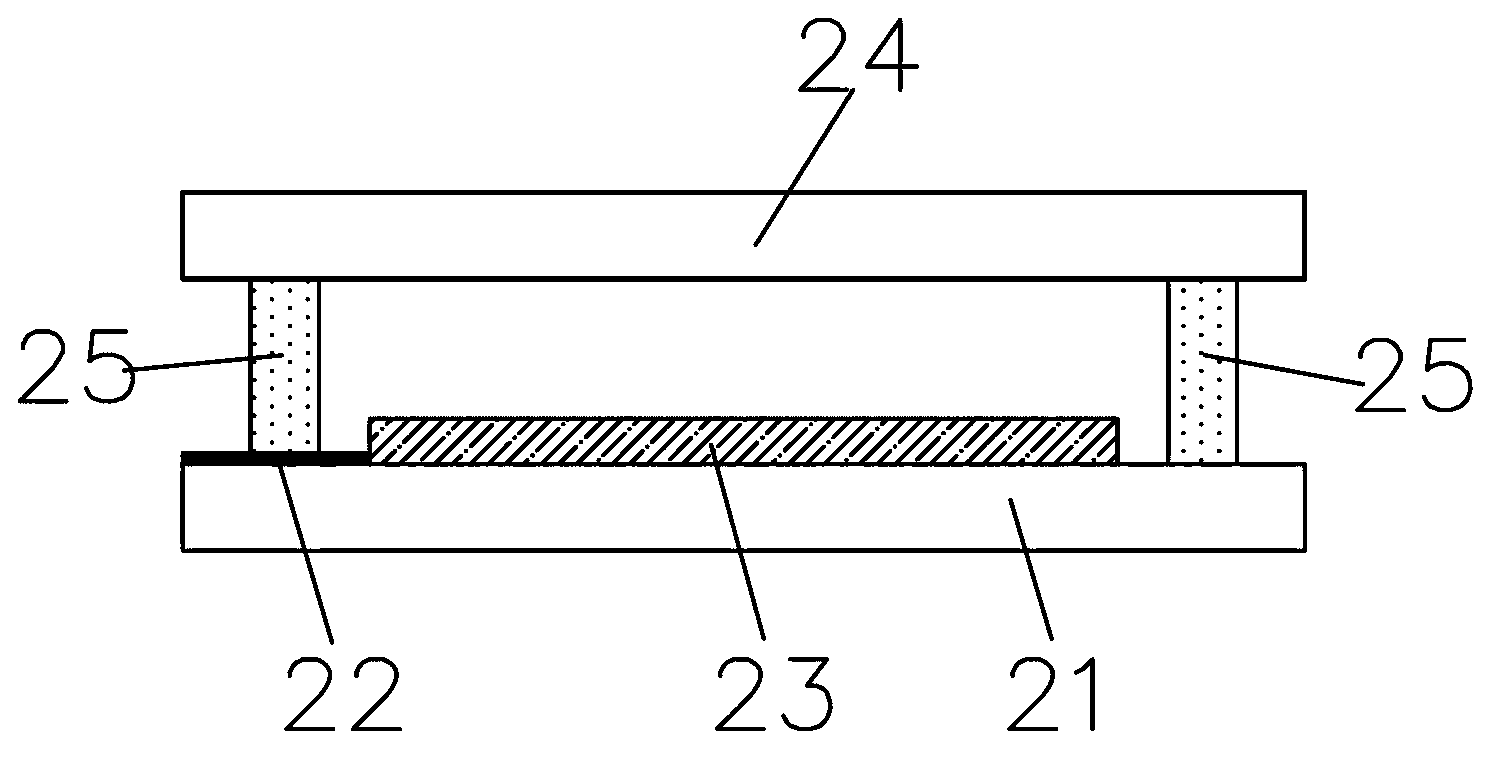

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0023] Such as Figure 2a Shown is a specific embodiment of an OLED panel packaging structure of the present invention, including a substrate 21, a connecting electrode 22, an organic light emitting diode 23 and a cover plate 24, wherein the connecting electrode 22 and the organic light emitting diode 23 are formed on the substrate 21; and The difference of the existing packaging structure is that the packaging structure of this embodiment also includes a glass wall 25 prepared in advance, and the glass wall is in the shape of a closed loop, such as Figure 2b As shown, the shape is consistent with the shape of the edge of the cover plate, and the glass wall is a low softening point glass containing a substance that absorbs specific light; in order to form the protection of the connection electrode 22 and the organic light emitting diode 23, be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com