Rotary road assembly of generalization slip-ring rotor

A slip ring rotor, a universal technology, applied in the direction of electrical components, rotating current collectors, current collectors, etc., can solve the problems of high processing difficulty, processing difficulty, signal interference, etc., to save processing procedures, improve matching accuracy, Guarantee the effect of stable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the accompanying drawings and examples.

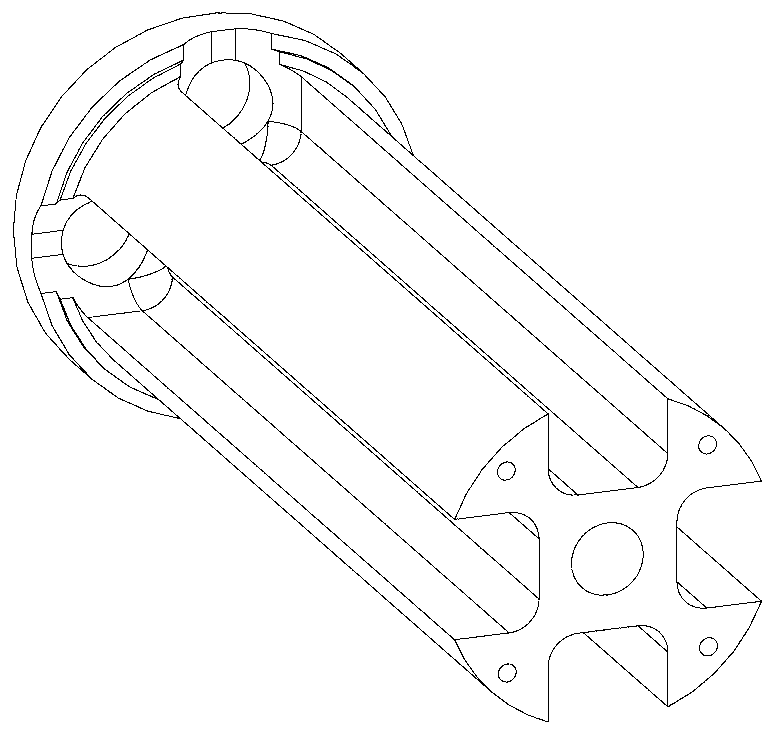

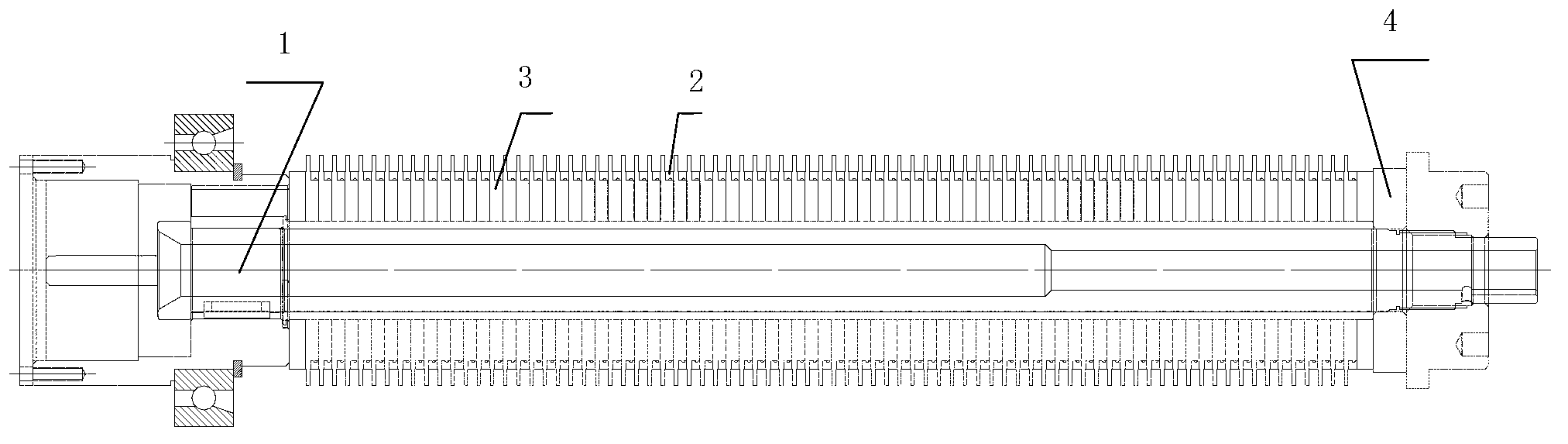

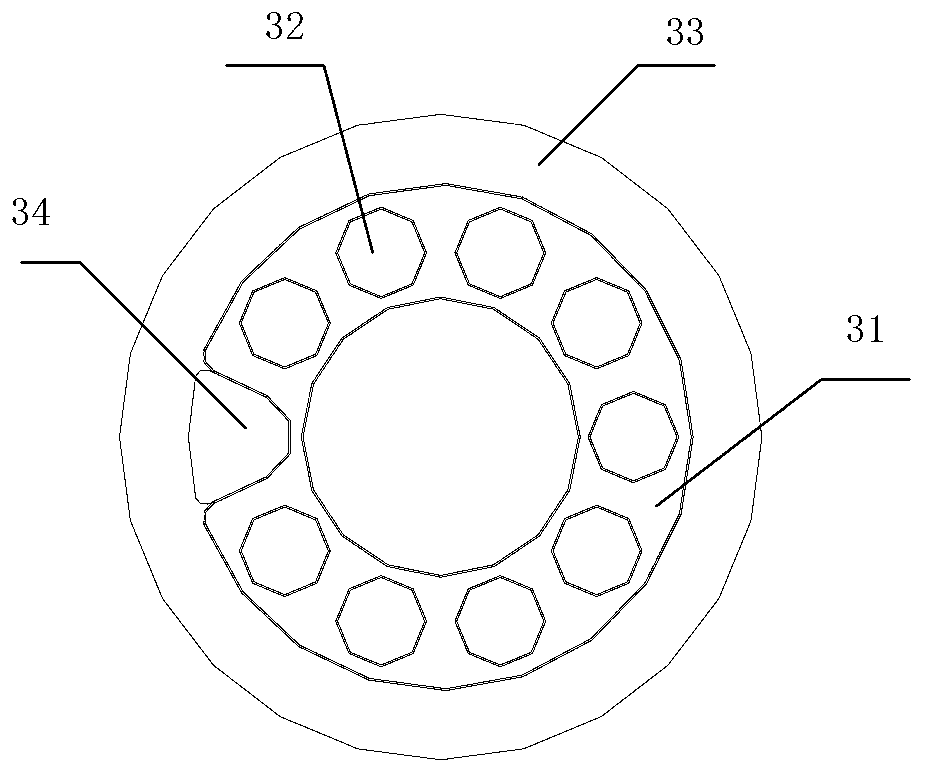

[0027] The invention provides a generalized slip ring rotor ring assembly, such as figure 2 As shown, it includes insulating ring 3 and metal ring 2. As shown in Figure 3 (a) and (b), the center of insulating ring 3 is processed with a center hole that matches the outer circle of mandrel 1 of the slip ring rotor. The outer side processes the annular boss, and the outer circle of the annular boss matches the inner circle of the metal ring 2; the ring between the outer circle of the bottom end of the annular boss 31 and the outer circle of the insulating ring 3 is used as a flash 33; A plurality of threading holes 32 of the same size are evenly opened in the circumferential direction; the number of threading holes 32 is determined according to the properties and types of the transmission current. When there are many types of current, different types of curr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com