High-strength cold-rolled steel sheet having excellent stretch flange properties, and process for production thereof

A technology of stretch flangeability and cold-rolled steel sheet, which is applied to the field of improvement of stretch flangeability, and can solve problems such as high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

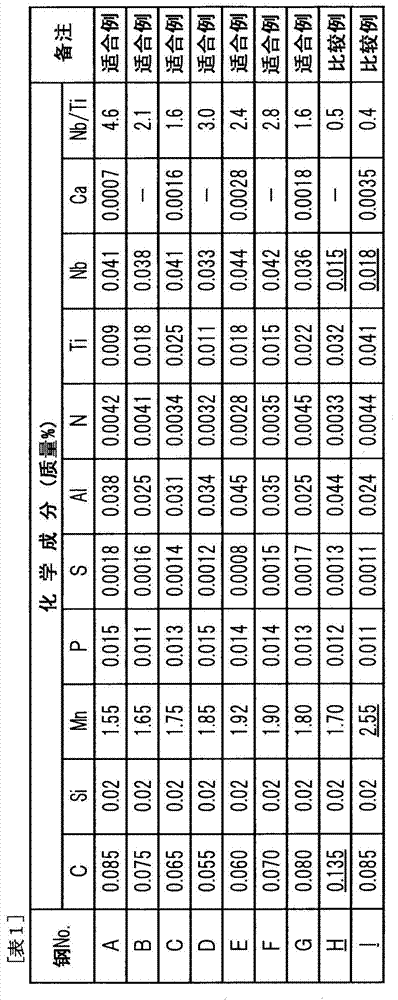

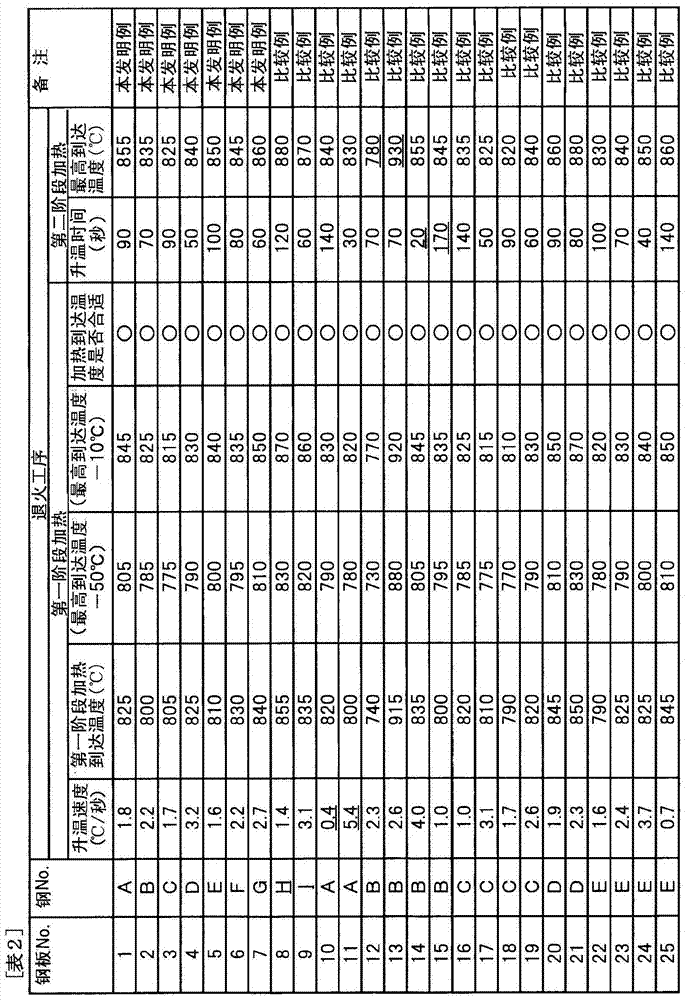

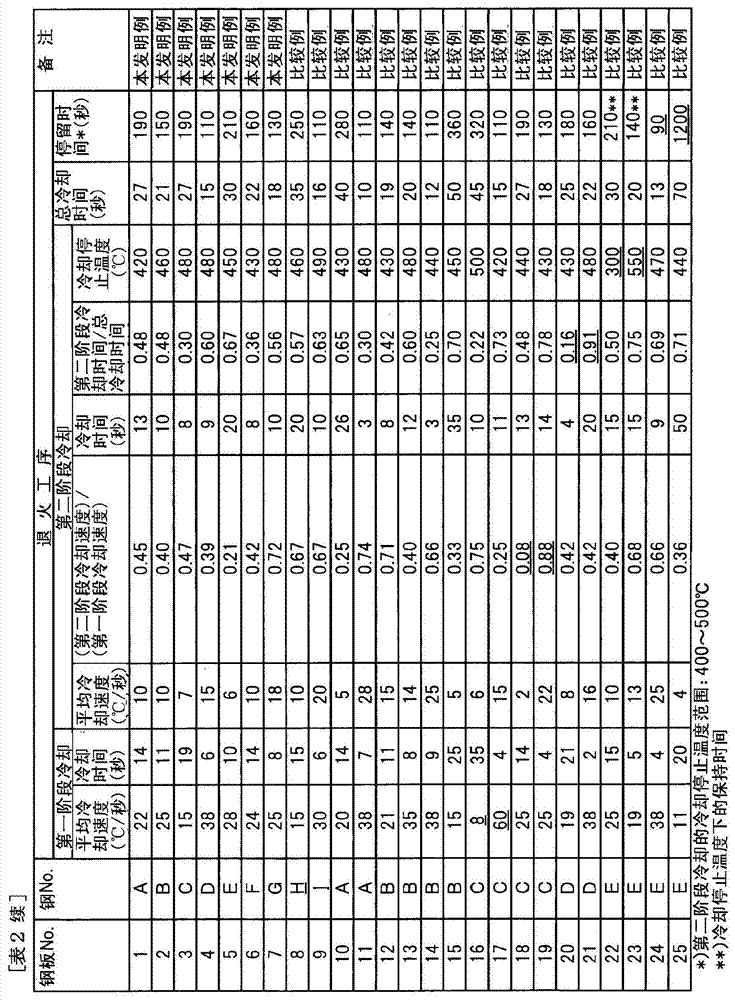

[0108] Hereinafter, the present invention will be described in detail based on examples.

[0109] Molten steel having the composition shown in Table 1 was melted in a converter, and cast into billets (steel raw materials) by continuous casting. A hot rolling process in which these steel raw materials (steel billets) are used as starting materials, heated to 1200°C, and then hot-rolled at a finishing temperature of 900°C and a coiling temperature of 600°C to form a hot-rolled sheet . Next, after the hot-rolled sheet was pickled with hydrochloric acid, it was cold-rolled to form a cold-rolled sheet, followed by annealing in which two-stage heating and two-stage cooling were performed under the conditions shown in Table 2. process to obtain a cold-rolled and annealed sheet with a thickness of 1.4 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com