Method for manufacturing silicon tetrachloride and method for manufacturing silicon for use in a solar cell

A technology of solar cells and manufacturing methods, applied in chemical instruments and methods, halogenated silicon compounds, inorganic chemistry, etc., to achieve the effect of stable and inexpensive provision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

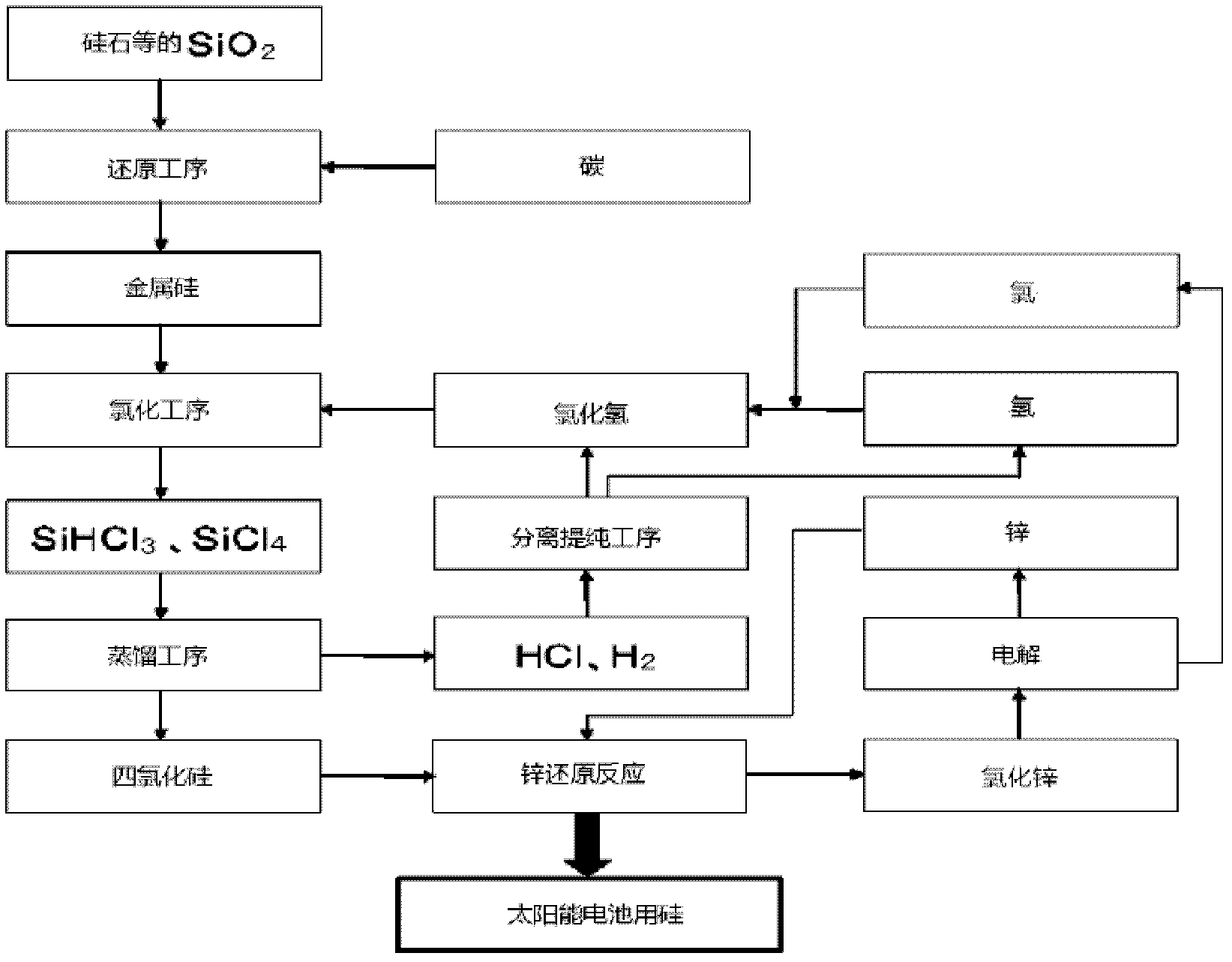

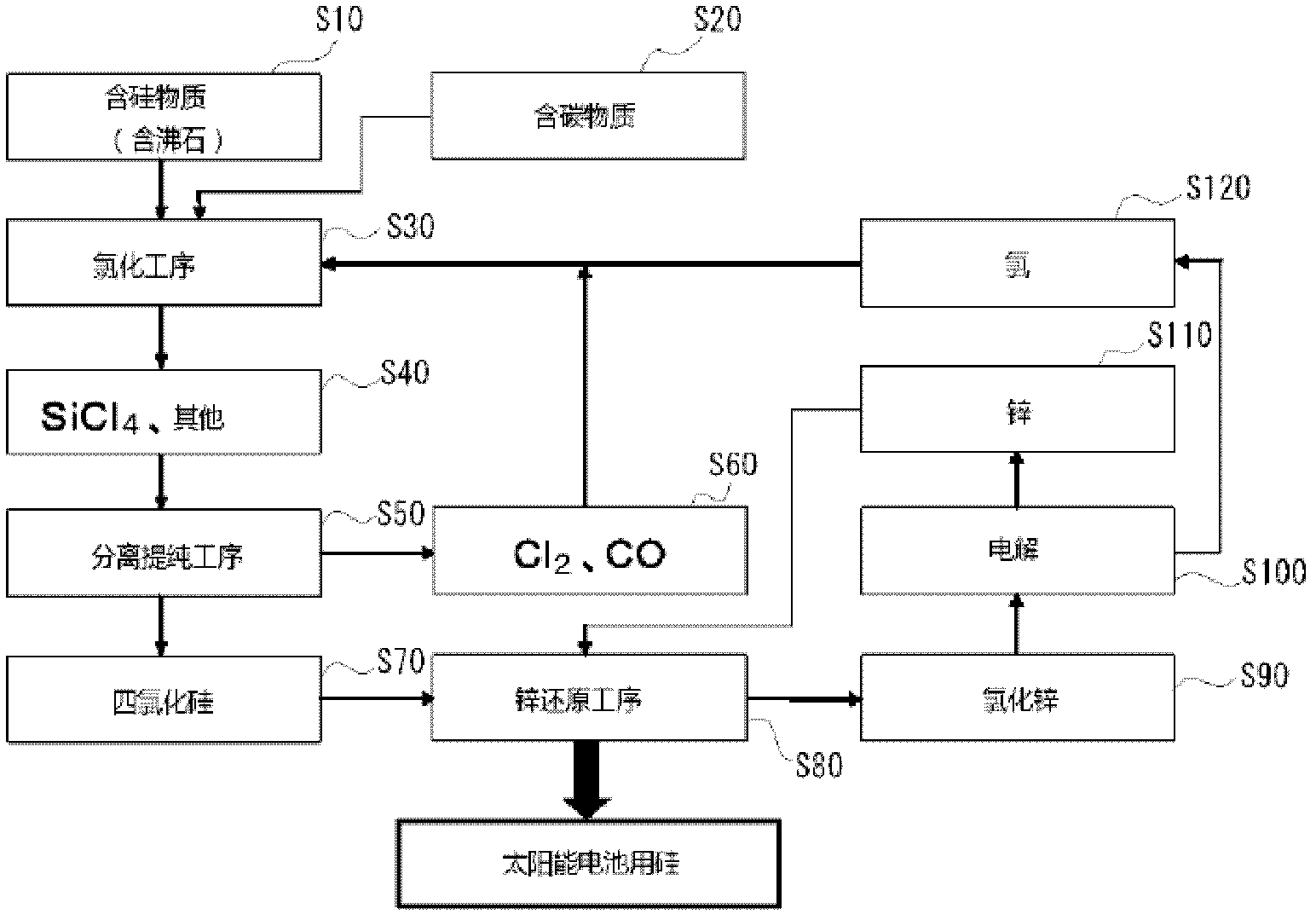

Method used

Image

Examples

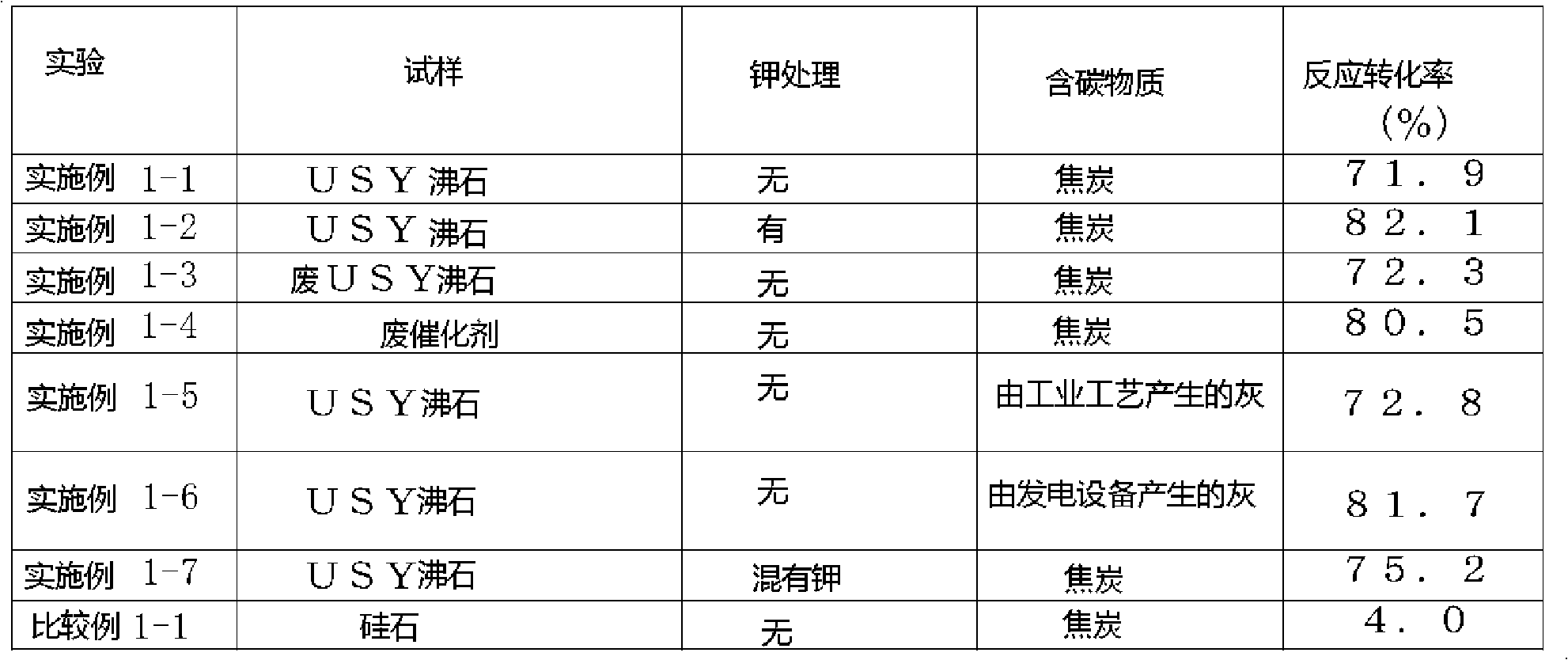

Embodiment 1-1

[0079] As the silicon-containing substance, 100 mg of USY zeolite (manufactured by Catalytic Chemicals, ratio of silicon to aluminum: 150) was used, and 39 mg of coke (manufactured by New Japan Petroleum Corporation, carbon content: 99.9% by mass or more) was used as the carbon-containing substance. The surface area of the USY zeolite (BET method) used is 570m 2 / g, the average pore size is The micropore capacity is 1.1 mL / g, the acid center is 0.5 mol / kg, and the coke is used after pulverizing a commercially available product through a ball mill. After the carbon-containing material is added to the silicon-containing material and mixed, a reaction mixture is obtained. It should be noted that the addition amount of the carbonaceous material and the number of moles of C contained in the reaction mixture satisfy the following formula (b).

[0080] The number of moles of C contained in the reaction mixture = 2A+3B...(b)

[0081] A: The number of moles of Si contained in the silico...

Embodiment 1-2

[0092] As the silicon-containing material, 100 mg of potassium-containing USY zeolite was used, and as the carbon-containing material, 39 mg of coke was used. The USY zeolite was ion-exchanged with a potassium hydroxide 10% aqueous solution (manufactured by Aldrich) to contain potassium, and its content was 3.2% by mass relative to the silica in the USY zeolite. The chlorination reaction was performed by contacting the reaction mixture with pure chlorine gas at 900° C. for 1 hour to obtain 250 mg of the product. The reaction conversion rate is shown in Table 5 below.

Embodiment 1-3

[0094] As the silicon-containing material, 100 mg of waste US Y zeolite was used, and as the carbon-containing material, 37 mg of coke was used. The waste USY zeolite used in this example was used as an ion exchange resin membrane. The reaction mixture was contacted with pure chlorine gas at 900° C. for 1 hour for chlorination reaction to obtain 228 mg of product. The reaction conversion rate is shown in Table 5 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com